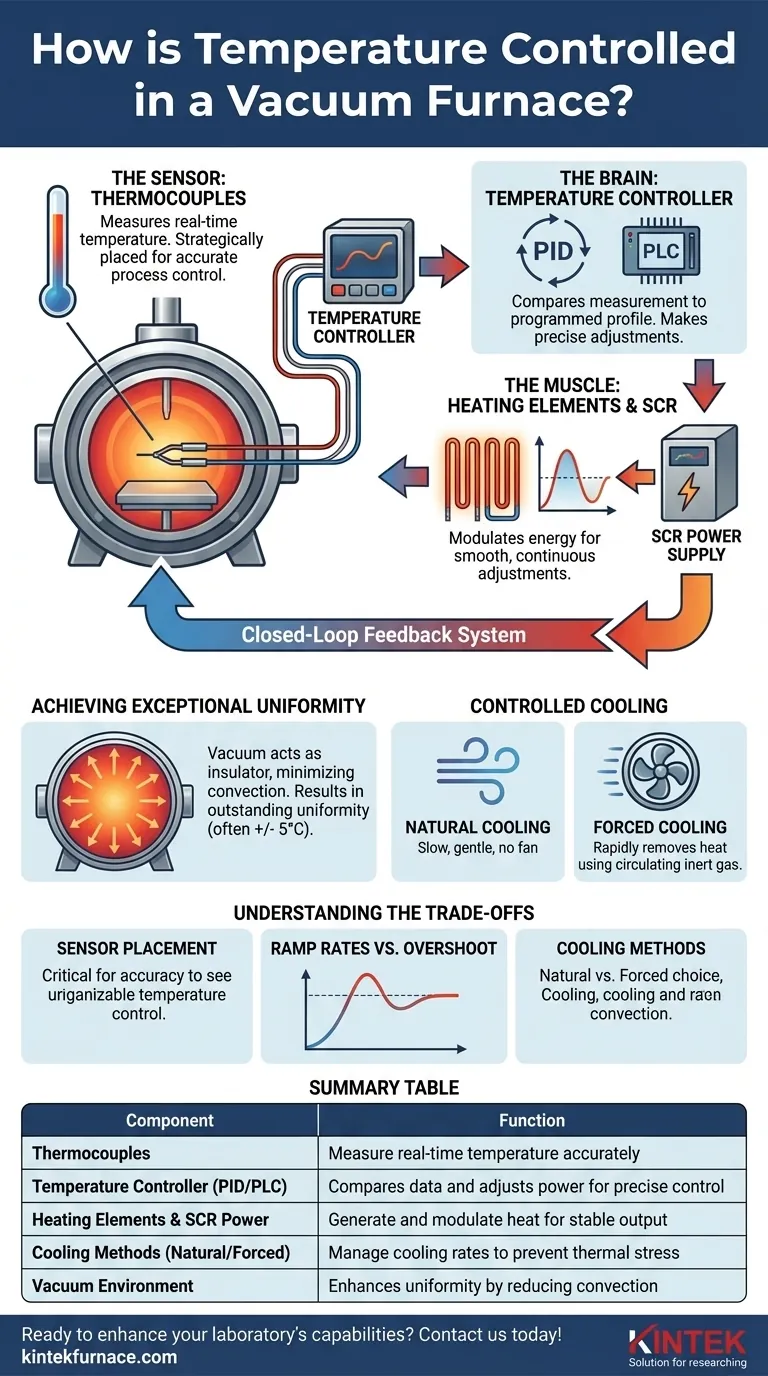

In short, temperature in a vacuum furnace is managed by a sophisticated closed-loop control system. This system uses sensors called thermocouples to measure the heat in real-time, while a central temperature controller compares this measurement to the desired temperature profile and precisely adjusts the power sent to the furnace's heating elements.

The core principle behind a vacuum furnace's exceptional temperature control is not just one component, but the synergy between three elements: highly accurate sensors, intelligent real-time power regulation, and the inherently stable thermal environment created by the vacuum itself.

The Anatomy of a Vacuum Furnace Control System

To understand how this precision is achieved, we must look at the system as a whole. It is a continuous cycle of measurement, comparison, and action that ensures the furnace follows a programmed thermal recipe with remarkable accuracy.

The Sensor: Thermocouples

A thermocouple is the system's nerve ending. It is a robust sensor that measures temperature, and its placement is critical for accurate process control.

The configuration of a vacuum furnace allows for these sensors to be strategically located throughout the heating zone and even attached directly to the workload, providing a true picture of the material's thermal state.

The Brain: The Temperature Controller

The controller is the decision-making center of the system. It receives data from the thermocouples and executes the heating and cooling plan.

Common control methods include:

- PID (Proportional-Integral-Derivative) Controllers: This is the most common type of industrial controller. It uses a mathematical feedback loop to continuously calculate the difference between the setpoint and the measured temperature, then precisely corrects for any error.

- PLC (Programmable Logic Controller): For more complex automation, a PLC can manage the entire furnace sequence, from vacuum pumping and gas backfilling to the full thermal cycle, ensuring high repeatability for production environments.

The Muscle: Heating Elements and Power Regulation

The heating elements generate the thermal energy. The controller, however, does not simply turn them on or off.

Instead, it uses a Silicon Controlled Rectifier (SCR) power supply to modulate the energy delivered to the elements. This allows for smooth, continuous adjustments, preventing the temperature swings associated with simple on/off control.

The Final Step: Controlled Cooling

Controlling temperature isn't just about heating; it's also about cooling. The system manages this in two primary ways:

- Natural Cooling: The furnace is allowed to cool slowly under vacuum. This is a gentle process ideal for minimizing thermal stress in sensitive parts.

- Forced Cooling: For faster cycle times, an inert gas like nitrogen or argon is introduced into the chamber and circulated by a fan. This rapidly removes heat from the workload in a controlled manner.

Why This System Delivers Unmatched Precision

The components alone are only part of the story. The reason a vacuum furnace provides such consistent and repeatable results lies in the principles of the system and its environment.

The Power of a Closed-Loop System

The entire process operates as a closed-loop feedback system. Think of it like a vehicle's cruise control: it constantly measures speed (temperature), compares it to the set speed (setpoint temperature), and adjusts the engine's power (heating element output) to maintain it perfectly. This real-time monitoring and adjustment ensures the thermal profile is followed exactly.

Achieving Exceptional Temperature Uniformity

A vacuum is an excellent insulator because it lacks air molecules that would otherwise transfer heat through convection. This lack of convection currents means heat is transferred primarily through radiation, which is far more uniform.

This results in outstanding temperature uniformity—often within +/- 5°C—across the entire workload. Every part, regardless of its position in the furnace, experiences virtually the same temperature.

Understanding the Trade-offs

While powerful, this technology is governed by physical and operational realities. Understanding them is key to successful processing.

The Importance of Thermocouple Placement

The system is only as accurate as its measurements. If a thermocouple is placed far from a critical area of the part, the temperature reading may not reflect the true condition of that area. Proper sensor placement is a crucial element of process design.

Ramp Rates vs. Overshoot

Aggressively fast heating cycles (high "ramp rates") can cause the temperature to exceed the target setpoint, known as overshoot. A well-tuned PID controller is essential for balancing rapid heating with the stability needed to settle precisely at the target temperature without overshooting it.

Natural vs. Forced Cooling

The choice of cooling method presents a direct trade-off. Forced cooling dramatically shortens cycle times but can introduce thermal stress in complex or delicate geometries. Natural cooling is gentle but significantly longer, impacting throughput.

Making the Right Choice for Your Goal

Understanding this system allows you to tailor its operation to your specific objective.

- If your primary focus is process repeatability (e.g., aerospace or medical production): You will rely on a PLC-automated system with a finely-tuned PID loop to ensure every cycle is identical.

- If your primary focus is materials research (e.g., developing new alloys): Your priority will be programmable controllers that allow for complex, multi-stage thermal profiles and the strategic placement of thermocouples to capture precise data.

- If your primary focus is delicate component processing (e.g., brazing): You must master the control of ramp rates and cooling methods to ensure part integrity and prevent thermal shock.

By mastering these controls, you move from simply heating a material to precisely engineering its final properties.

Summary Table:

| Component | Function |

|---|---|

| Thermocouples | Measure real-time temperature accurately |

| Temperature Controller (PID/PLC) | Compares data and adjusts power for precise control |

| Heating Elements & SCR Power | Generate and modulate heat for stable output |

| Cooling Methods (Natural/Forced) | Manage cooling rates to prevent thermal stress |

| Vacuum Environment | Enhances uniformity by reducing convection |

Ready to enhance your laboratory's capabilities with precise temperature control? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering unmatched repeatability and efficiency. Contact us today to discuss how our tailored solutions can benefit your aerospace, medical, or materials research applications!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance