Crucible furnaces excel in high-temperature applications because of their specialized design, which combines extreme heat generation with precise environmental control. They can reach temperatures sufficient to melt materials with very high melting points, such as refractory metals and superalloys, while maintaining a controlled atmosphere to prevent contamination and oxidation.

The primary reason to choose a crucible furnace for high-temperature work is not just its ability to reach extreme heat, but its capacity to protect the material's integrity throughout the process. It excels where both the target temperature and the final material purity are non-negotiable.

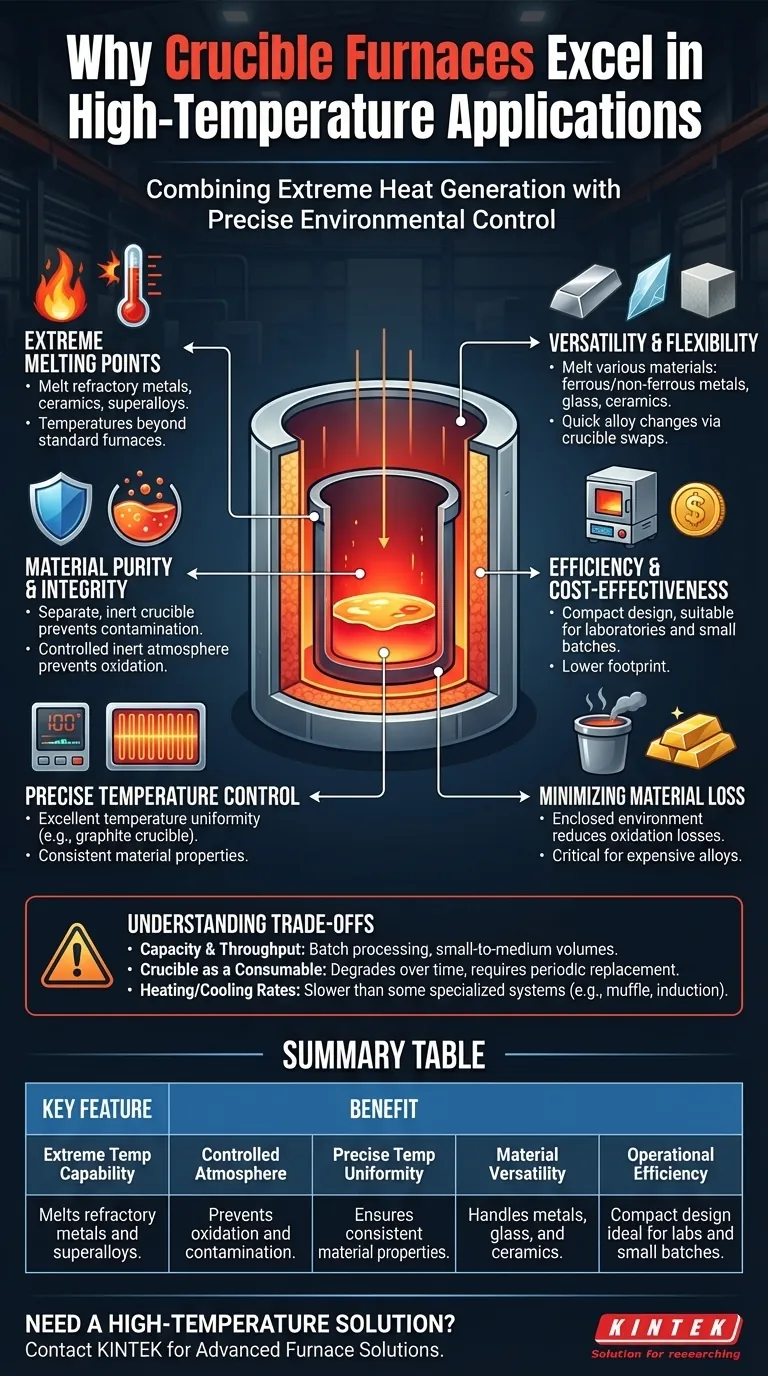

The Core Pillars of High-Temperature Performance

A crucible furnace’s suitability is built on three fundamental capabilities that work in concert. These features ensure that demanding materials can be processed effectively and without degradation.

Achieving Extreme Melting Points

Crucible furnaces are engineered to operate at temperatures that standard furnaces cannot sustain.

This makes them essential for melting and processing advanced materials like refractory metals, certain ceramics, and high-temperature alloys that are fundamental to aerospace, medical, and industrial applications.

Ensuring Material Purity and Integrity

The design inherently protects the material being processed. By using a separate, often inert, crucible, the risk of cross-contamination between different melts is virtually eliminated.

Furthermore, these furnaces can maintain an inert atmosphere during the heating cycle. This prevents oxidation and other unwanted chemical reactions, which is critical when working with reactive materials like superalloys.

Maintaining Precise Temperature Control

High temperature alone is not enough; control is paramount. Graphite crucible furnaces, in particular, provide excellent temperature uniformity throughout the crucible.

This precise management ensures the entire melt reaches and holds the target temperature, resulting in consistent and predictable material properties in the final product.

Operational Advantages in Demanding Environments

Beyond its core thermal performance, the crucible furnace offers practical benefits that make it a preferred choice in many lab and production settings.

Versatility Across Materials

A single crucible furnace can be used to melt a wide range of materials, from ferrous and non-ferrous metals to glass and advanced ceramics.

The ability to perform quick alloy changes simply by swapping the crucible makes it highly adaptable for research, development, and small-batch production environments.

Efficiency in Targeted Operations

Crucible furnaces are often more compact and cost-effective than larger industrial furnace types. Their design is well-suited for laboratories and small-scale operations that require high performance without a massive footprint.

Minimizing Material Loss

The enclosed, controlled environment significantly reduces oxidation losses. This is a critical financial consideration when working with expensive metals and alloys.

Understanding the Trade-offs

No technology is a universal solution. It is crucial to understand the limitations of a crucible furnace to make an informed decision.

Capacity and Throughput

Crucible furnaces are typically designed for batch processing and are best suited for small-to-medium volumes. They are not designed for the continuous, large-scale melting operations where induction or arc furnaces excel.

The Crucible as a Consumable

The crucible itself is a consumable component. Over time, it will degrade from thermal stress and chemical interaction, requiring periodic replacement. This represents a recurring operational cost that must be factored into any budget.

Heating and Cooling Rates

While effective, the heating and cooling cycles of a crucible furnace may be slower compared to other specialized systems like muffle or induction furnaces. For applications demanding extremely fast thermal cycling, this can be a limiting factor.

Making the Right Choice for Your Application

Selecting the correct furnace depends entirely on your primary objective. Use these points as a guide for your decision.

- If your primary focus is material purity for special alloys: A crucible furnace's ability to provide an inert atmosphere and prevent contamination is its greatest strength.

- If your primary focus is versatility for R&D or small-batch production: The compact design and ability to handle a wide range of materials make it an ideal, cost-effective choice.

- If your primary focus is reaching the highest possible temperatures for refractory materials: A crucible furnace is one of the few technologies capable of reliably achieving the necessary thermal conditions for these demanding jobs.

By understanding these core capabilities and limitations, you can confidently determine if a crucible furnace is the optimal tool to achieve your high-temperature goals.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Extreme Temperature Capability | Melts refractory metals and superalloys. |

| Controlled Atmosphere | Prevents oxidation and contamination. |

| Precise Temperature Uniformity | Ensures consistent material properties. |

| Material Versatility | Handles metals, glass, and ceramics. |

| Operational Efficiency | Compact design ideal for labs and small batches. |

Need a high-temperature furnace solution tailored to your unique requirements?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced furnace solutions for diverse laboratories. Our product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities.

Whether your priority is material purity for special alloys, versatility for R&D, or reaching extreme temperatures, we can design a solution that precisely meets your experimental needs.

Contact our experts today to discuss how we can enhance your high-temperature processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision