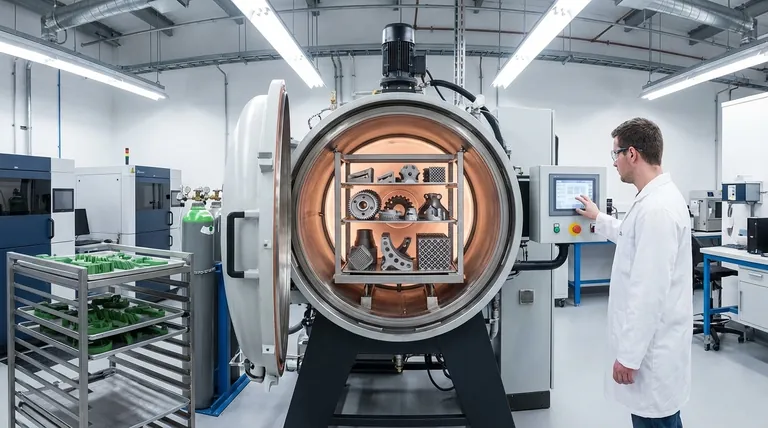

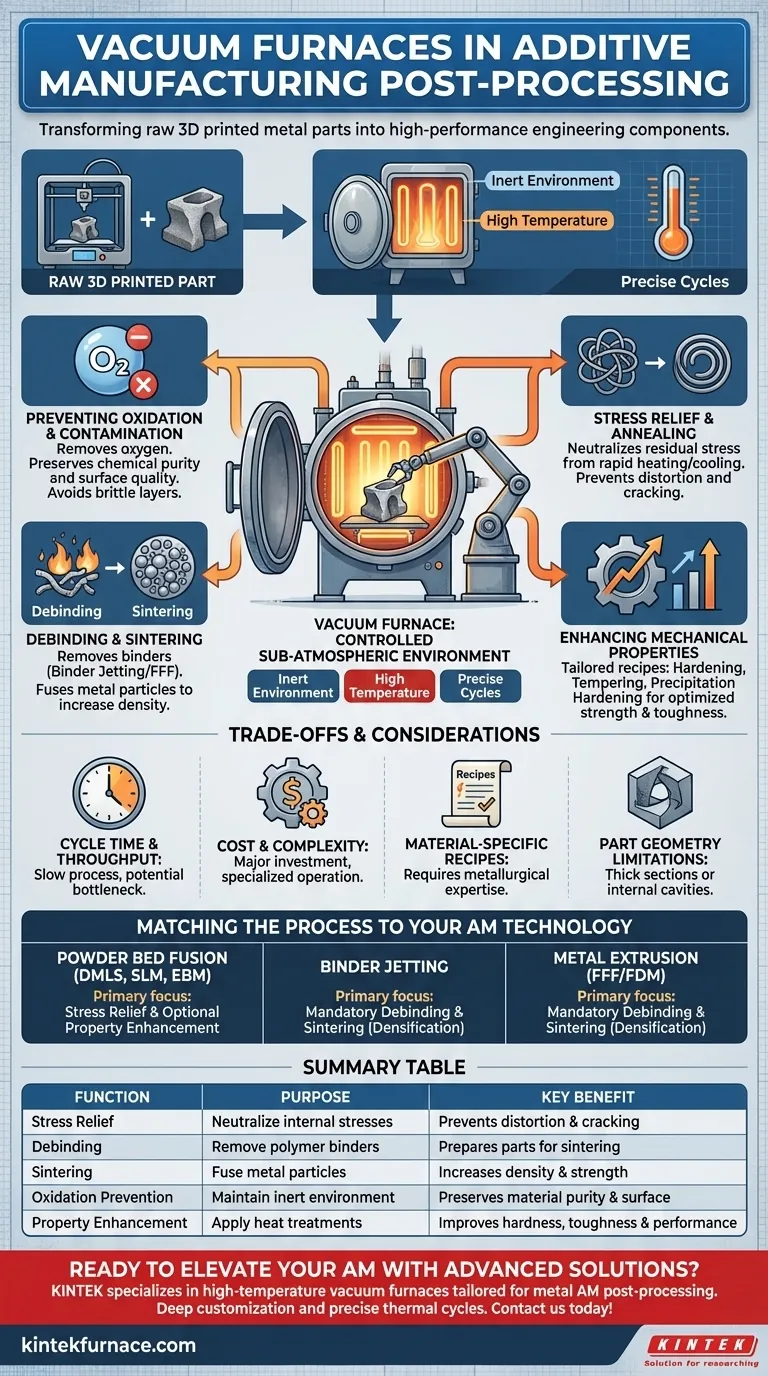

In additive manufacturing, vacuum furnaces are essential post-processing tools used to transform 3D printed metal parts from a raw state into finished, high-performance components. They accomplish this through controlled thermal cycles in a sub-atmospheric environment for processes like stress relief, debinding, and sintering, which are critical for enhancing a part's final density, mechanical properties, and structural integrity.

A vacuum furnace provides a pristine, controlled environment that is indispensable for metal AM. It allows for the precise thermal treatments necessary to remove internal stresses, eliminate binding agents, and fuse metal particles, ultimately converting a printed object into a reliable, engineering-grade component.

The Core Functions of Vacuum Furnaces in AM

Additive manufacturing, particularly with metals, creates parts that are not ready for use right off the build plate. A vacuum furnace is where the material's underlying microstructure is refined and perfected.

Preventing Oxidation and Contamination

The primary purpose of the vacuum is to remove atmospheric gases, especially oxygen. At the high temperatures required for heat treatment, reactive metals like titanium, aluminum, and certain steels will rapidly oxidize if oxygen is present.

This oxidation creates a brittle surface layer, compromises the material's integrity, and can prevent proper sintering. A vacuum ensures the part is heated in an inert environment, preserving its chemical purity and surface quality.

Stress Relief and Annealing

Processes like Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) involve extremely rapid heating and cooling cycles. This induces significant residual stress within the part's internal structure.

If left untreated, these stresses can lead to part distortion, cracking, and premature failure in service. A controlled heating and cooling cycle inside a vacuum furnace, known as stress relief or annealing, allows the material's crystal structure to relax, neutralizing these internal forces and ensuring dimensional stability.

Debinding and Sintering

Technologies like Binder Jetting and Metal Fused Filament Fabrication (FFF) produce a "green part"—a composite of metal powder held together by a polymer binder. The furnace performs two critical functions here.

First is debinding, where the part is heated slowly to a moderate temperature. This burns off the polymer binder without disturbing the fragile arrangement of metal particles.

Second is sintering. After debinding, the temperature is raised to just below the metal's melting point. At this temperature, the metal particles fuse together, eliminating the pores between them and densifying the part to its final, solid state.

Enhancing Mechanical Properties

Beyond just fixing issues, a vacuum furnace is used to actively improve material properties through specific heat treatment "recipes."

This can include hardening to increase strength, tempering to improve toughness, or precipitation hardening (aging) to optimize the strength-to-weight ratio in alloys like aluminum or Inconel. This control allows engineers to tailor the final part's performance to the exact demands of the application.

Understanding the Trade-offs and Considerations

While indispensable, integrating vacuum furnaces into a workflow is a significant technical and financial decision. Objectivity requires acknowledging the associated challenges.

Cycle Time and Throughput

Vacuum furnace cycles are not fast. Achieving a deep vacuum, ramping up to temperature, holding (soaking), and then cooling down can take many hours, sometimes even days for complex cycles. This can create a bottleneck in high-volume production environments.

Cost and Complexity

Vacuum furnaces represent a major capital investment. They are complex systems that require specialized knowledge for operation, programming thermal cycles, and routine maintenance of vacuum pumps, heating elements, and control systems.

Material-Specific Recipes

A vacuum furnace is not a "one-size-fits-all" appliance. Each metal alloy requires a unique, carefully developed thermal profile to achieve the desired outcome. Developing and validating these recipes demands significant metallurgical expertise and experimentation.

Part Geometry Limitations

For processes like binder jetting, extremely thick cross-sections or complex, enclosed internal cavities can pose a challenge. These features can trap binder byproducts during debinding or prevent uniform sintering, leading to defects in the final part.

Matching the Process to Your AM Technology

The specific use of a vacuum furnace depends entirely on the additive manufacturing technology you are using.

- If your primary focus is Powder Bed Fusion (DMLS, SLM, EBM): Your main goal is stress relief to ensure dimensional stability and prevent cracking, followed by optional heat treatments to refine the microstructure and enhance mechanical properties.

- If your primary focus is Binder Jetting: Your process is a mandatory two-stage thermal cycle of debinding to remove the polymer binder and sintering to densify the metal powder into a solid part.

- If your primary focus is Metal Extrusion (FFF/FDM): Your workflow is functionally identical to binder jetting, requiring both debinding and sintering to transform the filament-based green part into a dense metal component.

Mastering thermal post-processing is how you unlock the true engineering potential of your 3D printed metal parts.

Summary Table:

| Function | Purpose | Key Benefit |

|---|---|---|

| Stress Relief | Neutralize internal stresses | Prevents distortion and cracking |

| Debinding | Remove polymer binders | Prepares parts for sintering |

| Sintering | Fuse metal particles | Increases density and strength |

| Oxidation Prevention | Maintain inert environment | Preserves material purity and surface quality |

| Property Enhancement | Apply heat treatments | Improves hardness, toughness, and performance |

Ready to elevate your additive manufacturing with advanced vacuum furnace solutions? KINTEK specializes in high-temperature furnaces, including Vacuum & Atmosphere Furnaces, tailored for metal AM post-processing. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring precise thermal cycles for stress relief, debinding, and sintering. Contact us today to discuss how we can help you achieve reliable, engineering-grade components! Get in touch now

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion