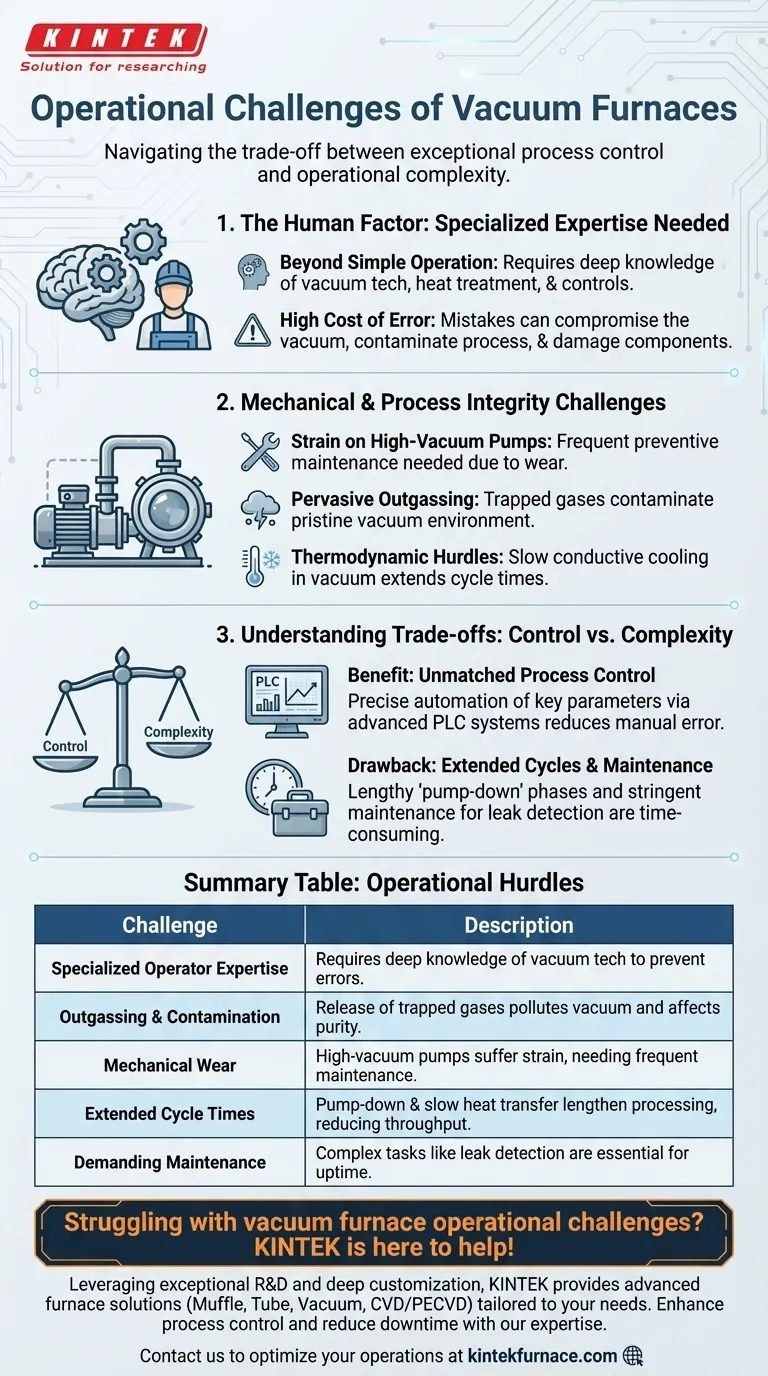

Operating a vacuum furnace involves a distinct set of challenges that go far beyond those of standard atmospheric furnaces. The primary operational hurdles include the need for highly specialized operator knowledge, the constant threat of process contamination from outgassing, mechanical wear on vacuum components, and significantly longer process cycle times due to the need to achieve and maintain a vacuum.

The exceptional process control and purity offered by a vacuum furnace are a direct trade-off for higher operational complexity. Success depends on accepting and managing the demands of specialized maintenance, operator expertise, and longer processing cycles.

The Human Factor: The Need for Specialized Expertise

The most significant operational variable is often the human one. Unlike simpler equipment, a vacuum furnace cannot be run effectively without a deep understanding of its underlying principles.

Beyond Simple Operation

Operators must be more than technicians; they need to be specialists. A comprehensive knowledge of vacuum technology, specific heat treatment processes, and the furnace's electrical control system is non-negotiable.

