At its core, vacuum brazing furnaces are primarily categorized by their heating chamber design and their loading orientation. While many variations exist, the fundamental types are hot wall and cold wall furnaces, which can be configured as either horizontal or vertical loading systems to suit different parts and processes.

The choice of a vacuum brazing furnace is not about finding the "best" type, but about aligning the furnace's fundamental design—its heating method and part orientation—with the specific material requirements, part geometry, and temperature profile of your application.

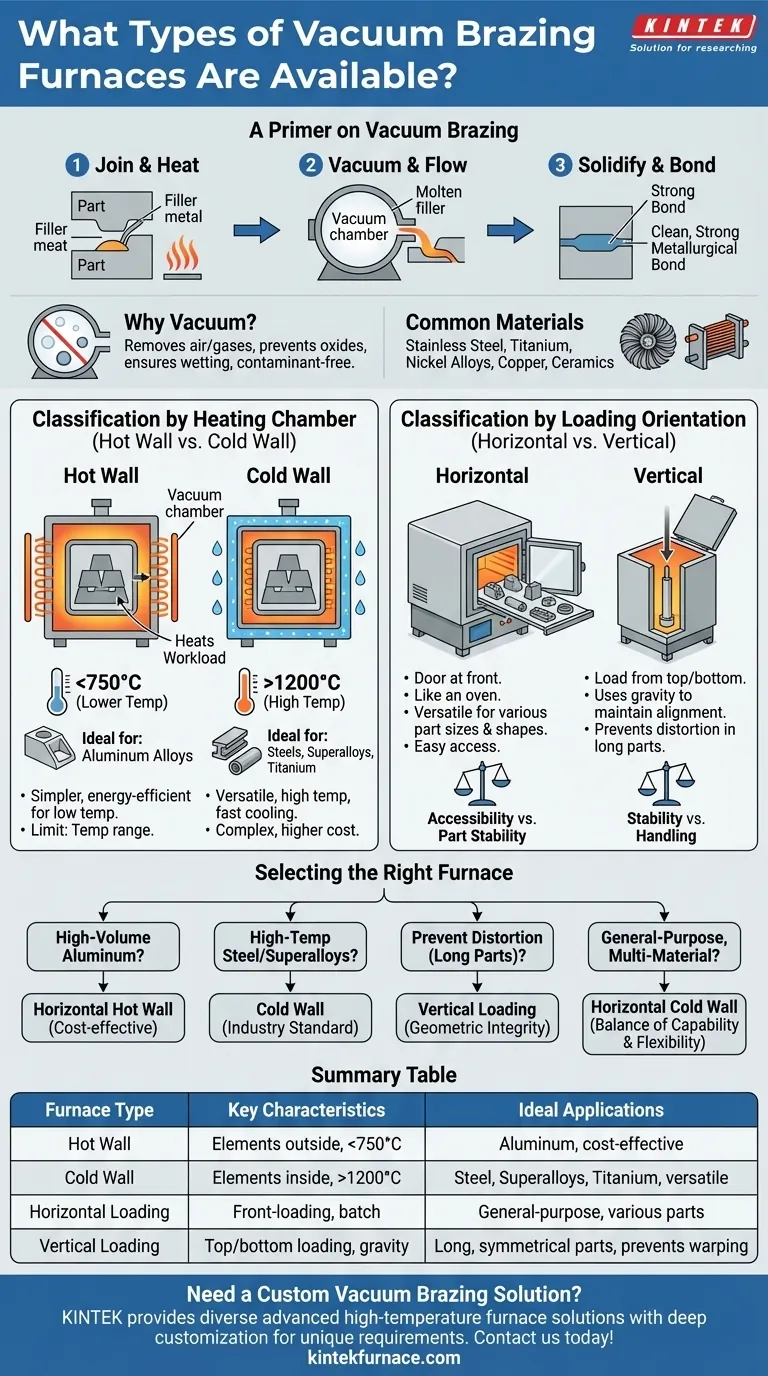

First, A Primer on the Vacuum Brazing Process

To understand the differences in furnace design, it's essential to first grasp the process they are built to perform.

What is Vacuum Brazing?

Vacuum brazing is a high-integrity joining technique that connects two or more components. A filler metal, with a melting point lower than the base materials, is placed at the joint.

The assembly is heated in the furnace until the filler metal melts and flows into the gap between the parts through capillary action. Upon cooling, the filler solidifies, creating an exceptionally strong and clean metallurgical bond without melting the components themselves.

Why Use a Vacuum?

The key to the process is the vacuum environment. By removing air and other gases, the furnace prevents the formation of oxides on the metal surfaces during the high-temperature cycle.

