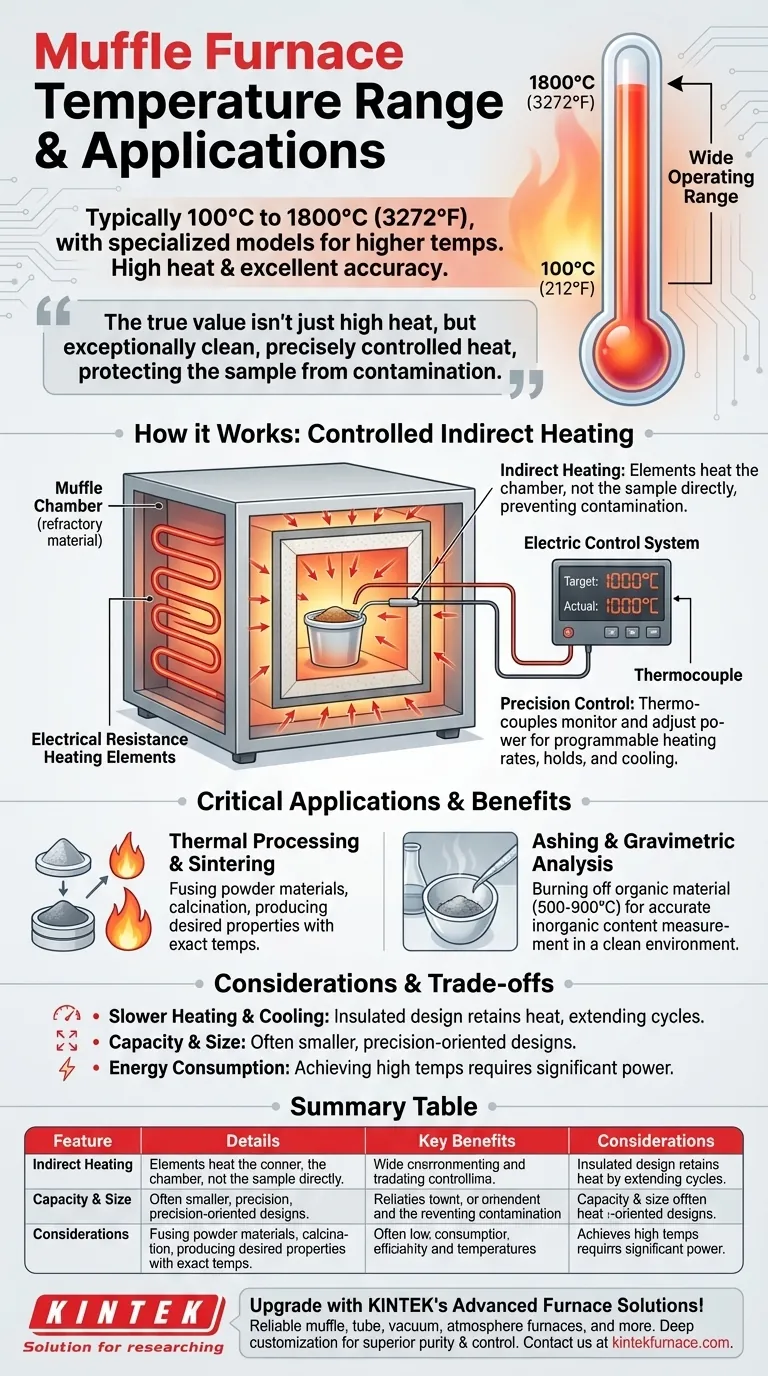

As a general rule, a muffle furnace operates within a wide temperature range, typically from 100°C (212°F) up to 1800°C (3272°F), with some specialized models capable of even higher temperatures. This extensive range, combined with excellent temperature accuracy, makes it a highly versatile tool for a variety of demanding thermal processes.

The true value of a muffle furnace isn't just its high temperature capability, but its ability to deliver that heat in an exceptionally clean and precisely controlled environment, protecting the sample from any contamination.

How a Muffle Furnace Delivers Controlled Heat

The key to the furnace's performance lies in its name. The "muffle" is a specialized chamber that isolates the material being heated from the heating elements and other outside influences.

The Principle of Indirect Heating

A muffle furnace works by heating the chamber, not the sample directly. Electrical resistance heating elements are positioned outside of a sealed, insulated chamber (the muffle).

This design creates a buffer, preventing any byproducts from the heating elements or atmosphere from contaminating the sample inside. This is critical for applications where purity is paramount.

The Role of the "Muffle" Chamber

The muffle itself is constructed from high-temperature, heat-resistant refractory materials. This chamber serves two primary functions.

First, it protects the heating elements from any fumes or off-gassing that the sample may produce. Second, it ensures uniform heat distribution, radiating heat evenly from all sides to prevent hot spots and ensure the entire sample experiences the same temperature.

Precision Temperature Control

Modern muffle furnaces are managed by sophisticated electric control systems. These systems use thermocouples to constantly monitor the internal temperature and adjust the power to the heating elements.

This feedback loop allows for precise programming of heating rates, holding times at specific temperatures, and controlled cooling, which is essential for repeatable scientific and industrial processes.

Why the Temperature Range is Critical for Applications

The specific temperature range and control of a muffle furnace make it indispensable for processes that require both high heat and high purity.

Thermal Processing and Sintering

Applications like sintering (fusing powder materials together with heat) or calcination (heating solids to high temperatures to drive off substances) rely on achieving and holding exact temperatures to produce the desired material properties.

Ashing and Gravimetric Analysis

In analytical chemistry, muffle furnaces are used for ashing. This process involves burning off all organic material in a sample at high temperatures (typically 500-900°C) to accurately measure the inorganic content (ash) that remains.

The clean heating environment is vital here, as it ensures that only the sample's components are being measured, with no external contaminants.

Understanding the Trade-offs

While powerful, the design of a muffle furnace comes with certain considerations.

Heating and Cooling Rates

Because it relies on indirect heating, a muffle furnace can have slower heating and cooling cycles compared to a direct-fire furnace. The insulated chamber that ensures stability also retains heat, meaning it takes longer to cool down.

Capacity and Size

Muffle furnaces are often designed for laboratory or small-batch production. While larger industrial models exist, the precision-oriented design can limit the internal chamber capacity.

Energy Consumption

Achieving and maintaining temperatures of 1000°C or higher requires a significant amount of electrical energy. The high-quality insulation helps with efficiency, but they are energy-intensive machines by nature.

Making the Right Choice for Your Application

To determine if a muffle furnace is the right tool, consider your primary objective.

- If your primary focus is analytical purity (e.g., ashing, trace metal analysis): The muffle furnace is ideal due to its isolated chamber, which prevents sample contamination.

- If your primary focus is precise material transformation (e.g., sintering, crystal growing): The furnace's uniform heating and excellent temperature control make it a superior choice.

- If your primary focus is rapid, high-volume heat treatment: You may need to evaluate whether the processing time of a muffle furnace aligns with your production goals compared to direct-fire alternatives.

Ultimately, a muffle furnace is the standard for when high heat and high precision must be achieved without compromise.

Summary Table:

| Feature | Details |

|---|---|

| Temperature Range | Typically 100°C to 1800°C, with specialized models exceeding this |

| Key Benefits | Clean, contamination-free heating; precise temperature control; uniform heat distribution |

| Common Applications | Ashing, sintering, calcination, gravimetric analysis, thermal processing |

| Considerations | Slower heating/cooling rates; limited capacity in some models; high energy consumption |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering superior purity and control. Contact us today to discuss how we can enhance your thermal processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis