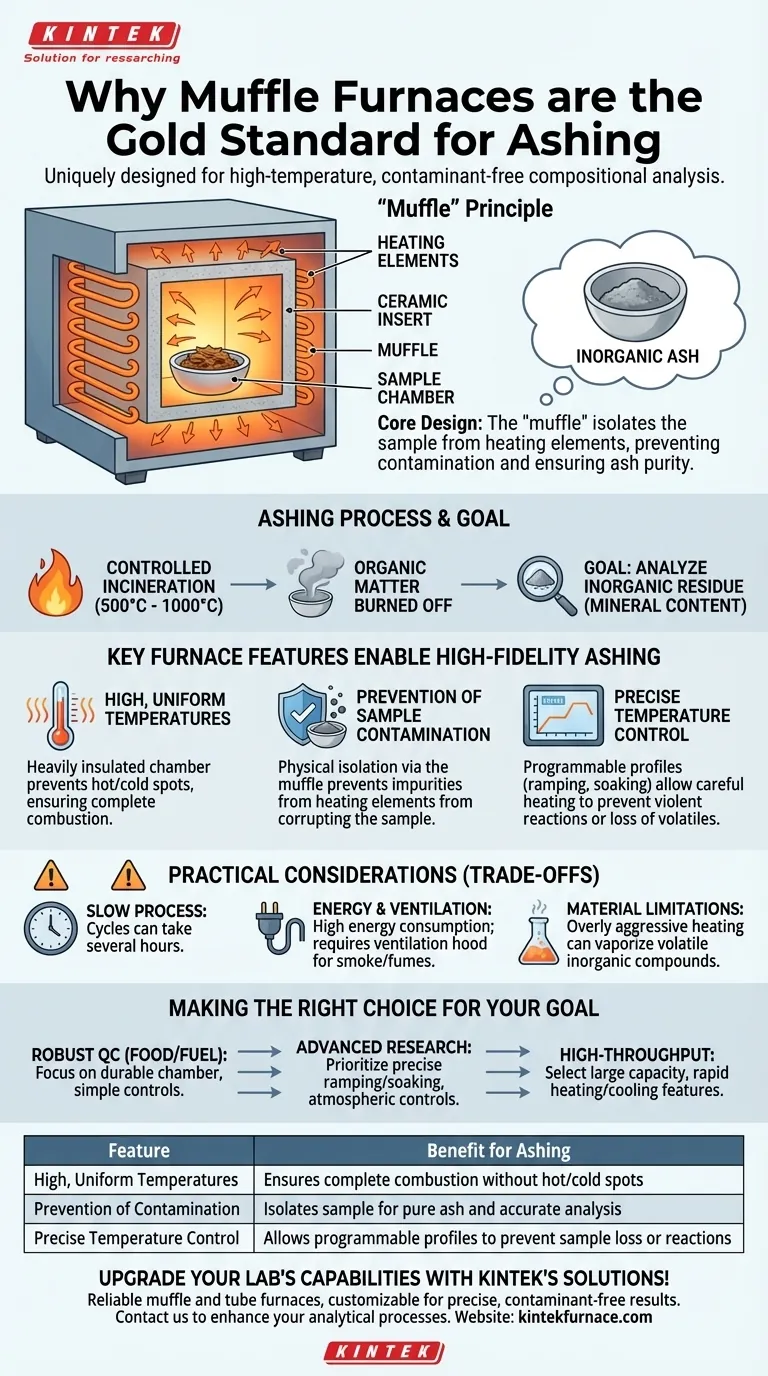

For any laboratory tasked with compositional analysis, the muffle furnace is the definitive instrument for ashing. Its design is uniquely suited to achieving the high, consistent temperatures needed to burn away organic material, all while isolating the sample from potential contaminants to ensure the purity of the final inorganic ash.

A muffle furnace excels at ashing because its core design principle—the "muffle"—separates the heating elements from the sample chamber. This prevents contamination, ensuring that the remaining ash is a true representation of the sample's inorganic content after being subjected to precise, high-temperature combustion.

What is Ashing and Why is it Performed?

Before examining the furnace itself, it's crucial to understand the goal of ashing. It is a fundamental process in analytical chemistry.

The Ashing Process Defined

Ashing is a method of controlled incineration.

A sample is placed in the furnace and heated to a high temperature, typically between 500°C and 1000°C, to completely burn away all organic matter.

The Goal: Analyzing Inorganic Residue

The material left behind after complete combustion is known as ash.

This inorganic residue is then weighed or analyzed to determine the mineral content of foods, the amount of non-combustible filler in polymers, or the composition of fuels and pharmaceuticals.

Key Furnace Features That Enable High-Fidelity Ashing

A muffle furnace is not simply a hot box; its specific design features are what make it the ideal tool for this sensitive analytical technique.

High, Uniform Temperatures

Complete combustion of organic material requires immense and evenly distributed heat.

Muffle furnaces are heavily insulated, allowing them to reach and sustain the high temperatures required while ensuring there are no hot or cold spots within the chamber. This uniformity guarantees that the entire sample ashes completely.

Prevention of Sample Contamination

This is the most critical feature of a muffle furnace and the origin of its name.

The heating elements are located outside the primary sample chamber, separated by a high-temperature ceramic insert, or "muffle."

This design physically isolates the sample from the heating elements. It prevents flakes of metal oxide or other impurities from the elements from falling into and contaminating the sample, which would corrupt the final analysis.

Precise Temperature Control

Modern muffle furnaces offer precise digital control over the heating profile.

This allows technicians to program specific heating rates (ramping) and holding times (soaking). This control is vital, as some samples must be heated slowly to prevent violent reactions or the loss of volatile mineral components.

Understanding the Trade-offs

While ideal for ashing, muffle furnaces are specialized tools with practical considerations.

Process Duration

Ashing is inherently a slow process. Depending on the sample size, material, and target temperature, a complete cycle can take several hours.

Energy and Ventilation Requirements

Reaching and maintaining temperatures of over 900°C requires a significant amount of electrical energy.

Furthermore, the combustion process releases smoke and potentially hazardous fumes. The furnace must be operated under a ventilation hood or in a well-ventilated area to ensure operator safety.

Material Limitations

While excellent for most organic materials, care must be taken with samples containing highly volatile inorganic compounds. Overly aggressive heating can cause these elements to vaporize along with the organic matter, leading to inaccurate results.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the specific demands of your analytical work.

- If your primary focus is routine quality control (e.g., food or fuel analysis): A robust furnace with a durable chamber and simple, reliable temperature controls is most effective.

- If your primary focus is advanced materials research: Prioritize a programmable furnace with precise control over temperature ramps and soaks, and consider models with atmospheric controls.

- If your primary focus is high-throughput analysis: Select a model with a larger chamber capacity and features designed for rapid heating and cooling cycles to maximize productivity.

Ultimately, the muffle furnace provides the controlled, contaminant-free environment essential for converting a sample into pure ash for accurate analysis.

Summary Table:

| Feature | Benefit for Ashing |

|---|---|

| High, Uniform Temperatures | Ensures complete combustion of organic material without hot/cold spots |

| Prevention of Sample Contamination | Isolates sample from heating elements for pure ash and accurate analysis |

| Precise Temperature Control | Allows programmable ramping and soaking to prevent sample loss or reactions |

Upgrade your laboratory's ashing capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable muffle furnaces, tube furnaces, and more, all customizable to meet your unique experimental needs. Ensure contaminant-free, precise results—contact us today to discuss how our products can enhance your analytical processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization