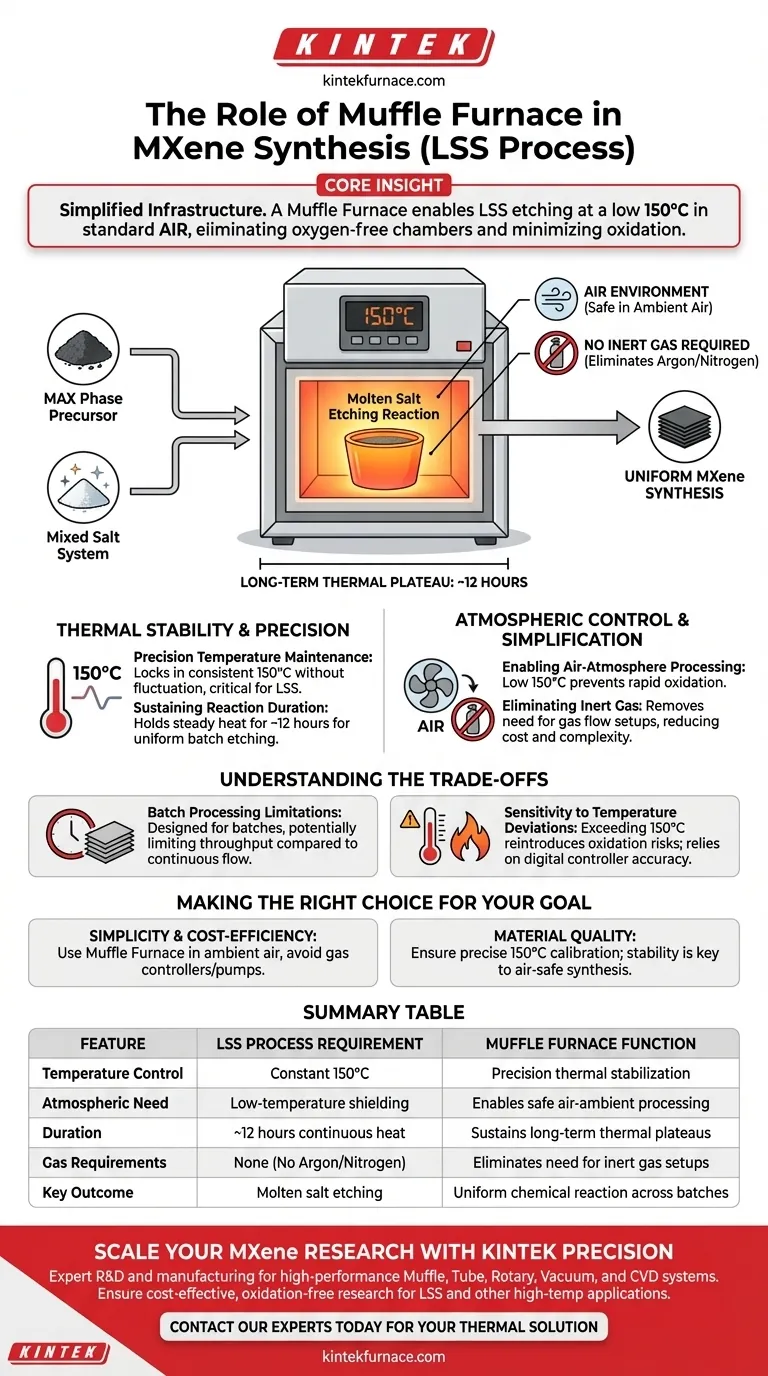

A Muffle Furnace functions as the critical thermal stabilizer in the Low-temperature Shielding Salt (LSS) synthesis of MXene, specifically maintaining a constant reaction environment at 150°C. By providing precise heat regulation for approximately 12 hours, it enables the molten salt etching reaction to proceed efficiently in a standard air environment without requiring complex inert gas protection.

Core Insight: The unique advantage of using a Muffle Furnace in the LSS process is the simplification of experimental infrastructure. Because the furnace facilitates etching at a significantly lower temperature (150°C) than traditional methods, it eliminates the need for oxygen-free chambers, allowing for safe synthesis in ambient air while minimizing material oxidation risks.

The Role of Thermal Stability in LSS Synthesis

Precision Temperature Maintenance

The primary technical function of the Muffle Furnace is to lock in a consistent 150°C operating temperature.

Unlike open heating methods, the insulated chamber ensures that the MAX phase precursor and the mixed salt system remain at this specific thermal plateau without fluctuation.

Sustaining Reaction Duration

The LSS process requires a prolonged reaction time, typically around 12 hours, to complete the etching process.

The Muffle Furnace is designed to hold steady temperatures over long durations, ensuring the chemical interaction between the salts and the precursor is uniform throughout the entire batch.

Atmospheric Control and Process Simplification

Enabling Air-Atmosphere Processing

In many material synthesis protocols, high heat requires vacuum or inert gas to prevent burning or rapid oxidation.

However, because the Muffle Furnace maintains the LSS process at a low 150°C, the reaction can occur safely in an air environment.

Eliminating Inert Gas Requirements

The stability provided by the furnace at this low temperature removes the need for inert gas protection (such as Argon or Nitrogen flow).

This drastically simplifies the experimental setup, reducing both equipment cost and the complexity of the laboratory procedure.

Understanding the Trade-offs

Batch Processing Limitations

Muffle furnaces are inherently designed for batch processing rather than continuous flow synthesis.

While excellent for research and small-scale production, this setup may limit throughput speed compared to continuous industrial heating methods.

Sensitivity to Temperature Deviations

While the LSS process allows for air processing at 150°C, significantly exceeding this temperature within the furnace could reintroduce oxidation risks.

The user must rely on the furnace's digital controller to ensure the temperature does not spike, as the "shielding" effect of the process relies on maintaining this low thermal profile.

Making the Right Choice for Your Goal

To maximize the efficacy of your MXene synthesis, apply the equipment capability to your specific objective:

- If your primary focus is Simplicity and Cost-Efficiency: Use the Muffle Furnace to run the LSS process in ambient air, avoiding the expense of gas flow controllers and vacuum pumps.

- If your primary focus is Material Quality: Ensure your furnace is calibrated to hold exactly 150°C, as stability is the key to preventing oxidation without inert gas.

The Muffle Furnace transforms MXene synthesis from a complex, high-energy procedure into a manageable, low-temperature benchtop process.

Summary Table:

| Feature | LSS Process Requirement | Muffle Furnace Function |

|---|---|---|

| Temperature Control | Constant 150°C | Precision thermal stabilization |

| Atmospheric Need | Low-temperature shielding | Enables safe air-ambient processing |

| Duration | ~12 hours continuous heat | Sustains long-term thermal plateaus |

| Gas Requirements | None (No Argon/Nitrogen) | Eliminates need for inert gas setups |

| Key Outcome | Molten salt etching | Uniform chemical reaction across batches |

Scale Your MXene Research with KINTEK Precision

Ready to simplify your material synthesis? Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of MXene production. Whether you need precise 150°C stability for LSS processes or fully customizable lab high-temp furnaces for unique applications, our equipment ensures your research remains cost-effective and oxidation-free.

Take the next step in laboratory efficiency—contact our experts today to find your perfect thermal solution!

Visual Guide

References

- Sin‐Yi Pang, Jianhua Hao. Fluoride‐Free Molten Salt Hydrate‐Assisted Synthesis of MXene in Air Down to 150 °C. DOI: 10.1002/adfm.202504864

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What materials are used in a box type resistance furnace's structure? Discover the Key Materials for Durability and Efficiency

- What makes crucible furnaces suitable for high-temperature applications? Achieve Unmatched Purity and Precision

- What function does a muffle furnace serve in the synthesis of glass derived from rice husk ash? High-Temp Precision

- What are the key features of box type electric furnaces in heat treatment processes? Achieve Precise Thermal Control for Superior Metallurgy

- How is a muffle furnace utilized in environmental analysis? Essential for Precise Organic and Inorganic Composition Testing

- What benefits do box furnaces offer in terms of material properties? Achieve Superior Material Control and Performance

- What precautions should be taken when handling samples in the muffle furnace? Ensure Safety and Extend Equipment Life

- What technological advantages do modern muffle furnaces offer? Achieve Precision and Purity in Thermal Processing