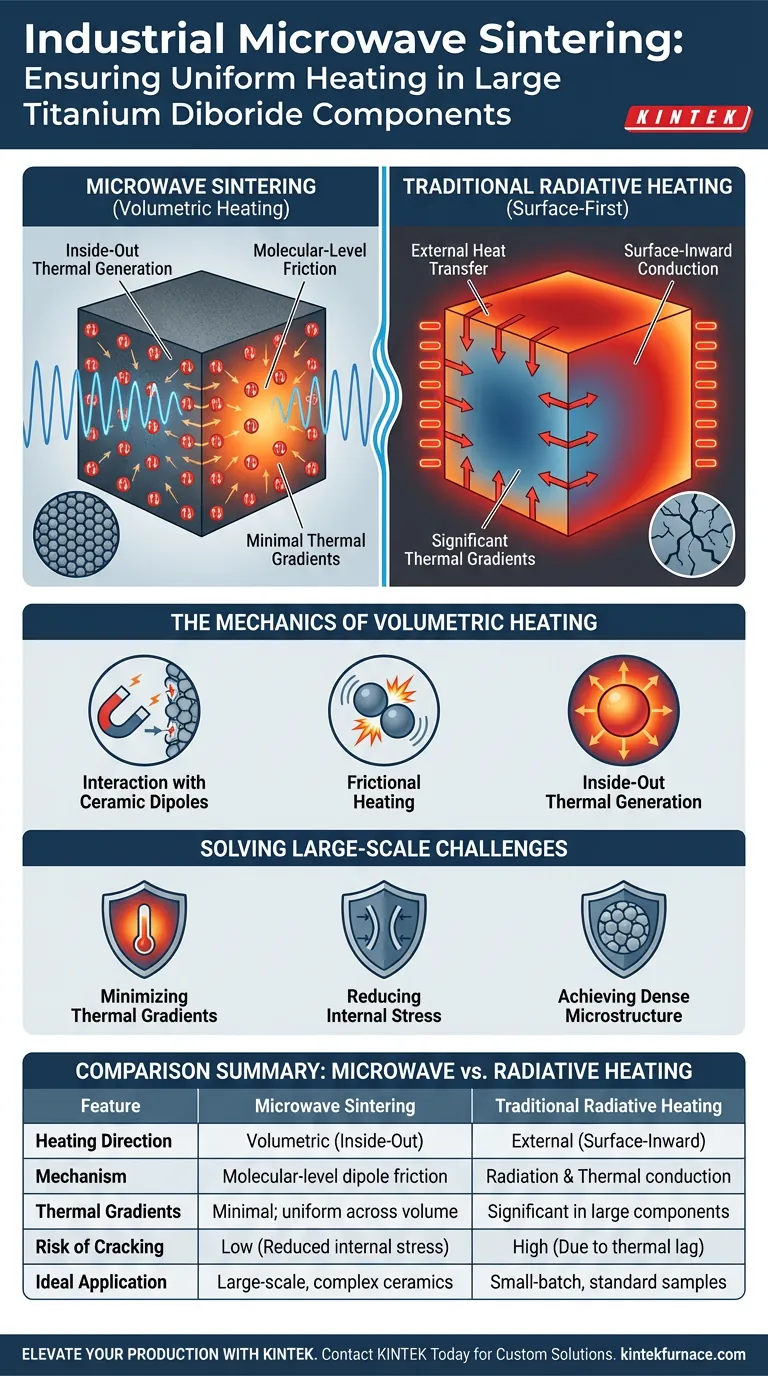

Industrial microwave sintering furnaces ensure uniformity by generating heat directly within the material itself, rather than relying on external heat sources. By exploiting the interaction between microwaves and ceramic dipoles, the system creates molecular-level friction throughout the Titanium Diboride component. This results in rapid, volumetric heating that occurs simultaneously across the entire part.

The Core Mechanism Unlike traditional methods that heat from the surface inward, microwave sintering generates heat from the inside out via molecular friction. This volumetric approach virtually eliminates the internal thermal stresses that typically cause cracking in large-scale ceramic components.

The Mechanics of Volumetric Heating

Interaction with Ceramic Dipoles

The process begins at the molecular level. Microwaves penetrate the Titanium Diboride and interact directly with ceramic dipoles within the material structure.

Frictional Heating

As these dipoles respond to the electromagnetic field, they oscillate rapidly. This movement creates molecular-level friction, which instantly converts electromagnetic energy into thermal energy.

Inside-Out Thermal Generation

Because the interaction happens throughout the volume of the material, the heat is not "transferred" but rather generated internally. This results in a heating profile that develops from the inside out, ensuring the core reaches temperature as quickly as the surface.

Solving the Large-Scale Challenge

Minimizing Thermal Gradients

In large-scale Titanium Diboride parts, maintaining consistent temperature from core to surface is the primary challenge. Microwave sintering significantly minimizes temperature gradients, preventing the uneven expansion that leads to structural failure.

Reducing Internal Stress

By ensuring the entire volume heats simultaneously, the process drastically reduces internal thermal stresses. This is critical for preventing cracking in large, complex geometries that are sensitive to thermal shock.

Achieving Dense Microstructure

The uniformity of the heating process leads to a superior final product. It facilitates a more uniform and dense microstructure, enhancing the mechanical properties of the finished ceramic component.

Comparing Heating Methodologies

The Limitations of Radiative Heating

To understand the value of microwave sintering, it is helpful to look at the alternative: tube furnaces. As noted in standard heating applications, tube furnaces rely on heating elements arranged around the exterior of a tube to provide radiative heat.

The Surface-First Constraint

While effective for smaller samples, this traditional configuration relies on external heat transfer. The heat must travel from the heating elements to the sample's surface, and then slowly conduct to the core.

The Risk for Large Components

For large-scale parts, this "outside-in" method creates a lag between surface and core temperatures. This disparity creates the very thermal gradients and stresses that microwave sintering is designed to eliminate.

Making the Right Choice for Your Goal

When selecting a sintering technology for advanced ceramics, the scale and material sensitivity dictate the best approach.

- If your primary focus is large-scale Titanium Diboride: Choose microwave sintering to leverage volumetric heating, which prevents cracking and ensures a uniform density throughout the part.

- If your primary focus is standard, small-batch processing: A traditional tube furnace may suffice, provided the sample size allows for effective radiative heat transfer without significant thermal lag.

Microwave sintering transforms the challenge of heating large ceramics by turning the material itself into the heat source, ensuring integrity where external heating fails.

Summary Table:

| Feature | Microwave Sintering | Traditional Radiative Heating |

|---|---|---|

| Heating Direction | Volumetric (Inside-Out) | External (Surface-Inward) |

| Mechanism | Molecular-level dipole friction | Radiation & Thermal conduction |

| Thermal Gradients | Minimal; uniform across volume | Significant in large components |

| Risk of Cracking | Low (Reduced internal stress) | High (Due to thermal lag) |

| Ideal Application | Large-scale, complex ceramics | Small-batch, standard samples |

Elevate Your Advanced Ceramic Production with KINTEK

Don't let thermal stress compromise your large-scale components. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you require cutting-edge microwave systems for uniform sintering or high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, our lab high-temp furnaces are fully customizable to meet your unique materials science needs.

Ready to achieve a superior, dense microstructure for your Titanium Diboride parts?

Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

References

- Xinran Lv, Gang Yu. Review on the Development of Titanium Diboride Ceramics. DOI: 10.21926/rpm.2402009

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a precision vacuum drying oven required for processing electrode sheets in LMFP slurry coating? Essential Drying

- What are the benefits of vacuum annealing on material hardness and strength? Enhance Material Integrity with Controlled Heat Treatment

- What are the different heating methods in vacuum sintering furnaces? Choose the Best for Your Materials

- What are the key benefits of using a vacuum furnace? Achieve Superior Material Purity and Control

- Why is a long-duration thermal treatment in a UHV furnace necessary for gallium intercalation? Achieve Material Purity

- What are the operational challenges associated with vacuum furnaces? Master Complexity for Superior Results

- What are the two primary configurations of vacuum furnaces? Hot Wall vs. Cold Wall Explained

- How is temperature controlled in a vacuum furnace? Achieve Precise Heat Treatment for Your Materials