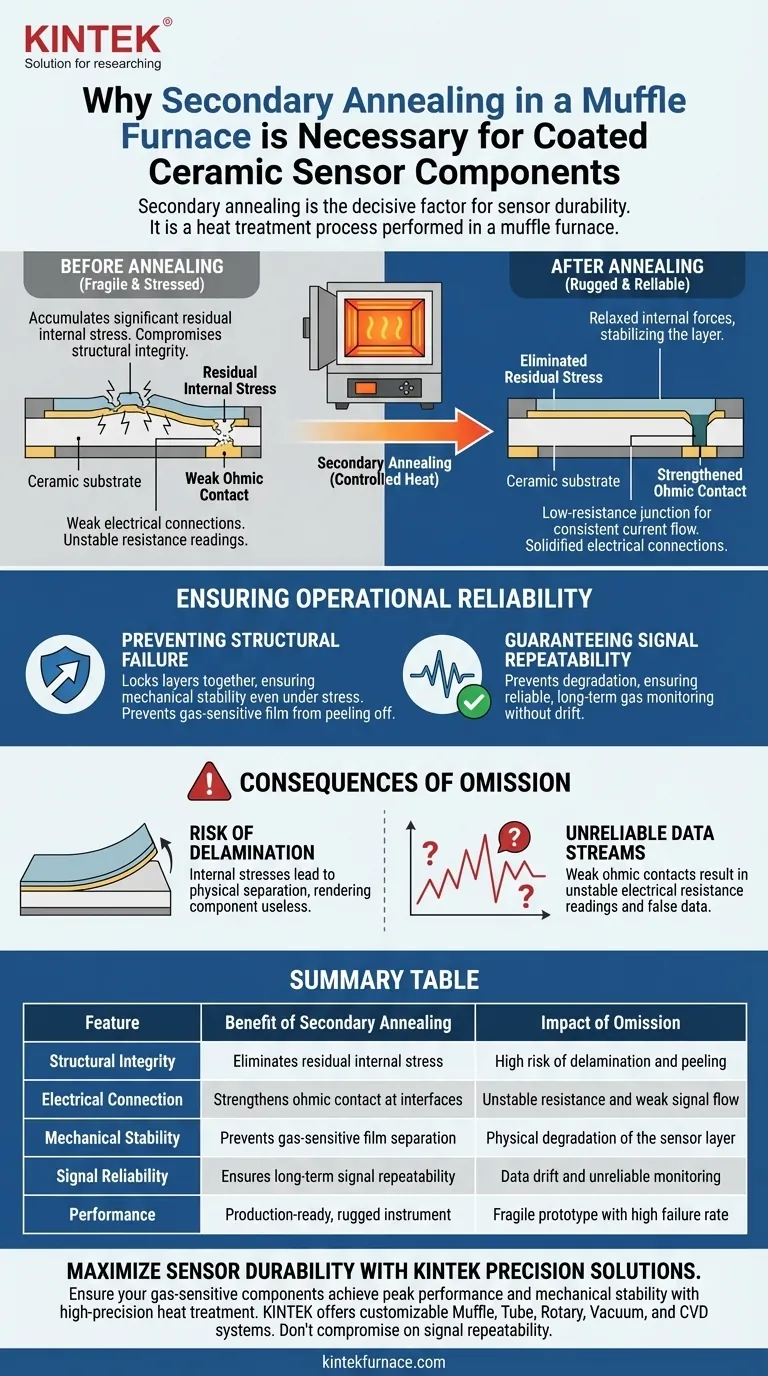

Secondary annealing is the decisive factor for sensor durability. It is a heat treatment process performed in a muffle furnace to eliminate residual internal stresses within the gas-sensitive layer of coated ceramic components. Furthermore, it is essential for strengthening the ohmic contact between the sensitive material, the ceramic substrate, and the electrodes.

Secondary annealing serves a dual purpose: it relaxes internal structural tension and solidifies electrical connections. This ensures the sensor remains mechanically stable and delivers repeatable signals during long-term monitoring.

Addressing the Physical Challenges

To understand the necessity of this treatment, one must look at the physical state of the sensor immediately after coating.

Eliminating Internal Stress

During the initial coating process, the gas-sensitive layer often accumulates significant residual internal stress.

If left untreated, this tension compromises the structural integrity of the material. Secondary annealing uses controlled heat to relax these internal forces, stabilizing the layer.

Strengthening Ohmic Contact

A sensor's accuracy relies heavily on how well its components connect electrically.

The annealing process strengthens the ohmic contact—the low-resistance junction essential for current flow.

This bonding occurs at the critical interface between the sensitive material, the ceramic substrate, and the electrodes.

Ensuring Operational Reliability

Beyond the physical structure, secondary annealing directly impacts how the sensor performs in real-world applications.

Preventing Structural Failure

The primary risk for untreated sensors is mechanical degradation.

Without annealing, the gas-sensitive film is prone to peeling off the substrate.

The heat treatment locks the layers together, ensuring mechanical stability even under stress.

Guaranteeing Signal Repeatability

For a sensor to be useful, it must provide consistent data over time.

By preventing degradation and film detachment, annealing ensures signal repeatability.

This allows for reliable, long-term gas monitoring without the drift caused by physical deterioration.

The Consequences of Omission

While adding a secondary heat treatment step requires time and energy resources, the trade-off of skipping it is severe.

Risk of Delamination

Omitting this step leaves the internal stresses active within the coating.

This inevitably leads to delamination, where the sensitive layer physically separates from the ceramic base, rendering the component useless.

Unreliable Data Streams

Weak ohmic contacts result in unstable electrical resistance readings.

Without the solidification provided by annealing, the sensor cannot maintain the precision required for accurate monitoring, leading to false data and unreliable performance.

Applying This to Your Process

The decision to anneal is ultimately about the difference between a prototype and a production-ready device.

- If your primary focus is mechanical durability: Prioritize annealing to relieve stress and prevent the gas-sensitive film from peeling.

- If your primary focus is data precision: Ensure the heat treatment is sufficient to solidify the ohmic contact for consistent signal repeatability.

This process transforms a coated ceramic component from a fragile part into a rugged, reliable instrument capable of long-term operation.

Summary Table:

| Feature | Benefit of Secondary Annealing | Impact of Omission |

|---|---|---|

| Structural Integrity | Eliminates residual internal stress | High risk of delamination and peeling |

| Electrical Connection | Strengthens ohmic contact at interfaces | Unstable resistance and weak signal flow |

| Mechanical Stability | Prevents gas-sensitive film separation | Physical degradation of the sensor layer |

| Signal Reliability | Ensures long-term signal repeatability | Data drift and unreliable monitoring |

| Performance | Production-ready, rugged instrument | Fragile prototype with high failure rate |

Maximize Sensor Durability with KINTEK Precision Solutions

Ensure your gas-sensitive components achieve peak performance and mechanical stability with high-precision heat treatment. KINTEK provides industry-leading muffle and vacuum furnaces specifically designed to eliminate internal stress and solidify critical ohmic contacts in ceramic sensors.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory or production requirements. Don't compromise on signal repeatability; partner with a leader in high-temperature technology to deliver rugged, reliable instruments.

Contact KINTEK Today to Optimize Your Annealing Process

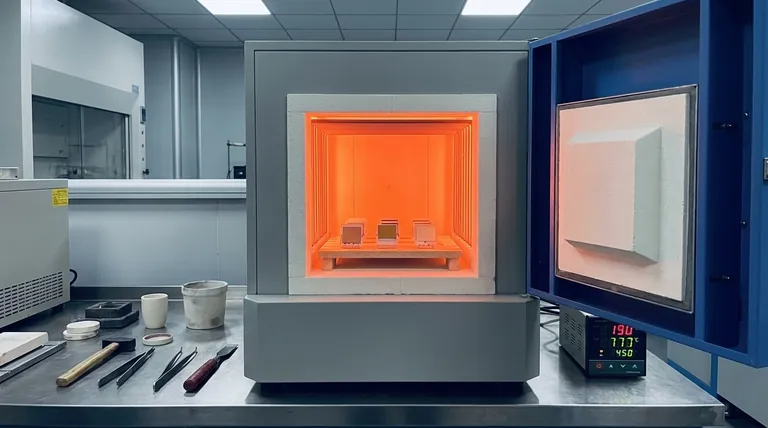

Visual Guide

References

- Peishuo Wang, Xueli Yang. Engineering Hierarchical CuO/WO3 Hollow Spheres with Flower-like Morphology for Ultra-Sensitive H2S Detection at ppb Level. DOI: 10.3390/chemosensors13070250

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is a Muffle Furnace with Hydrogen atmosphere? Achieve Oxide-Free, Bright Metal Finishes

- What other applications do muffle furnaces have? Unlock Versatile Uses in Labs and Manufacturing

- What industries commonly use muffle furnaces for high-temperature testing? Essential Tools for Materials Science, Chemistry, and More

- What industries commonly use industrial muffle furnaces? Unlock Precision Heating for Diverse Sectors

- Why are muffle furnaces particularly suitable for ashing processes? Achieve Contaminant-Free Sample Analysis

- How do vacuum muffle furnaces improve lab efficiency? Boost throughput with precise atmospheric control

- What role does a muffle furnace play in Pd1/CeO2 atom-trapping? Optimize Single-Atom Catalyst Synthesis

- What process conditions does a muffle furnace provide for aerogel reverse engineering? Unlock Material Reactivation