At its core, the primary difference between a muffle furnace and a vacuum furnace is the method used to protect a material during heating. A muffle furnace prevents contamination by physically isolating the material from the heating elements inside a sealed chamber (the "muffle"). In contrast, a vacuum furnace achieves an even higher level of purity by actively removing the entire atmosphere from the chamber, eliminating reactive gases like oxygen.

The choice between these furnaces is not about which is "better," but which method of protection your material requires. A muffle furnace isolates from contaminants, while a vacuum furnace removes them entirely.

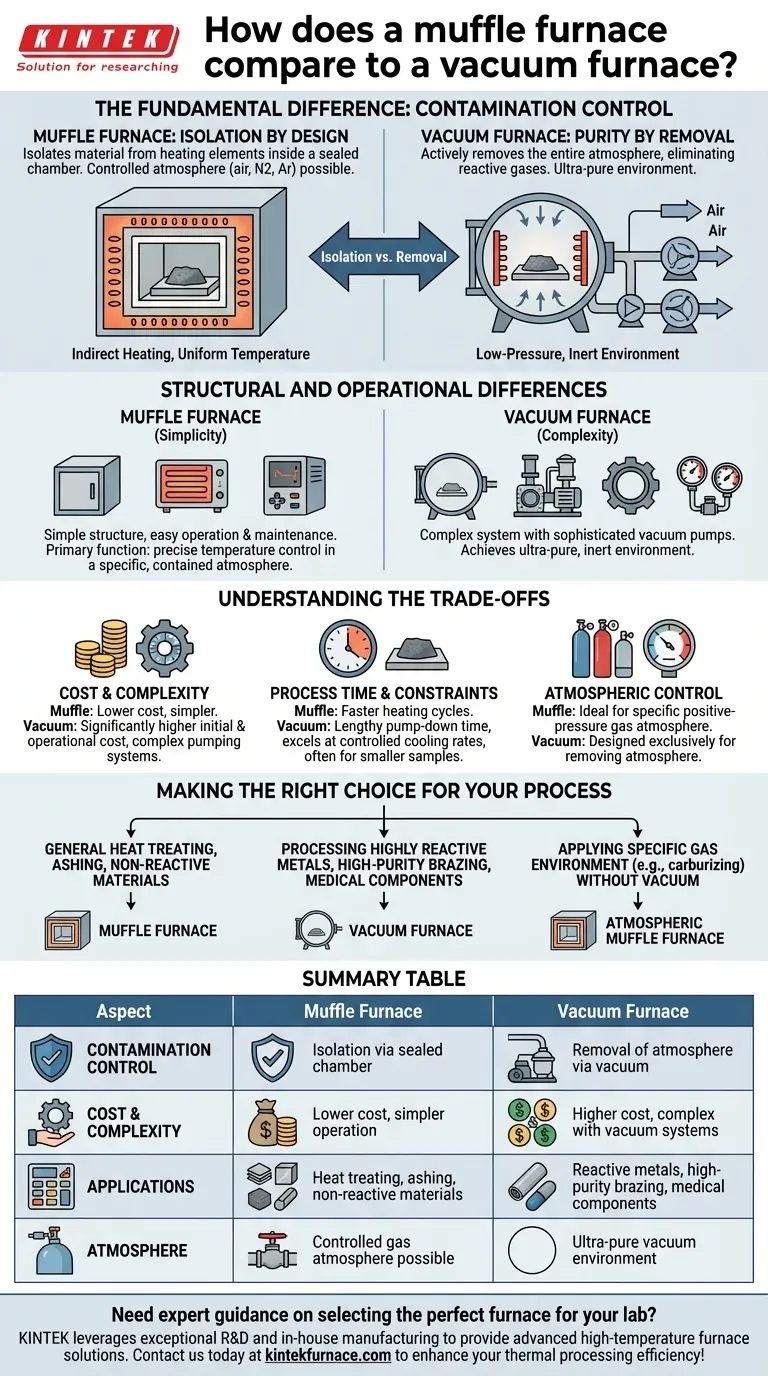

The Fundamental Difference: Contamination Control

The central purpose of both furnaces is to heat a material without unwanted chemical reactions. They simply achieve this goal in fundamentally different ways.

