To safely handle samples in a muffle furnace, you must use the correct tools like crucible tongs, never introduce wet samples, and scrupulously manage temperature changes. The most critical procedures involve the cool-down phase: after cutting power, you must allow the furnace to cool gradually by cracking the door open slightly before fully opening it to remove samples. This prevents catastrophic equipment damage from thermal shock.

The core principle of muffle furnace safety is managing extreme temperature differentials. Failing to respect the physics of thermal shock not only risks ruining your sample but can cause permanent damage to the furnace and create a significant hazard for the operator.

Before You Begin: Preparing the Furnace and Sample

Proper preparation is the first line of defense against accidents and equipment failure. A disciplined setup minimizes risks before the heating process even starts.

Ensure a Safe Operating Environment

Your furnace must be on a stable, level surface like a cement platform, away from any flammable or explosive materials. Ensure it is properly grounded with appropriate electrical connections to prevent electrical hazards.

Use Appropriate, Clean Containers

Samples must be placed in high-temperature-resistant containers, such as porcelain crucibles. Crucially, you must never introduce samples containing water or oil, and ensure any tools used for handling are also completely dry and clean to prevent violent reactions or explosions at high temperatures.

Place Samples with Care

When loading the furnace, use crucible tongs and place the sample container gently inside. You must take extreme care to avoid touching the thermocouple, the slender temperature-sensing probe that extends into the chamber. It is very fragile at high temperatures and can easily break.

During High-Temperature Operation

Once the furnace is at temperature, your interaction with it must be minimal and deliberate. The risks are highest during this phase.

Never Open the Door Above 600°C

Opening the furnace door while the internal temperature is extremely high (above 600°C is a common guideline) introduces a rush of cool air. This sudden temperature drop can cause the furnace's refractory materials to crack, leading to irreparable damage.

Monitor for Abnormalities

Pay close attention to the temperature controller. If you observe unexpected temperature spikes or other irregularities, cut the power immediately and investigate the cause once the unit has safely cooled.

Avoid Sample Splashing

Control your heating rates according to your material's properties. Heating a sample too quickly can cause it to splash or sputter, which can corrode the furnace hearth or bond to its surface, making it difficult to clean and maintain.

The Critical Cool-Down and Removal Process

How you cool the furnace and remove your sample is just as important as how you heat it. This is where most equipment damage occurs.

Cut Power and Wait

Once your heating process is complete, turn off the main power supply. Do not, under any circumstances, open the furnace door immediately.

The "Crack-Open" Technique for Gradual Cooling

To prevent thermal shock, you must allow the furnace to cool slowly. The best practice is to open the furnace door just a small slit. This allows heat to escape gradually without causing a sudden, damaging temperature drop.

Use Proper Tools for Removal

Only after the furnace temperature has fallen significantly should you fully open the door. Use long crucible tongs to carefully remove your sample and place it on a heat-resistant surface to finish cooling.

Understanding the Trade-offs: Why These Rules Matter

These precautions are not arbitrary; they are based on the physical and chemical principles at play at extreme temperatures.

Thermal Shock: The Silent Equipment Killer

The single greatest threat to a muffle furnace's longevity is thermal shock. Refractory ceramics, while excellent at handling high heat, are brittle and cannot withstand rapid temperature changes. Opening a hot furnace is like pouring cold water into a hot glass dish—the material contracts unevenly and cracks.

The Fragile Thermocouple: Your Temperature Gauge

The thermocouple is the furnace's nerve center. It provides the temperature feedback necessary for accurate control. Bumping or breaking it means you lose all ability to regulate the process, rendering the furnace useless until it is repaired.

The Danger of Volatiles: Water and Oil

Introducing a liquid like water or oil into a hot furnace (well above its boiling point) causes it to flash-vaporize into steam almost instantly. This rapid expansion of volume creates a pressure spike—an explosion—that can damage the furnace and cause serious injury.

Making the Right Choice for Your Goal

Adherence to protocol should be tailored to your primary objective, whether it's safety, equipment preservation, or sample purity.

- If your primary focus is operator safety: The most critical rules are never opening the door above 600°C and ensuring samples are free of water or oil.

- If your primary focus is equipment longevity: Your priority is managing thermal shock by cooling gradually and carefully avoiding contact with the thermocouple during loading.

- If your primary focus is sample integrity: Use clean, high-temperature-resistant crucibles and control heating rates to prevent splashing, contamination, or loss of material.

Mastering the use of a muffle furnace is achieved through a deep respect for its power and a disciplined adherence to procedure.

Summary Table:

| Precaution | Key Details |

|---|---|

| Use Proper Tools | Employ crucible tongs for safe handling to avoid burns and damage. |

| Avoid Wet Samples | Never introduce water or oil to prevent explosions and violent reactions. |

| Manage Temperature Changes | Cool gradually by cracking the door open to prevent thermal shock. |

| Protect Thermocouple | Avoid contact during loading to maintain accurate temperature control. |

| Monitor During Operation | Watch for abnormalities and cut power if issues arise for safety. |

Need reliable high-temperature solutions for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental needs—enhancing safety, efficiency, and results. Contact us today to discuss how our tailored solutions can benefit your laboratory!

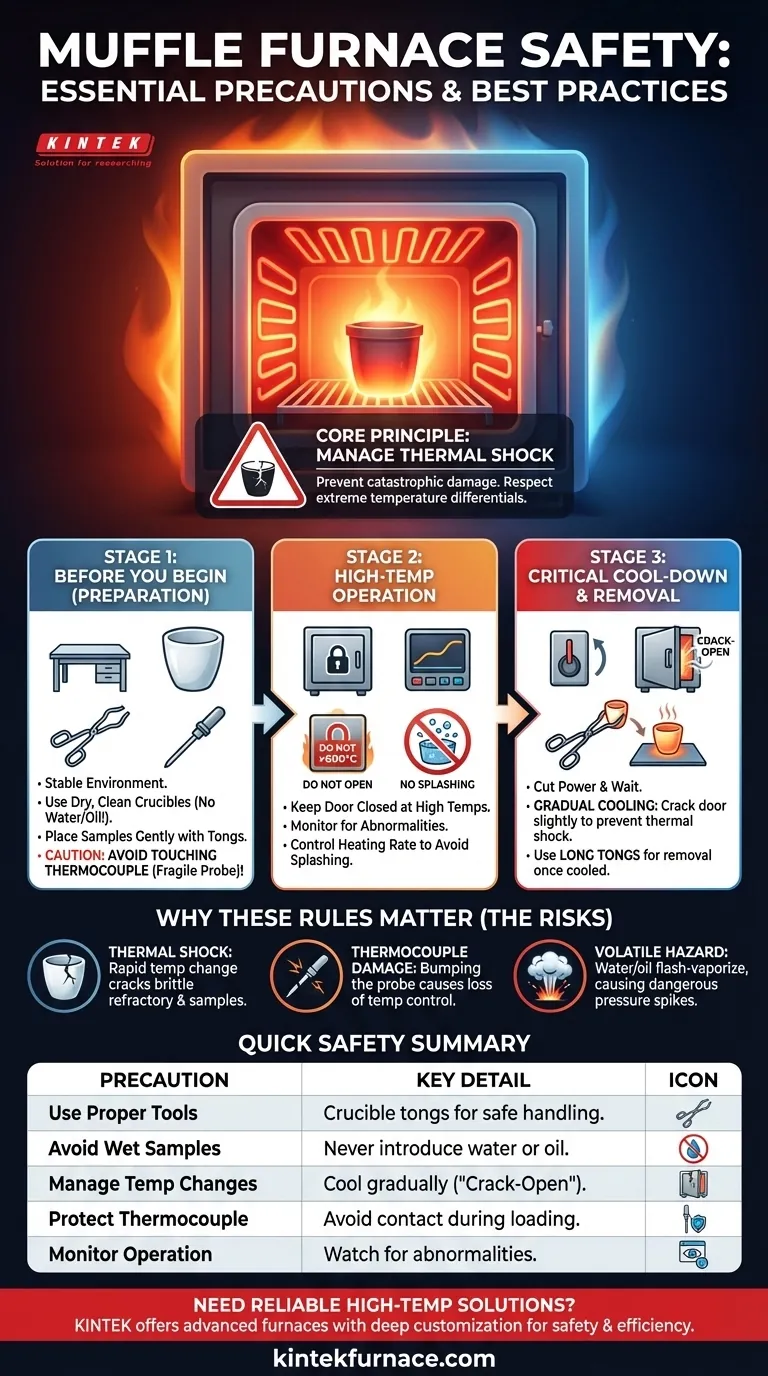

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure