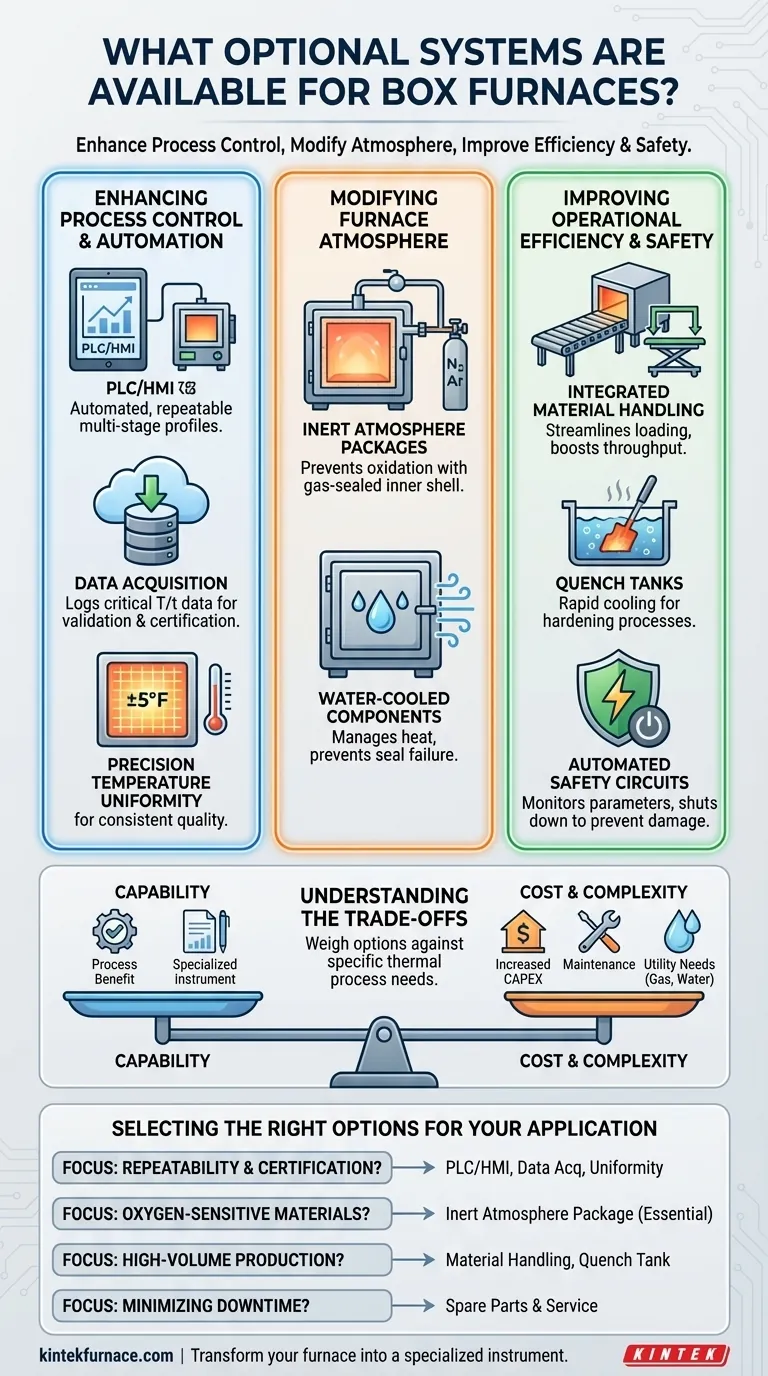

In short, optional systems for box furnaces focus on enhancing process control, modifying the internal atmosphere, and improving operational efficiency. The most common options include PLC/HMI controls for automation, inert gas systems for atmosphere control, data acquisition for process validation, and specialized features for improved temperature uniformity.

The key is to view these options not as a simple list of features, but as a toolkit for transforming a general-purpose furnace into a specialized instrument precisely tailored to your specific thermal process, be it tempering, annealing, or hardening.

Enhancing Process Control and Automation

The most significant upgrades focus on moving from manual oversight to automated, repeatable, and documented processes. This is critical for applications requiring high precision and certification.

PLC/HMI for Process Automation

A PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) replace standard timers and single-loop controllers. This allows for complex, multi-stage heating, soaking, and cooling profiles to be programmed and executed automatically.

This ensures that every part undergoes the exact same thermal cycle, which is essential for process repeatability and quality control.

Data Acquisition Systems

A data acquisition system logs critical process variables, most importantly temperature and time. This is not just for monitoring; it provides an auditable record of the process.

For industries like aerospace or medical manufacturing, this documentation is often a mandatory requirement for process validation and part certification.

Precision Temperature Uniformity

While a standard furnace might guarantee a temperature uniformity of ±25°F, many processes require much tighter control. Optional upgrades can achieve uniformities as precise as ±5°F.

This is achieved through advanced heater arrangements, baffle designs, and sophisticated control algorithms to ensure every part of the workspace is at the desired temperature.

Modifying the Furnace Atmosphere

Many heat-treating processes, such as annealing or brazing, require an environment free of oxygen to prevent oxidation, scaling, and discoloration of the parts.

Inert Atmosphere Packages

This is a comprehensive option that fundamentally alters the furnace construction. It typically includes a gas-sealed inner shell welded tight to prevent leaks.

To manage the heat, these systems also require water-cooled components, such as o-ring sealed doors and electrical terminal connections, to prevent seals from failing at high temperatures.

The system allows you to purge the air from the chamber and backfill it with an inert gas, such as nitrogen or argon, creating a controlled, non-reactive environment for the workpiece.

Improving Operational Efficiency and Safety

These options are focused on material handling, workflow integration, and protecting both personnel and equipment.

Integrated Material Handling

For production environments, hearth roller rails and external load tables streamline the process of loading and unloading heavy or bulky parts.

This reduces operator strain, minimizes the time the furnace door is open (saving energy), and increases overall throughput.

Quench Tanks

A quench tank can be integrated with the furnace setup to allow for rapid cooling of parts immediately after heat treatment. This is a critical step in hardening processes.

Having the quench tank nearby ensures a rapid transfer, which is crucial for achieving the desired metallurgical properties in the material.

Automated Safety Circuits

An automatic shutdown circuit is a key safety feature. It monitors critical furnace parameters and can safely power down the system in the event of an over-temperature condition or other malfunction.

This protects the furnace from damage, the parts from being ruined, and enhances the overall safety of the facility.

Understanding the Trade-offs

Adding optional systems provides greater capability but also introduces complexity and cost. It's crucial to weigh these factors.

Cost vs. Capability

Each option adds to the initial capital expenditure of the furnace. An inert atmosphere package, for example, is a significant investment due to the specialized construction required. You must ensure the process benefit justifies the cost.

Increased Complexity and Maintenance

A furnace with a PLC, water-cooling loops, and gas delivery systems is inherently more complex than a basic unit. This requires more sophisticated operational knowledge and a more involved preventative maintenance schedule.

Utility and Facility Requirements

Advanced options often come with their own infrastructure needs. An inert gas system requires a reliable supply of nitrogen or argon. Water-cooled doors and components require a steady source of cooling water and a drainage system.

Selecting the Right Options for Your Application

Choose your options based on the specific outcome you need to achieve.

- If your primary focus is process repeatability and certification: Prioritize a PLC/HMI control system, a data acquisition package, and an upgrade to tighter temperature uniformity.

- If your primary focus is processing materials sensitive to oxygen: The inert atmosphere package is not optional; it is a fundamental requirement for your application.

- If your primary focus is high-volume production: Invest in material handling options like hearth roller rails, load tables, and an integrated quench tank to maximize throughput.

- If your primary focus is minimizing downtime: A spare parts package and available field installation supervision are wise investments to ensure long-term reliability.

Ultimately, the right configuration transforms the furnace from a simple heated box into a critical component of your manufacturing process.

Summary Table:

| Optional System | Key Benefits |

|---|---|

| PLC/HMI Controls | Enables automated, repeatable multi-stage heating and cooling profiles for precise process control. |

| Inert Atmosphere Packages | Prevents oxidation and scaling by creating a controlled, non-reactive environment with inert gases. |

| Data Acquisition Systems | Logs temperature and time data for process validation and certification in regulated industries. |

| Precision Temperature Uniformity | Achieves tight control (e.g., ±5°F) for uniform heating across the workspace. |

| Integrated Material Handling | Streamlines loading/unloading with roller rails and load tables to boost throughput and safety. |

| Quench Tanks | Allows rapid cooling post-heat treatment for hardening processes, ensuring desired material properties. |

| Automated Safety Circuits | Monitors parameters and shuts down the furnace to prevent damage and enhance operational safety. |

Ready to optimize your thermal processes with a tailored box furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, enhancing efficiency and precision. Contact us today to discuss how we can transform your lab's capabilities!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control