The Muffle Furnace: Isolation by Design

A muffle furnace uses a "box-within-a-box" design. The outer chamber contains the heating elements, while the inner, sealed chamber—the muffle—holds the material.

This indirect heating method provides two key benefits. First, it prevents the material from coming into direct contact with the heating elements or fuel source, which could cause contamination. Second, it ensures highly uniform temperature distribution around the material.

These furnaces can operate in ambient air or be purged with a specific gas (like nitrogen or argon) to create a controlled atmosphere, but they do not operate under vacuum.

The Vacuum Furnace: Purity by Removal

A vacuum furnace is engineered to create a low-pressure environment. Before the heating cycle begins, a system of powerful pumps removes virtually all air and other gases from the sealed chamber.

By removing the atmosphere, the furnace eliminates reactive elements like oxygen and nitrogen. This is critical for preventing oxidation, discoloration, and other surface reactions that would compromise the integrity of sensitive materials.

Structural and Operational Differences

The different operating principles dictate vastly different designs, complexities, and applications.

Simplicity and Atmosphere (Muffle Furnace)

A muffle furnace, often configured as a "box furnace," has a relatively simple structure. It consists of an insulated cabinet, heating elements, and a temperature controller.

Because it doesn't require a vacuum, its construction is less complex, making it easier to operate and maintain. Its primary function is precise temperature control in a specific, contained atmosphere.

Complexity and Purity (Vacuum Furnace)

A vacuum furnace is a far more complex system. It includes not only a heating chamber and controls but also a sophisticated vacuum system with multiple pumps (e.g., mechanical, diffusion), intricate seals, and pressure gauges.

This complexity is the necessary trade-off for achieving the ultra-pure, inert environment required for the most demanding applications.

Understanding the Trade-offs

Choosing the wrong furnace can be a costly mistake, either by damaging materials or by over-investing in unnecessary technology.

Cost and Complexity

A vacuum furnace represents a significantly higher investment in terms of initial cost, ongoing maintenance, and operational energy consumption due to the complex pumping systems. A muffle furnace is a more economical and straightforward solution.

Process Time and Constraints

Heating cycles in a muffle furnace are typically faster as there is no need for a lengthy "pump-down" time to create a vacuum. However, vacuum furnaces excel at controlled cooling rates, which can be critical for achieving specific material properties.

For sample size, muffle-style chambers can generally accommodate larger and bulkier samples compared to the tube furnaces often used in vacuum applications.

Atmospheric Control

This is a critical distinction. A muffle furnace is ideal when you need to introduce and maintain a specific, positive-pressure gas atmosphere. A vacuum furnace is designed exclusively for removing the atmosphere to achieve a high-purity vacuum.

Making the Right Choice for Your Process

Your decision should be based entirely on the chemical properties of your material and the desired outcome of the heat treatment.

- If your primary focus is general heat treating, ashing, or testing non-reactive materials: A muffle furnace offers the most cost-effective and direct path to precise temperature control.

- If your primary focus is processing highly reactive metals (like titanium), high-purity brazing, or medical-grade components: A vacuum furnace is non-negotiable to prevent catastrophic oxidation.

- If your primary focus is applying a specific gas environment (e.g., carburizing) without needing a vacuum: An atmospheric muffle furnace is the correct tool for the job.

By understanding the core principle of isolation versus removal, you can confidently select the right thermal processing tool for your specific material and desired outcome.

Summary Table:

| Aspect | Muffle Furnace | Vacuum Furnace |

|---|---|---|

| Contamination Control | Isolation via sealed chamber | Removal of atmosphere via vacuum |

| Cost & Complexity | Lower cost, simpler operation | Higher cost, complex with vacuum systems |

| Applications | Heat treating, ashing, non-reactive materials | Reactive metals, high-purity brazing, medical components |

| Atmosphere | Controlled gas atmosphere possible | Ultra-pure vacuum environment |

Need expert guidance on selecting the perfect furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to enhance your thermal processing efficiency and achieve superior results!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?