The High Cost of Error

Without professional training, operator errors can easily compromise the vacuum, contaminate the process, and damage sensitive components. This directly impacts both equipment performance and the quality of the final product.

Mechanical and Process Integrity Challenges

The vacuum environment itself creates unique mechanical and physical challenges that demand constant attention.

The Strain on High-Vacuum Pumps

High-vacuum pumps are precision instruments subject to significant wear and tear. Sustaining a deep vacuum for extended periods places immense strain on these components, necessitating a rigorous preventive maintenance schedule.

The Pervasive Problem of Outgassing

Outgassing—the release of trapped gases from the chamber walls or the workpiece itself—is a constant threat. This phenomenon can contaminate the pristine vacuum environment, leave unwanted residue on treated parts, and compromise the integrity of the process.

Thermodynamic Hurdles

In a vacuum, heat transfer via convection is virtually eliminated. This makes cooling a significant challenge, as it must rely on slower conductive methods or specialized gas quenching systems. This limitation directly impacts cycle times and process design.

Unpredictable Material Behavior

Certain materials can behave unexpectedly under vacuum conditions at high temperatures. This requires careful process development and validation to ensure desired outcomes and avoid damaging the material or the furnace.

Understanding the Trade-offs: Control vs. Complexity

The decision to use a vacuum furnace is a classic engineering trade-off. You gain unparalleled control at the cost of operational simplicity.

The Benefit: Unmatched Process Control

The primary advantage is strong, repeatable control over every key parameter. Advanced PLC control systems and digital monitoring allow for precise automation of heating temperature, vacuum level, and insulation time, dramatically reducing the potential for manual error.

The Drawback: Extended Cycle Times

Achieving a deep vacuum is not instantaneous. The initial "pump-down" phase can be lengthy, significantly extending the total cycle time compared to an atmospheric furnace. This is a critical consideration for production throughput.

The Drawback: Demanding Maintenance

The stringent requirements for vacuum integrity make maintenance far more complex. Detecting and repairing minuscule leaks, servicing sensitive pumps, and ensuring internal cleanliness are critical and time-consuming tasks.

Advanced Solutions and Their Implications

Modern furnace designs incorporate features to mitigate some of these operational challenges, especially for high-throughput applications.

Automation with PLC Systems

Modern PLC (Programmable Logic Controller) systems provide comprehensive automation, monitoring, and built-in safety protections. This enhances reliability and eases the operational burden, though it does not eliminate the need for expert oversight.

Multi-Chamber Systems for Throughput

For continuous processing, multiple-chamber furnaces offer a solution to the pump-down bottleneck. By keeping loading, heating, and quenching zones under a constant vacuum, they enable a much more efficient workflow by processing batches simultaneously.

Making the Right Choice for Your Operation

To determine if a vacuum furnace is appropriate, you must align its capabilities with your primary operational goal.

- If your primary focus is ultimate process purity and control: The operational complexity is a necessary cost for achieving superior, highly repeatable material properties.

- If your primary focus is high-volume throughput: A single-chamber furnace's long cycle times will be a major bottleneck; investigate multi-chamber systems to improve workflow.

- If your primary focus is minimizing operational overhead: Be prepared for significant investment in both rigorous operator training and a diligent preventive maintenance schedule to avoid costly downtime.

Ultimately, mastering a vacuum furnace requires balancing its powerful capabilities with the operational discipline required to maintain its demanding environment.

Summary Table:

| Challenge | Description |

|---|---|

| Specialized Operator Expertise | Requires deep knowledge of vacuum tech, heat treatment, and control systems to prevent errors and contamination. |

| Outgassing and Contamination | Release of trapped gases can pollute the vacuum, affecting process purity and part quality. |

| Mechanical Wear | High-vacuum pumps and components suffer from strain, needing frequent preventive maintenance. |

| Extended Cycle Times | Pump-down phases and slow heat transfer in vacuum lengthen processing, reducing throughput. |

| Demanding Maintenance | Complex tasks like leak detection and pump servicing are essential for vacuum integrity and uptime. |

Struggling with vacuum furnace operational challenges? KINTEK is here to help! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is supported by strong deep customization capabilities to precisely meet your unique experimental needs. Enhance your process control, reduce downtime, and achieve superior results with our expertise. Contact us today to discuss how we can optimize your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures