At its core, vacuum brazing is used to create exceptionally clean, strong, and distortion-free joints in high-performance components where failure is not an option. This advanced manufacturing technique is the go-to solution for industries like aerospace, medical devices, and automotive, as it allows for the joining of complex assemblies and sensitive materials that cannot be reliably joined by other methods.

While many processes can join metals, vacuum brazing is the definitive choice when the absolute integrity of the final assembly is non-negotiable. It solves the fundamental problems of oxidation and thermal stress that plague other methods, making it essential for mission-critical applications.

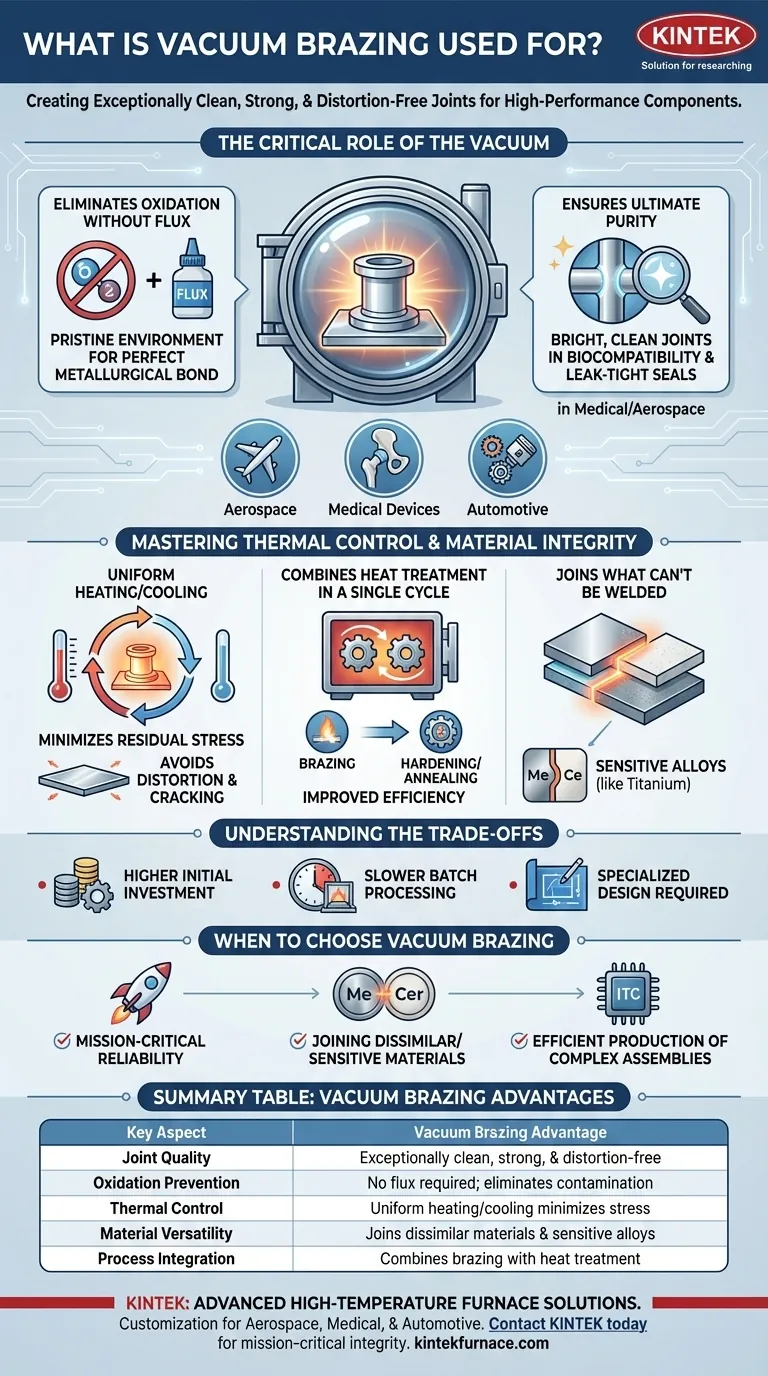

Why a Vacuum is the Critical Ingredient

The "vacuum" in vacuum brazing is not a minor detail; it is the central element that enables its unique benefits. By removing the atmosphere from a sealed furnace, the process fundamentally changes how metals can be joined.

Eliminating Oxidation Without Flux

In a normal atmosphere, heating metal causes it to form an oxide layer on its surface. This layer acts as a barrier, preventing the filler metal from properly wetting the base materials and creating a weak, unreliable bond.

Traditional brazing solves this with a chemical agent called flux, but flux can become trapped in the joint, leading to corrosion and potential failure points.

Vacuum brazing eliminates the need for flux entirely. By removing the oxygen, it creates a pristine environment where no oxides can form, allowing the molten filler metal to create a perfect, direct metallurgical bond with the parent materials.

Ensuring Ultimate Purity

The result of this flux-less, oxide-free process is a bright, shiny, and exceptionally clean joint. This isn't merely aesthetic; it is a visual confirmation of the bond's purity.

For medical implants and surgical tools, this cleanliness is essential for biocompatibility and sterilization. In aerospace and hydraulic systems, it ensures a leak-tight seal with no hidden contaminants that could cause failure down the line.

Mastering Thermal Control and Material Integrity

Beyond cleanliness, vacuum brazing provides an unparalleled level of control over the thermal cycle. This precision is key to maintaining the strength and dimensional accuracy of the final product.

Minimizing Residual Stress

A vacuum furnace allows for very slow, uniform heating and cooling of the entire assembly. This gradual process minimizes thermal shock and residual stress that can cause distortion, warping, or cracking in the base materials.

Because the entire part is heated evenly, complex assemblies maintain their precise dimensions, a critical factor for components like turbine blades or intricate heat exchangers.

Combining Heat Treatment in a Single Cycle

Many high-strength alloys require heat treatment processes like hardening, annealing, or aging to achieve their desired mechanical properties.

A significant advantage of vacuum brazing is the ability to combine these treatments into a single furnace cycle. The assembly can be brazed and then brought to a different temperature for heat treatment, all within the same controlled environment. This drastically improves efficiency and reduces costs, especially in high-volume production.

Joining What Can't Be Welded

Welding relies on melting the base metals, which can alter or damage the metallurgy of sensitive materials like titanium, high-temperature superalloys, and certain stainless steels.

Vacuum brazing operates below the melting point of the base metals, leaving their properties intact. This makes it the ideal method for joining these difficult-to-weld alloys and for creating assemblies from dissimilar materials, such as metal to ceramic.

Understanding the Trade-offs

No process is without its limitations. Objectivity requires acknowledging where vacuum brazing might not be the best fit.

Higher Initial Investment

Vacuum furnaces are sophisticated pieces of capital equipment that represent a significant financial investment. The cost and complexity of the machinery make it unsuitable for small shops or low-volume prototyping where cost is the primary driver.

Slower Batch Processing

The controlled heating and cooling cycles, while a key benefit for quality, are inherently slow. Vacuum brazing is a batch process, meaning parts must be loaded, the furnace sealed and pumped down, run through its cycle, and cooled before being unloaded. This results in longer cycle times compared to continuous processes or manual welding.

Requirement for Specialized Design

Parts must be specifically designed for vacuum brazing. This includes engineering the correct joint clearance to allow for capillary action of the filler metal and designing fixtures that will hold the assembly in place without interfering with the process or distorting at high temperatures. This requires a higher level of engineering expertise.

When to Choose Vacuum Brazing

Your choice of a joining process depends entirely on the priorities of your project. Use these guidelines to make an informed decision.

- If your primary focus is mission-critical reliability (Aerospace, Medical): Vacuum brazing is your default choice for creating pure, void-free joints that will not fail under extreme conditions.

- If your primary focus is joining dissimilar or sensitive materials: This process excels where welding fails, allowing you to join metals to ceramics or reactive alloys without compromising their metallurgical properties.

- If your primary focus is efficient production of complex assemblies: Vacuum brazing can be highly cost-effective by combining multiple thermal processes into a single, highly repeatable cycle, eliminating post-processing cleanup.

Ultimately, choosing vacuum brazing is a strategic decision to prioritize the quality and integrity of the final bond above all else.

Summary Table:

| Key Aspect | Vacuum Brazing Advantage |

|---|---|

| Joint Quality | Exceptionally clean, strong, and distortion-free joints |

| Oxidation Prevention | No flux required; eliminates contamination and corrosion |

| Thermal Control | Uniform heating/cooling minimizes stress and distortion |

| Material Versatility | Joins dissimilar materials and sensitive alloys effectively |

| Process Integration | Can combine brazing with heat treatment in a single cycle |

Struggling with unreliable joints or material limitations in your high-performance components? KINTEK's advanced high-temperature furnace solutions, including our specialized Vacuum & Atmosphere Furnaces, are engineered to deliver the precision and purity required for mission-critical vacuum brazing. Leveraging our exceptional R&D and in-house manufacturing, we provide deep customization to precisely meet your unique application requirements, whether for aerospace, medical devices, or complex automotive assemblies. Contact KINTEL today to discuss how our expertise can ensure the integrity of your most demanding projects.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments