Operationally, the primary advantage of a vacuum heat treatment furnace is its ability to create a chemically inert environment. This provides an unparalleled level of control over the process, completely preventing surface reactions like oxidation and decarburization. The result is superior material purity, a bright surface finish without discoloration, and highly repeatable outcomes that are simply not possible with traditional atmosphere furnaces.

A vacuum furnace transforms heat treatment from an art into a science. By removing atmospheric variables, it guarantees that the only changes to the material are the ones you intend, leading to superior metallurgical quality, higher process yields, and a cleaner, safer operating environment.

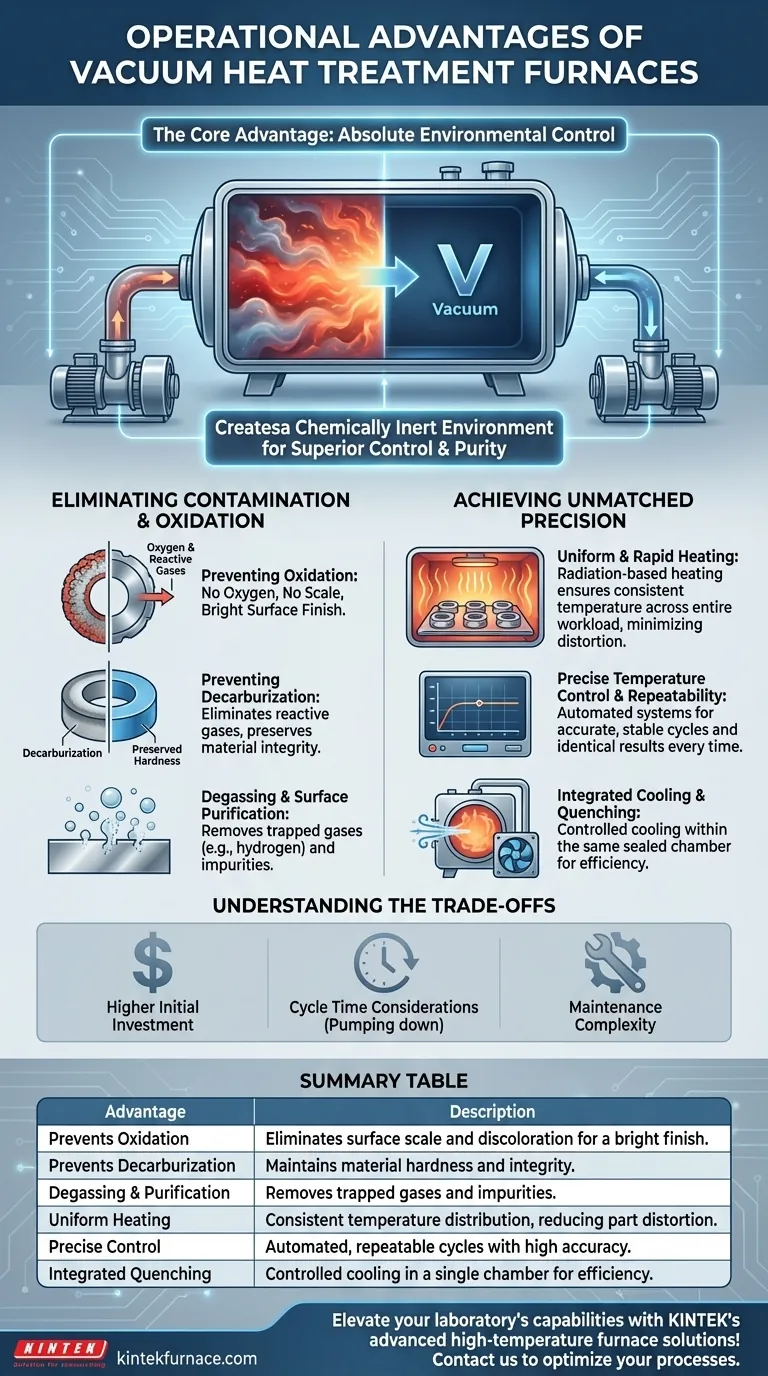

The Core Advantage: Absolute Environmental Control

The defining feature of a vacuum furnace is the removal of air and other reactive gases from the heating chamber. This fundamental difference drives most of its operational benefits.

Eliminating Oxidation and Contamination

In a conventional furnace, the oxygen present in the air reacts with the hot metal surface, creating a layer of scale or oxide. A vacuum furnace removes virtually all oxygen, preventing this oxidation entirely.

This leaves the workpiece with a clean, bright surface finish, eliminating the need for post-process cleaning or machining to remove scale. It also prevents other contaminants in the air from reacting with the part.

Preventing Decarburization

For many steels, the carbon in the alloy can react with oxygen or water vapor at high temperatures, a process called decarburization. This softens the surface layer and degrades the material's mechanical properties.

By operating in a vacuum, the reactive gases that cause decarburization are eliminated, preserving the integrity and intended hardness of the material's surface.

Degassing and Surface Purification

The vacuum environment has an added benefit: it actively pulls unwanted substances out of the material itself. This includes trapped gases like hydrogen and surface impurities like oils.

This degassing and cleaning effect results in a purer final product, which is critical for preventing issues like hydrogen embrittlement and improving the material's overall lifespan.

Achieving Unmatched Process Precision

Beyond the clean environment, vacuum furnaces offer superior control over the thermal cycle itself.

Uniform and Rapid Heating

Vacuum furnaces utilize high-efficiency heating elements that provide extremely uniform heat distribution. Because there is no air to transfer heat unevenly via convection, parts are heated primarily through radiation, ensuring consistent temperatures across the entire workload.

This leads to minimal thermal stress and part distortion, which is critical for complex geometries and tight-tolerance components.

Precise Temperature Control and Repeatability

Modern vacuum furnaces are equipped with automated, computer-controlled systems. This allows for highly accurate temperature control and stability throughout the entire heat treatment cycle.

Once a process recipe is defined, it can be executed identically every time, ensuring a high product pass rate and eliminating part-to-part variation.

Integrated Cooling and Quenching

Many vacuum furnaces are all-in-one systems that include features for rapid cooling. After the heating cycle, the chamber can be backfilled with an inert gas like nitrogen or argon to quench the material at a controlled rate.

This allows multiple processes, such as hardening and tempering, to occur within a single sealed environment, reducing handling and improving overall efficiency.

Understanding the Trade-offs

While powerful, vacuum technology is not a universal solution. It's important to recognize its specific operational context.

Higher Initial Investment

Vacuum furnaces are complex machines involving vacuum pumps, sophisticated control systems, and sealed chambers. This technology comes with a significantly higher capital cost compared to conventional atmosphere furnaces.

Cycle Time Considerations

Although heating can be rapid, the time required to pump the chamber down to the required vacuum level adds to the overall cycle time. For some low-value, high-volume parts, this may be a limiting factor compared to continuous atmosphere furnaces.

Maintenance Complexity

Maintaining a vacuum system requires specialized knowledge. Seals, pumps, and instrumentation must be kept in perfect working order to ensure the integrity of the vacuum, adding a layer of maintenance complexity.

Making the Right Choice for Your Application

Selecting the right heat treatment method depends entirely on your material, part complexity, and quality requirements.

- If your primary focus is surface finish and metallurgical purity: A vacuum furnace is the superior choice, as it completely prevents oxidation and decarburization for sensitive materials like high-chromium steel, alloys, and tool steels.

- If your primary focus is process repeatability for critical components: The precise, automated control of a vacuum furnace guarantees consistent results, reduces scrap rates, and ensures parts meet stringent specifications.

- If your primary focus is cost-reduction on simple, low-carbon parts: A traditional atmosphere furnace may be more economical if a perfect surface finish and absolute metallurgical purity are not required.

Ultimately, adopting vacuum heat treatment is a strategic decision to prioritize quality, consistency, and process control over all else.

Summary Table:

| Advantage | Description |

|---|---|

| Prevents Oxidation | Eliminates surface scale and discoloration by removing oxygen, ensuring a bright finish. |

| Prevents Decarburization | Maintains material hardness and integrity by avoiding carbon loss in steels. |

| Degassing and Purification | Removes trapped gases and impurities for a purer, longer-lasting product. |

| Uniform Heating | Uses radiation for consistent temperature distribution, reducing part distortion. |

| Precise Control | Automated systems enable repeatable cycles with high accuracy and stability. |

| Integrated Quenching | Allows controlled cooling within the same chamber, improving efficiency. |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum heat treatment furnaces that ensure superior metallurgical quality, prevent oxidation, and deliver precise, repeatable results. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs.

Contact us today to discuss how we can optimize your heat treatment processes and boost your efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing