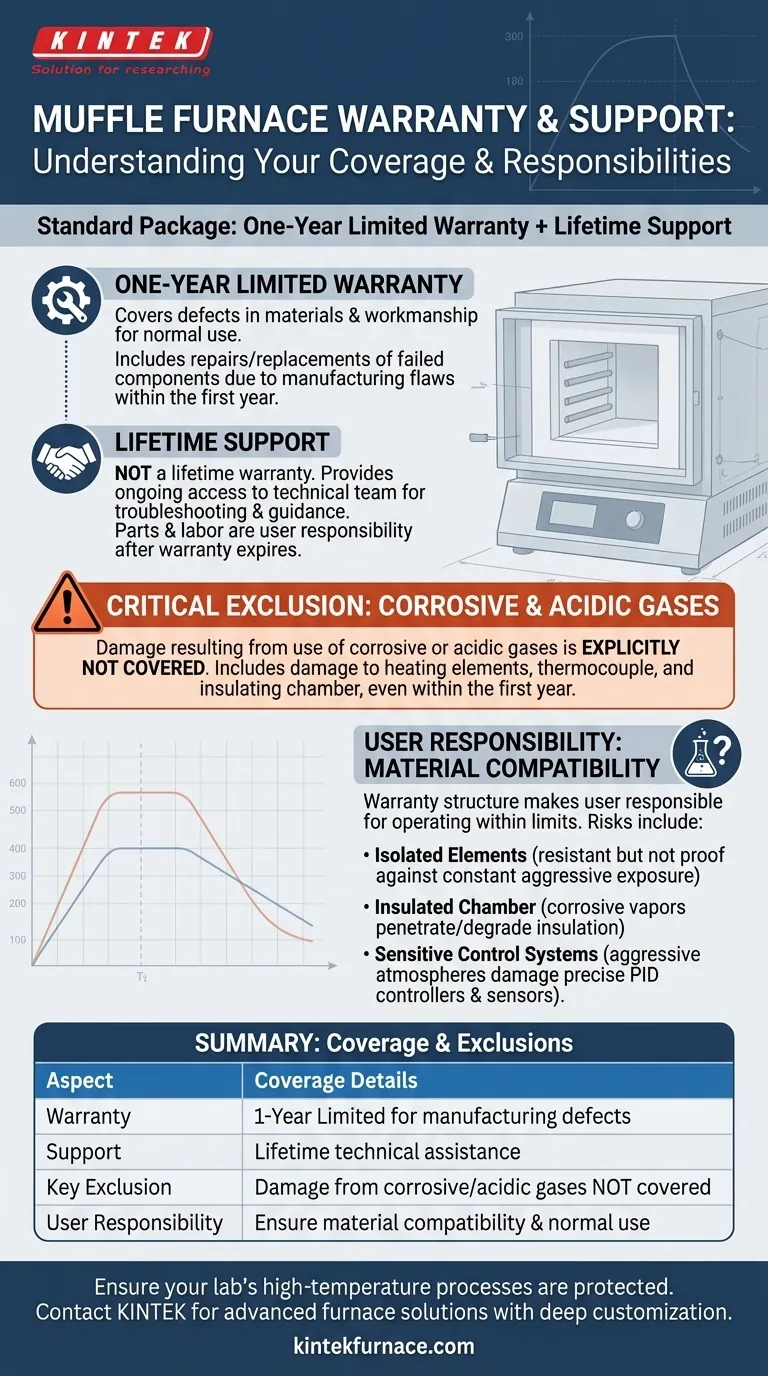

The standard muffle furnace package includes a one-year limited warranty and lifetime support from the manufacturer. However, it is critical to understand the limitations of this coverage, as any damage resulting from the use of corrosive or acidic gases is explicitly not covered by the warranty. This exclusion is the single most important factor to consider when evaluating the furnace for your specific application.

While a one-year warranty provides a baseline of security against manufacturing defects, the real risk lies in operational use. The warranty's exclusion for corrosive damage shifts the responsibility for material compatibility entirely to you, the user.

Deconstructing the Warranty and Support

Understanding the terms "limited warranty" and "lifetime support" is crucial. They are not the same and cover very different aspects of your ownership experience.

The One-Year Limited Warranty

A one-year limited warranty typically covers defects in materials and workmanship. If a component like a heating element or a controller fails due to a manufacturing flaw within the first year, it will be repaired or replaced.

This coverage is contingent on "normal use," which is defined by the manufacturer.

Understanding "Lifetime Support"

Lifetime support is not a lifetime warranty. It means you have access to the manufacturer's technical team for troubleshooting, operational questions, and guidance for the life of the product.

This can be valuable for diagnosing issues or ordering replacement parts, but the cost of those parts and any associated labor will be your responsibility after the one-year warranty expires.

The Critical Exclusion: Corrosive Environments

The most significant detail is the exclusion of damage from corrosive and acidic gases. Many laboratory and industrial processes, such as chemical digestion or ashing certain materials, can release vapors that are highly aggressive to metals and ceramics at high temperatures.

If your process releases these substances, any resulting damage to the heating elements, thermocouple, or insulating chamber will not be covered by the warranty, even within the first year.

Why Material Compatibility Is Your Responsibility

The furnace is designed with features to ensure performance and longevity, but these features have limits. The warranty's structure makes it clear that you are responsible for operating the equipment within those limits.

Isolated Elements and Resistant Linings

Muffle furnaces feature heating elements that are isolated from the chamber's interior. This is designed to prevent direct chemical reactions between the elements and your samples, ensuring sample purity and uniform heating.

While the chamber may be made of corrosion-resistant ceramic materials, "resistant" does not mean "proof." Constant exposure to an aggressive atmosphere at high temperatures will eventually lead to degradation.

The Role of the Insulated Chamber

The furnace's chamber is packed with high-density insulation, like a glass wool blanket, to achieve maximum thermal efficiency and temperature uniformity.

These insulating materials are chosen for their thermal properties, not their chemical inertness. Corrosive vapors can penetrate and degrade this insulation, compromising the furnace's performance and safety over time.

Sensitive Control Systems

Modern furnaces use precise PID (Proportional-Integral-Derivative) controllers and sensors to maintain exact temperatures. These are sophisticated electronic components.

An aggressive internal atmosphere can damage these sensitive controls, leading to inaccurate temperature regulation or outright failure. Such repairs fall outside the scope of the warranty.

Understanding the Trade-offs

Evaluating this furnace requires balancing its capabilities against the realities of its warranty coverage. A misunderstanding can lead to unexpected costs.

The Risk of Mismatched Application

The primary trade-off is cost versus application. This furnace is likely priced for general-purpose use in a non-corrosive atmosphere. Using it for an aggressive chemical process is a gamble.

While it may work for a time, you are accepting the full financial risk of premature failure.

Initial Inspection is Non-Negotiable

Upon receiving the furnace, you must inspect it immediately for any damage that may have occurred during shipping. Place it on a flat, stable surface and ensure all accessories are present.

Damage from shipping is typically covered if reported immediately, whereas a problem discovered months later will be much harder to claim.

Making the Right Choice for Your Application

To make an informed decision, match the warranty's limitations to your intended use case.

- If your primary focus is general heat treating, drying, or annealing in air: The standard one-year warranty provides sufficient coverage against defects for your low-risk application.

- If your primary focus is ashing or analysis with potentially corrosive byproducts: You must verify the chemical compatibility of your process with the furnace's materials and accept that any resulting damage is your financial responsibility.

- If your primary focus is a process known to be highly corrosive: You should invest in a specialized furnace that is explicitly designed and warrantied for use with those specific chemicals.

Understanding the limits of the warranty is the first step to ensuring the long-term reliability and value of your investment.

Summary Table:

| Aspect | Coverage Details |

|---|---|

| Warranty | One-year limited warranty for manufacturing defects |

| Support | Lifetime technical support for troubleshooting and guidance |

| Key Exclusion | Damage from corrosive or acidic gases not covered |

| User Responsibility | Ensure material compatibility and normal use to avoid voiding warranty |

Ensure your lab's high-temperature processes are fully protected with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique needs. Contact us today to discuss how our expertise can enhance your experimental reliability and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation