Fundamentally, box-type high-temperature resistance furnaces are defined by their versatility. They are engineered to accommodate a vast range of workpieces, from small, intricate components to large molds and fixtures. The suitability of a workpiece is determined not by a rigid list of types, but by its material composition, physical dimensions, and the specific atmospheric conditions required for its heat treatment.

The core consideration is not "what can fit inside," but "what are the precise thermal and atmospheric conditions required for the process?" The furnace's suitability for a workpiece is ultimately a function of its temperature range, uniformity, and its capability for atmospheric control.

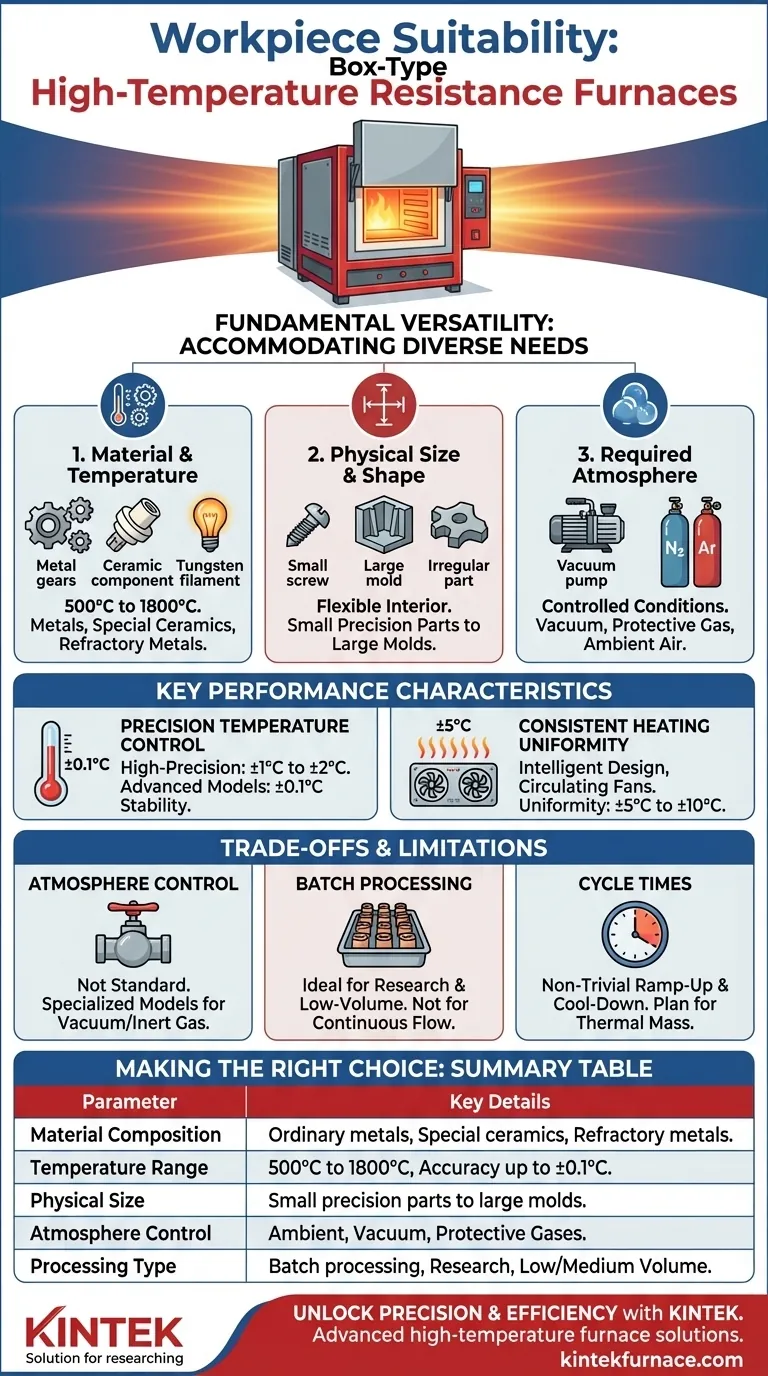

The Three Pillars of Workpiece Suitability

To determine if this furnace is the right tool for your needs, evaluate your workpiece against three key operational parameters.

1. Material Composition and Temperature Requirements

Box-type resistance furnaces offer a wide operational temperature range, typically from 500°C to 1800°C.

This range makes them suitable for the heat treatment requirements of diverse materials, including:

- Ordinary Metals: Steels and alloys requiring annealing, quenching, or tempering.

- Special Ceramics: Sintering, debinding, and firing of advanced ceramic components.

- Refractory Metals: High-temperature processing of materials like tungsten and molybdenum.

2. Physical Size and Shape

The furnace's name describes its primary advantage: a spacious and regularly shaped interior.

This design provides exceptional flexibility, allowing for the processing of a wide variety of workpiece geometries, from small precision parts to large, bulky molds. The uniform internal space simplifies loading and supports even heating.

3. Required Process Atmosphere

The process atmosphere is a critical factor that separates standard models from specialized units.

While a standard box furnace operates in ambient air, many applications require controlled conditions. Some models can be equipped with sealed structures and atmosphere control devices to perform heat treatments under specific environments like:

- Vacuum: To prevent oxidation and degas materials.

- Protective Gas: Using inert gases like nitrogen or argon to protect sensitive materials from reacting with air at high temperatures.

Key Performance Characteristics That Ensure Quality

Beyond basic suitability, the furnace's performance specifications directly impact the quality and repeatability of the heat treatment process.

High-Precision Temperature Control

These furnaces are equipped with high-precision temperature control systems. It is common to achieve a control accuracy of ±1°C to ±2°C.

For applications demanding the highest level of exactness, some advanced models can even maintain temperature stability within ±0.1°C, ensuring process requirements are met without deviation.

Consistent Heating Uniformity

Proper heat treatment requires the entire workpiece to experience the same temperature. Through intelligent structural design, strategic placement of heating elements, and the use of internal circulating fans, these furnaces achieve excellent temperature uniformity.

A typical specification for temperature uniformity across the chamber is within ±5°C to ±10°C, which prevents hot spots and ensures consistent material properties throughout the part.

Understanding the Trade-offs and Limitations

To make a fully informed decision, you must also understand the inherent trade-offs of the box-type design.

Standard vs. Specialized Atmosphere Control

Atmosphere control is a crucial differentiator and not a standard feature. If your process requires a vacuum or an inert gas environment, you must select a model specifically designed or equipped for it. A standard furnace cannot be retrofitted easily or effectively for these tasks.

Batch Processing, Not Continuous Flow

The design of a box furnace is inherently for batch processing. Workpieces are loaded, the door is closed, the thermal cycle is run, and then the batch is unloaded.

This is ideal for research, prototyping, or low-to-medium volume production. It is not suitable for high-volume, continuous manufacturing workflows, where a conveyor or tunnel furnace would be more efficient.

Inherent Cycle Times

Due to their thermal mass, these furnaces have non-trivial ramp-up and cool-down times. These periods must be factored into your total processing time and operational planning. They are not designed for instantaneous heating or cooling.

Making the Right Choice for Your Application

Use your primary goal to guide your selection.

- If your primary focus is general-purpose heat treatment of metals or ceramics in air: A standard box-type furnace with good temperature uniformity is an excellent and versatile choice.

- If your primary focus is processing sensitive alloys or materials prone to oxidation: A model equipped with vacuum or protective atmosphere control is non-negotiable.

- If your primary focus is achieving extremely tight material properties: Prioritize models offering the highest level of temperature control precision (e.g., ±0.1°C) and a documented uniformity report.

- If your primary focus is high-volume, continuous production: The batch-oriented nature of a box furnace is likely a mismatch for your needs; explore continuous furnace types instead.

By aligning the furnace's capabilities with your specific material and process requirements, you can confidently select the right tool for the job.

Summary Table:

| Parameter | Key Details |

|---|---|

| Material Composition | Suitable for ordinary metals (e.g., steels), special ceramics, refractory metals (e.g., tungsten) |

| Temperature Range | 500°C to 1800°C, with control accuracy up to ±0.1°C |

| Physical Size | Accommodates small precision parts to large molds, with uniform heating |

| Atmosphere Control | Options include ambient air, vacuum, or protective gases (e.g., nitrogen) |

| Processing Type | Batch processing, ideal for research and low-to-medium volume production |

Unlock Precision and Efficiency in Your Heat Treatment Processes

At KINTEK, we specialize in delivering advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, our product line—including Box-Type, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed for versatility and reliability. With strong deep customization capabilities, we ensure precise alignment with your experimental requirements, whether you're working with metals, ceramics, or other materials.

Contact us today to discuss how our furnaces can enhance your lab's performance and achieve superior results. Get in touch now!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- Why is a laboratory high-temperature box furnace essential for KNN ceramic powders? Mastering Solid-State Synthesis