This ensures the filler metal can properly wet the surfaces, resulting in a joint that is free from contamination and internal voids, which is critical for leak-tight and high-strength applications.

Common Materials and Applications

This process is ideal for joining difficult-to-weld or dissimilar materials, such as stainless steel, titanium, nickel alloys, copper, and even ceramics.

Its precision and reliability make it essential in demanding industries. It is heavily used for aerospace components like turbine blades, automotive heat exchangers, and fuel and hydraulic system components where joint failure is not an option.

The Two Primary Ways to Classify Furnaces

While custom designs exist, nearly all industrial vacuum brazing furnaces fall into two key classification sets. The first is how they generate heat, and the second is how you load parts into them.

Classification by Heating Chamber: Hot Wall vs. Cold Wall

This is the most critical technical distinction, as it dictates the furnace's operating temperature range and suitability for different materials.

-

Hot Wall Furnaces In a hot wall design, the heating elements are located outside a sealed vacuum chamber, or "retort." The entire retort is heated, which in turn heats the workload inside. These are generally used for lower-temperature processes (typically under ~750°C), such as the brazing of aluminum alloys.

-

Cold Wall Furnaces This is the more common design for high-temperature brazing. The heating elements are located inside the vacuum chamber, surrounding the workload directly. The outer vessel wall is water-cooled, keeping it cool to the touch. This design allows for much higher temperatures (often exceeding 1200°C) and faster cooling rates, making it the standard for brazing steels, superalloys, and titanium.

Classification by Loading Orientation: Horizontal vs. Vertical

This classification is more straightforward and relates to the physical handling of the parts.

-

Horizontal Furnaces These are the most common type, operating like a conventional oven with a door at the front. Parts are loaded onto trays or fixtures and pushed into the chamber. This design is highly versatile and accommodates a wide range of part sizes and shapes.

-

Vertical Furnaces In a vertical furnace, parts are loaded from the top or bottom. This orientation is preferred for parts that are long, symmetrical, or prone to distortion. Loading vertically uses gravity to maintain the part's alignment and prevent sagging or warping at high temperatures.

Understanding the Critical Trade-offs

Choosing a furnace involves balancing capability, cost, and process requirements. Each design comes with inherent compromises.

Hot Wall: Simplicity vs. Temperature Limits

Hot wall furnaces have a simpler design and are often more energy-efficient for their target temperature range. However, their materials of construction limit their maximum operating temperature, making them unsuitable for high-temperature alloys.

Cold Wall: Versatility vs. Complexity

Cold wall furnaces are the workhorses of the industry, capable of handling nearly any brazing application from mid-range to very high temperatures. This versatility comes with increased complexity, including sophisticated water-cooling systems and internal power feedthroughs, making them more expensive to build and maintain.

Horizontal vs. Vertical: Accessibility vs. Part Stability

Horizontal furnaces offer easy access for loading and unloading and are well-suited for batch processing of various parts. However, for specific geometries, the need to prevent distortion makes a vertical furnace the only viable choice, even if it requires more complex material handling and facility overhead.

Selecting the Right Furnace for Your Application

Your final decision should be driven entirely by your specific process goals.

- If your primary focus is high-volume aluminum brazing: A horizontal hot wall furnace often provides the most cost-effective and thermally uniform environment for this specific task.

- If your primary focus is high-temperature brazing of steels or superalloys: A cold wall furnace is the industry standard, offering the necessary temperature range and rapid cooling control.

- If your primary focus is preventing distortion in long or circular parts: A vertical loading furnace is the superior choice to maintain geometric integrity during the thermal cycle.

- If your primary focus is general-purpose, multi-material brazing: A horizontal cold wall furnace offers the greatest balance of capability and flexibility for a contract brazing or R&D environment.

Understanding these core design principles allows you to move beyond a simple list of models and select a furnace based on the fundamental needs of your process.

Summary Table:

| Furnace Type | Key Characteristics | Ideal Applications |

|---|---|---|

| Hot Wall | Heating elements outside vacuum chamber; lower temperatures (<750°C) | Aluminum alloy brazing, cost-effective for specific tasks |

| Cold Wall | Heating elements inside vacuum chamber; higher temperatures (>1200°C) | Steel, superalloy, titanium brazing; versatile for high-integrity joints |

| Horizontal Loading | Front-loading design; easy access and batch processing | General-purpose brazing, various part sizes and shapes |

| Vertical Loading | Top or bottom loading; uses gravity to prevent distortion | Long, symmetrical parts prone to warping, such as aerospace components |

Need a Custom Vacuum Brazing Solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for materials like stainless steel, titanium, and more. Contact us today to enhance your brazing process with tailored, reliable equipment!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures