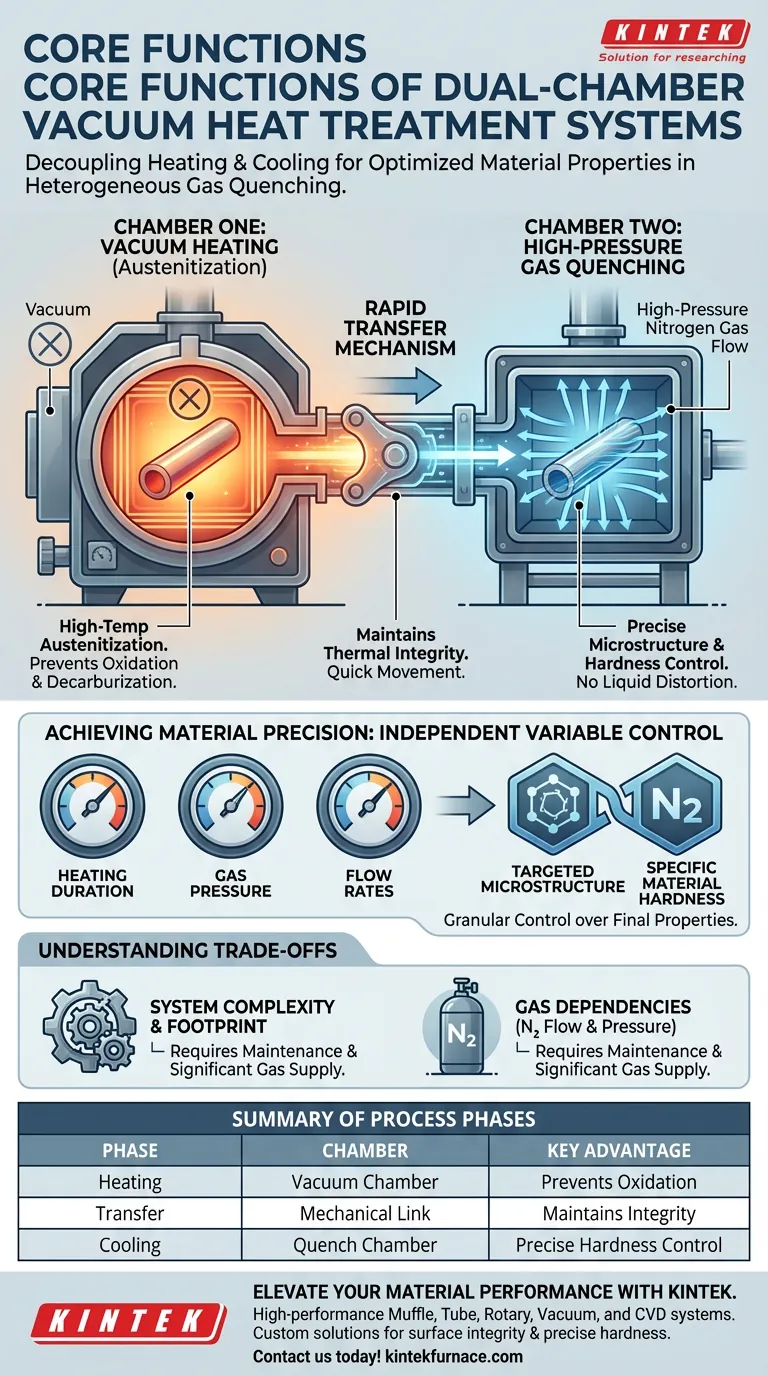

Dual-chamber vacuum heat treatment systems serve as precision integration platforms that decouple the heating and cooling phases of metallurgy to optimize material properties. These systems function by first subjecting specimens to high-temperature austenitization within a protective vacuum environment, then mechanically transferring them to a separate chamber for high-pressure nitrogen gas quenching.

Core Takeaway: The defining advantage of a dual-chamber system is the physical separation of heating and cooling environments. This design allows for oxidation-free heating followed by rapid, high-pressure cooling, granting engineers granular control over microstructure and hardness that single-environment systems often struggle to achieve.

The Mechanics of the Dual-Chamber Process

Chamber One: Protected Austenitization

The first functional stage occurs in the heating chamber. Here, the system performs high-temperature austenitization, heating the specimen to a predetermined set point.

Crucially, this occurs under vacuum protection. This environment eliminates reactive gases, preventing surface oxidation or decarburization during the critical heating phase.

The Rapid Transfer Mechanism

Once the heating cycle is complete, the system initiates a transfer sequence. The specimen is moved from the vacuum heating chamber to the quenching chamber.

Speed is vital here to maintain the temperature integrity of the part before the cooling phase begins.

Chamber Two: High-Pressure Gas Quenching

Upon entering the second chamber, the specimen undergoes rapid cooling. The system introduces high-pressure nitrogen gas to extract heat from the material.

This stage is distinct from liquid quenching; it uses gas flow to achieve the necessary cooling rates without the environmental mess or distortion risks often associated with oil or water.

Achieving Material Precision

Controlling the Critical Variables

The dual-chamber design allows for the independent management of process variables. Operators can precisely modulate heating duration, gas pressure, and flow rates.

This separation ensures that the conditions required for heating do not compromise the conditions required for cooling, and vice versa.

Targeting Microstructure and Hardness

The ultimate function of this system is to manipulate the internal structure of the metal.

By controlling the speed and pressure of the nitrogen quench, engineers can dictate the final microstructure. This directly correlates to achieving the specific material hardness required for the component's end-use application.

Understanding the Trade-offs

System Complexity and Footprint

While effective, dual-chamber systems are inherently more complex than single-chamber designs. The requirement for a mechanical transfer mechanism introduces moving parts that must be maintained to ensure consistent transfer speeds.

Gas Dependencies

The reliance on high-pressure nitrogen for quenching is a core operational consideration. Achieving the most rapid cooling rates requires significant gas flow and pressure, which becomes a primary variable in operational planning.

Making the Right Choice for Your Goal

- If your primary focus is Surface Integrity: The vacuum heating stage is your priority, as it ensures the part remains free of oxidation and requires minimal post-process cleaning.

- If your primary focus is Specific Hardness: Focus on the quenching chamber's capabilities, specifically the adjustability of gas pressure and flow rates to lock in the desired microstructure.

These systems offer the definitive solution for applications where the balance between surface quality and precise mechanical properties cannot be compromised.

Summary Table:

| Process Phase | Chamber Type | Core Function | Key Advantage |

|---|---|---|---|

| Heating | Vacuum Chamber | High-temp Austenitization | Prevents oxidation & decarburization |

| Transfer | Mechanical Link | Rapid specimen movement | Maintains thermal integrity for quench |

| Cooling | Quench Chamber | High-pressure Nitrogen Gas | Precise microstructure & hardness control |

Elevate Your Material Performance with KINTEK

Maximize the potential of your heat treatment processes with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to the rigorous demands of modern metallurgy.

Whether you require a standard dual-chamber configuration or a fully customizable high-temperature furnace for unique research needs, our engineering team ensures you achieve perfect surface integrity and precise material hardness every time.

Ready to optimize your lab's capabilities? Contact KINTEK today to discuss your specific requirements with our experts.

Visual Guide

References

- Artificial Intelligence Modeling of the Heterogeneous Gas Quenching Process for Steel Batches Based on Numerical Simulations and Experiments. DOI: 10.3390/dynamics4020023

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What other applications do vacuum furnaces have? Unlock Advanced Material Processing Across Industries

- How do high-vacuum or inert gas furnaces contribute to the precision heat treatment of nickel-based superalloys?

- How does vacuum level affect the annealing process? Optimize Material Purity and Performance

- How does an industrial microwave sintering furnace ensure uniform heating? Master Large-Scale Ceramic Processing

- What role does a vacuum system play in Vanadium-Nitrogen alloy preparation? Boost Chemical Efficiency and Yield

- In which industries is vacuum brazing commonly used? Essential for Aerospace, Medical, Automotive, and Electronics

- What operational advantages does a vacuum heat treatment furnace offer? Achieve Superior Metallurgical Quality and Precision

- What are the benefits of low pressure carburizing in terms of metal quality? Boost Fatigue Strength and Reliability