A precision vacuum drying oven is indispensable for processing LMFP (Lithium Manganese Iron Phosphate) electrode sheets to ensure the complete elimination of solvents and residual moisture. Specifically, this process involves baking the slurry-coated aluminum foil at 120°C for extended periods to remove N-Methyl-2-pyrrolidone (NMP) and deeply embedded water molecules.

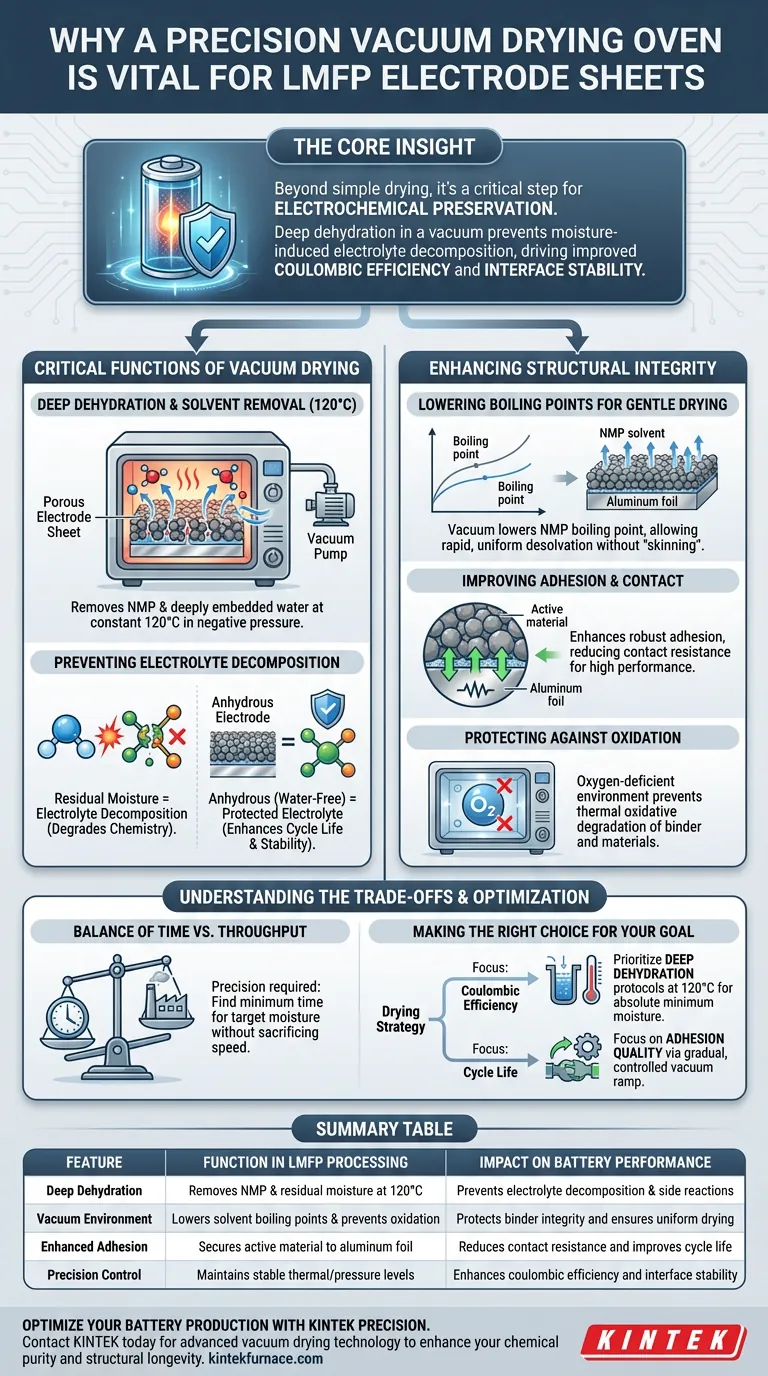

The Core Insight: The necessity of this equipment extends beyond simple drying; it is a critical step for electrochemical preservation. Deep dehydration in a vacuum environment prevents moisture-induced electrolyte decomposition, which is the primary driver for improved coulombic efficiency and interface stability in the final battery cell.

Critical Functions of Vacuum Drying for LMFP

Deep Dehydration and Solvent Removal

The primary challenge in LMFP electrode processing is the presence of NMP solvent and trace moisture. Standard thermal drying is often insufficient to remove these components from the porous structure of the electrode.

A precision vacuum oven operates at a constant 120°C, providing the thermal energy required to drive out these volatiles. Simultaneously, the negative pressure environment facilitates "deep dehydration," extracting moisture that is physically adsorbed into the active materials and binders.

preventing Electrolyte Decomposition

Residual moisture is a silent killer of battery performance. If water remains in the electrode sheet, it reacts with the electrolyte once the battery is assembled.

This reaction leads to electrolyte decomposition, which degrades the battery's internal chemistry. By ensuring the electrode is anhydrous (water-free), the vacuum drying process protects the electrolyte, thereby enhancing the battery's cycle life and stability.

Enhancing Structural Integrity

Lowering Boiling Points for Gentle Drying

The vacuum environment significantly lowers the boiling point of organic solvents like NMP. This allows for rapid desolvation without requiring excessive temperatures that might damage the electrode components.

By drying at a lower effective pressure, the solvent evaporates more easily from the internal structure. This prevents the "skinning" effect—where the surface dries too fast and traps solvent inside—ensuring a uniform internal structure.

Improving Adhesion and Contact

The drying process directly impacts how well the active material sticks to the current collector.

The vacuum treatment enhances the adhesion between the LMFP active material and the aluminum foil. This robust mechanical and electrical contact reduces contact resistance, which is vital for maintaining high performance during charge and discharge cycles.

Protecting Against Oxidation

While drying, materials are vulnerable to reaction with oxygen in the air. A vacuum oven creates an oxygen-deficient environment.

This prevents thermal oxidative degradation of the binder and active materials. Protecting these components during the heating phase preserves their chemical composition, ensuring reaction consistency and structural stability.

Understanding the Trade-offs

The Balance of Time vs. Throughput

Vacuum drying is inherently a batch process that requires extended periods to be effective.

Attempting to rush this process by increasing the temperature beyond 120°C or reducing the vacuum time can lead to incomplete drying. Conversely, excessively long drying times create bottlenecks in manufacturing throughput. Precision is required to find the minimum time necessary to achieve the target moisture content without sacrificing production speed.

Making the Right Choice for Your Goal

To maximize the potential of your LMFP electrodes, align your drying strategy with your specific performance targets:

- If your primary focus is Coulombic Efficiency: Prioritize deep dehydration protocols at 120°C to ensure absolute minimum moisture content, preventing electrolyte side reactions.

- If your primary focus is Cycle Life: Focus on the adhesion quality by ensuring a gradual, controlled vacuum ramp that prevents coating delamination or cracking.

The precision vacuum drying oven is not merely a dryer; it is the gatekeeper of your battery's chemical purity and structural longevity.

Summary Table:

| Feature | Function in LMFP Processing | Impact on Battery Performance |

|---|---|---|

| Deep Dehydration | Removes NMP and residual moisture at 120°C | Prevents electrolyte decomposition & side reactions |

| Vacuum Environment | Lowers solvent boiling points & prevents oxidation | Protects binder integrity and ensures uniform drying |

| Enhanced Adhesion | Secures active material to aluminum foil | Reduces contact resistance and improves cycle life |

| Precision Control | Maintains stable thermal/pressure levels | Enhances coulombic efficiency and interface stability |

Optimize Your Battery Production with KINTEK Precision

Don't let residual moisture compromise your LMFP battery performance. KINTEK provides industry-leading thermal solutions, including customizable Vacuum, Muffle, and Tube furnaces, specifically designed for high-precision laboratory and manufacturing needs.

Backed by expert R&D and manufacturing, our systems ensure superior dehydration and adhesion for your electrode sheets. Contact KINTEK today to discover how our advanced vacuum drying technology can enhance your chemical purity and structural longevity.

Visual Guide

References

- Shaojun Liu, Chengguo Sun. Freeze-Drying-Assisted Preparation of High-Compaction-Density LiMn0.69Co0.01Fe0.3PO4 Cathode Materials with High-Capacity and Long Life-Cycle for Lithium Ion Batteries. DOI: 10.3390/batteries10040114

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a vacuum dryer play in the chemical modification of supraparticles? Master Vapor-Phase Hydrophobization

- What is the significance of the thermal hysteresis temperature difference (Xth) in vacuum sintering? Control Heat Lag

- How do chillers improve product quality in heat treatment? Achieve Precise, Repeatable Cooling for Superior Results

- What is vacuum brazing used for? Achieve Clean, Strong, and Distortion-Free Joints

- How are vacuum furnaces utilized in additive manufacturing post-processing? Unlock High-Performance Metal Parts

- How does a vertical vacuum furnace separate magnesium, zinc, and aluminum? Exploit Boiling Points for Metal Recovery

- What is the role of vacuum furnaces in medical device manufacturing? Ensure Purity and Safety for Implants

- What types of vacuum brazing furnaces are available? Choose the Right Design for Your Materials