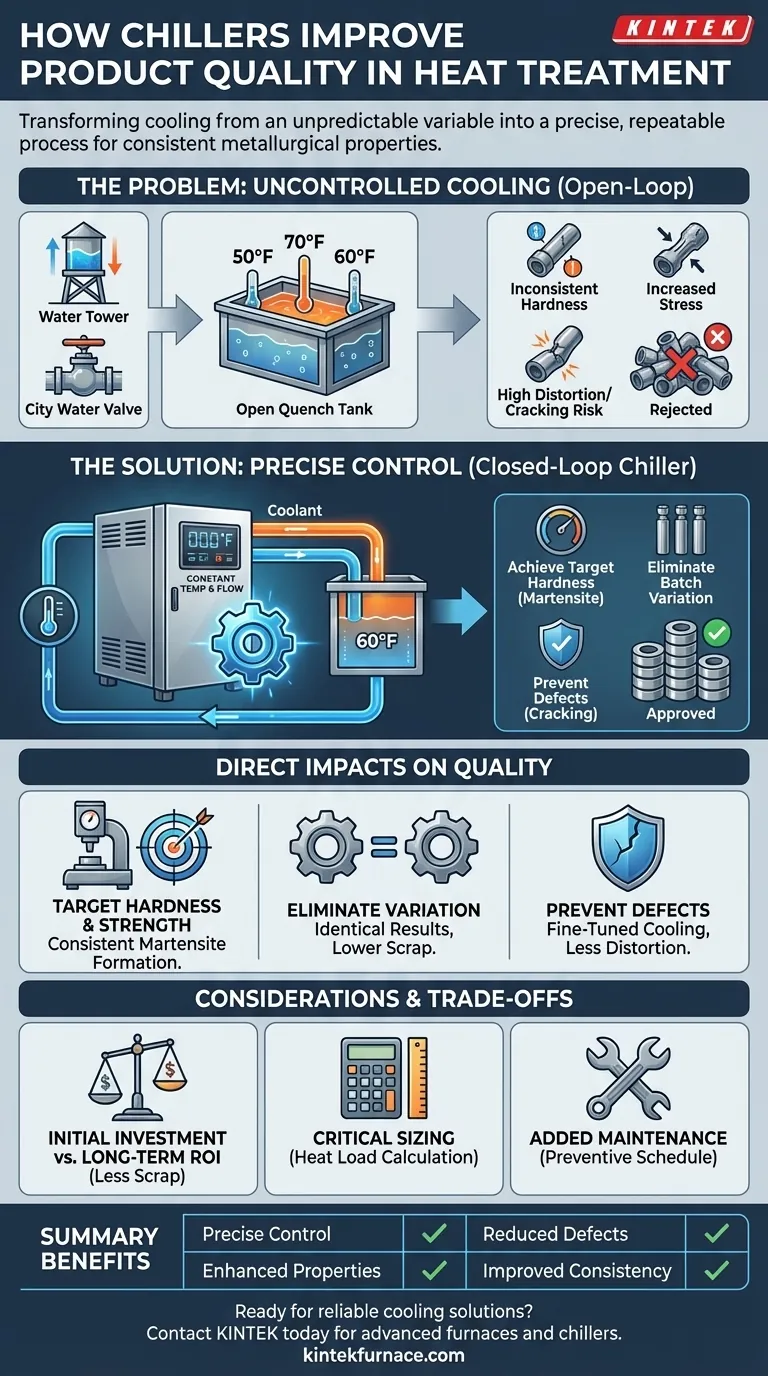

At its core, a chiller improves product quality in heat treatment by transforming cooling from an unpredictable variable into a precise, repeatable process. While the heating cycle gets much of the attention, the rate and consistency of cooling—the quench—are what ultimately lock in the desired metallurgical properties of the material. By delivering a cooling medium at a constant temperature and flow rate, a chiller eliminates the guesswork and ensures every part achieves its specified hardness, strength, and structural integrity.

The fundamental value of a chiller in heat treatment is not merely making things cold; it is about providing absolute control over the rate of cooling. This control directly dictates the final microstructure of the metal, guaranteeing consistent, predictable, and high-quality results from one batch to the next.

The Critical Role of Cooling in Heat Treatment

To understand the impact of a chiller, you must first understand the science of the quench. Heat treatment is a process of controlled heating and cooling to alter a material's physical and mechanical properties.

The Science of the Quench

During heating, a metal's crystalline structure changes. For steel, it transforms into a phase called austenite. The goal of quenching is to cool the metal so rapidly that the atoms do not have time to revert to their softer, pre-heated state.

This rapid cooling "traps" a very hard, strong, and brittle crystal structure known as martensite. The speed of the quench is the single most important factor in determining how much of the material successfully transforms into this desirable structure.

The Problem with Uncontrolled Cooling

Many operations use city water or open-loop cooling towers for quenching. This introduces significant variability. The water temperature can fluctuate based on the season, time of day, or other plant operations.

This inconsistency means the quench rate is never the same. One batch may be quenched with 50°F water, and the next with 70°F water. This leads directly to inconsistent hardness, increased internal stresses, and a higher risk of part distortion or cracking.

How Chillers Provide Absolute Control

A process chiller solves this problem by creating a closed loop of coolant (typically water or a water-glycol mix) that is maintained at a precise temperature, regardless of ambient conditions.

The chiller guarantees that every time a part is quenched, the cooling medium is at the exact same temperature and is delivered at the same flow rate. The quench becomes a defined engineering parameter, not a source of random variation.

Direct Impacts on Product Quality

Translating process control into product quality is where a chiller demonstrates its return on investment. The improvements are measurable and significant.

Achieving Target Hardness and Strength

By ensuring an optimal and repeatable quench rate, a chiller allows you to consistently achieve the target martensitic structure. This means every part meets its specified Rockwell hardness, tensile strength, and wear resistance.

Eliminating Batch-to-Batch Variation

For any production environment, consistency is paramount. A chiller ensures the thousandth part is identical to the first. This reduces the need for extensive quality inspection, lowers scrap rates, and builds customer confidence in your product.

Preventing Defects, Distortion, and Cracking

While a fast quench is necessary, a quench that is too aggressive or uneven can cause thermal shock, leading to micro-cracks or visible part distortion.

A chiller allows you to fine-tune the cooling rate. You can select the ideal coolant temperature that is fast enough to form martensite but gentle enough to prevent damage, a crucial balance for complex or delicate geometries. This is especially important in processes like vacuum heat treating, where a clean surface finish must be preserved.

Understanding the Trade-offs and Pitfalls

While highly effective, integrating a chiller requires careful consideration. Objectivity demands acknowledging the potential challenges.

Initial Investment vs. Long-Term ROI

A process chiller is a significant capital expense. This cost must be weighed against the financial impact of inconsistent quality, including rejected parts, scrap material, customer claims, and damage to your brand's reputation.

System Sizing is Critical

One of the most common pitfalls is improper sizing. An undersized chiller will not be able to remove heat fast enough, causing the coolant temperature to rise and negating the entire purpose of the investment. An oversized chiller will short-cycle and operate inefficiently, wasting energy.

A proper heat load calculation by a qualified engineer is non-negotiable to ensure the chiller matches the demands of your specific heat treatment process.

Added Maintenance and Complexity

A chiller is another piece of industrial equipment that requires a preventive maintenance schedule. This includes checking refrigerant levels, cleaning coils, and ensuring pump integrity. It adds a layer of complexity compared to simply opening a valve for city water.

Making the Right Choice for Your Process

Deciding to integrate a chiller should be based on your specific quality and production goals.

- If your primary focus is high-volume production with tight tolerances: A dedicated process chiller is non-negotiable for achieving the required repeatability and minimizing scrap.

- If your primary focus is producing high-value, complex parts: The precise control from a chiller is essential for preventing distortion and cracks that would result in a total loss.

- If you are experiencing inconsistent quality or high rejection rates: Analyzing your current cooling method is the first step; a chiller is often the most direct solution to eliminate temperature variables.

By mastering the cooling cycle, you gain direct command over the final quality and performance of your product.

Summary Table:

| Key Benefit | Description |

|---|---|

| Precise Cooling Control | Maintains constant temperature and flow rate for repeatable quench cycles. |

| Enhanced Metallurgical Properties | Achieves target hardness and strength by forming martensite consistently. |

| Reduced Defects | Minimizes distortion, cracking, and batch-to-batch variation. |

| Improved Consistency | Ensures identical results across all parts, lowering scrap rates. |

Ready to elevate your heat treatment process with reliable cooling solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to discuss how our chillers and furnaces can enhance your product quality and efficiency!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment