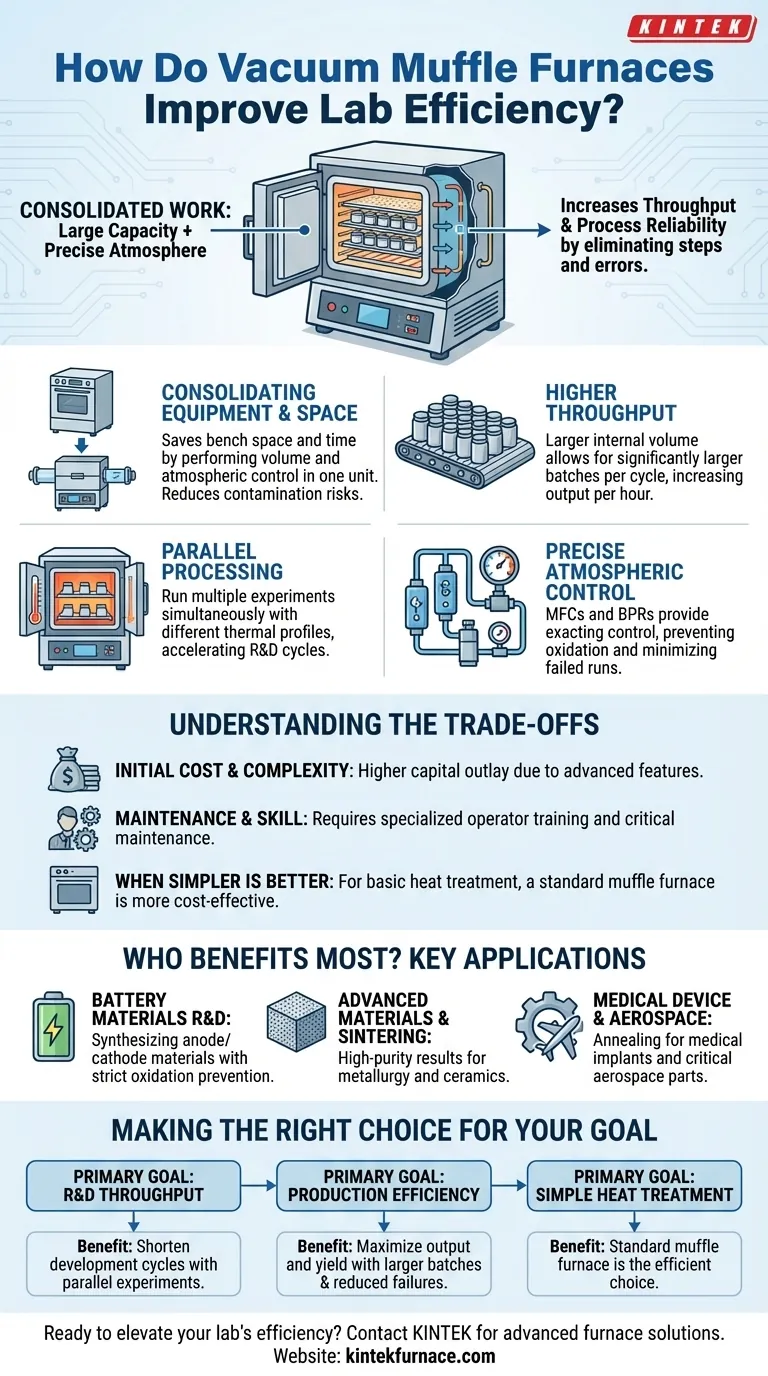

To put it simply, vacuum muffle furnaces improve lab efficiency by consolidating the work of multiple pieces of equipment into one. They blend the large sample capacity of a traditional muffle furnace with the precise atmospheric control of a tube furnace, allowing you to process more samples, with greater accuracy, in less time.

The core efficiency gain from a vacuum muffle furnace is not just about speed; it's about increasing throughput and process reliability. By combining high volume with precise atmospheric control, these furnaces eliminate entire steps and sources of error in advanced materials processing.

The Core Mechanisms of Efficiency

A vacuum muffle furnace is more than an oven; it is an integrated processing environment. Its efficiency stems from a combination of design principles that directly address common laboratory bottlenecks.

Consolidating Equipment and Space

A key benefit is the ability to perform tasks that would otherwise require both a muffle furnace (for volume) and a tube furnace (for atmospheric control).

This consolidation reduces the lab's equipment footprint, freeing up valuable bench space. It also saves the time and eliminates the risk of contamination associated with transferring samples between different machines.

Achieving Higher Throughput

By design, muffle furnaces offer a larger internal volume than most tube furnaces.

This allows for the processing of significantly larger sample batches or larger individual components in a single cycle. For production-oriented labs, this directly translates to higher output per hour.

Enabling Parallel Processing

Advanced vacuum muffle furnaces can create distinct temperature zones within the chamber.

This unique feature allows researchers to run multiple experiments simultaneously under different thermal profiles in a single run. This dramatically accelerates R&D cycles and increases experimental throughput.

Ensuring Precise Atmospheric Control

Components like Mass Flow Controllers (MFCs) and Back Pressure Regulators (BPRs) provide exacting control over the gas environment.

This precision is critical for preventing oxidation and other unwanted reactions. By ensuring the process atmosphere is perfect from the start, the furnace minimizes failed runs, saving significant time, materials, and energy.

Understanding the Trade-offs

While highly efficient, these systems are a strategic investment and are not a universal solution for every lab. Objectivity requires acknowledging their specific demands.

Initial Cost and Complexity

A vacuum muffle furnace is a more complex and expensive piece of equipment than a standard air-atmosphere furnace. The initial capital outlay is higher, reflecting its advanced capabilities.

Maintenance and Operational Skill

The integrated vacuum systems, gas controllers, and advanced programming require a higher level of operator training. Proper maintenance is also more involved, yet critical, to ensure long-term reliability and accurate performance.

When Simpler is Better

For applications that only require simple heat treatment in air and do not need strict atmospheric control, a basic muffle furnace is often a more direct and cost-effective tool. The efficiency gains of a vacuum system are irrelevant if its features are not needed.

Who Benefits Most? Key Applications

The efficiency of a vacuum muffle furnace is most pronounced in labs working with sensitive, high-value materials that demand controlled environments.

Battery Materials R&D

These furnaces are essential for synthesizing anode and cathode materials, where preventing oxidation is non-negotiable for achieving desired electrochemical properties.

Advanced Materials and Sintering

Labs performing vacuum or inert-gas sintering for metallurgy, ceramics, and materials science research rely on these systems for process repeatability and high-purity results.

Medical Device and Aerospace

The ability to anneal alloy powders for medical implants or heat-treat critical steel and titanium parts for aerospace requires the strict atmospheric and thermal uniformity that these furnaces provide.

Making the Right Choice for Your Goal

To determine if this investment is right for you, consider your primary operational bottleneck.

- If your primary focus is R&D throughput: The ability to run parallel experiments and ensure process repeatability will drastically shorten your development cycles.

- If your primary focus is production efficiency: The combination of larger batch volume and reduced failure rates from precise control will maximize your output and yield.

- If your primary focus is simple heat treatment: The additional complexity and cost are likely unnecessary, and a standard muffle furnace remains the most efficient choice.

By understanding these core principles, you can confidently determine if a vacuum muffle furnace is the right strategic investment to elevate your lab's capabilities.

Summary Table:

| Efficiency Factor | Key Benefit |

|---|---|

| Equipment Consolidation | Combines muffle and tube furnace functions, saving space and reducing contamination risks |

| Higher Throughput | Large sample capacity allows bigger batches, increasing output per cycle |

| Parallel Processing | Multiple temperature zones enable simultaneous experiments, speeding R&D |

| Precise Atmospheric Control | Mass Flow Controllers and Back Pressure Regulators prevent oxidation, reducing failures |

Ready to elevate your lab's efficiency with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our solutions can boost your throughput and reliability!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control