At its core, the role of a vacuum furnace in medical device manufacturing is to perform high-temperature heat treatment in a controlled environment devoid of atmospheric gases. This prevents oxidation and contamination, ensuring that components like implants and surgical instruments meet the absolute highest standards for purity, strength, and patient safety.

The crucial insight is that for medical devices, the "vacuum" is more important than the "furnace." While heat shapes the material, the vacuum protects it, guaranteeing a level of cleanliness and structural integrity that is impossible to achieve in a standard atmospheric furnace.

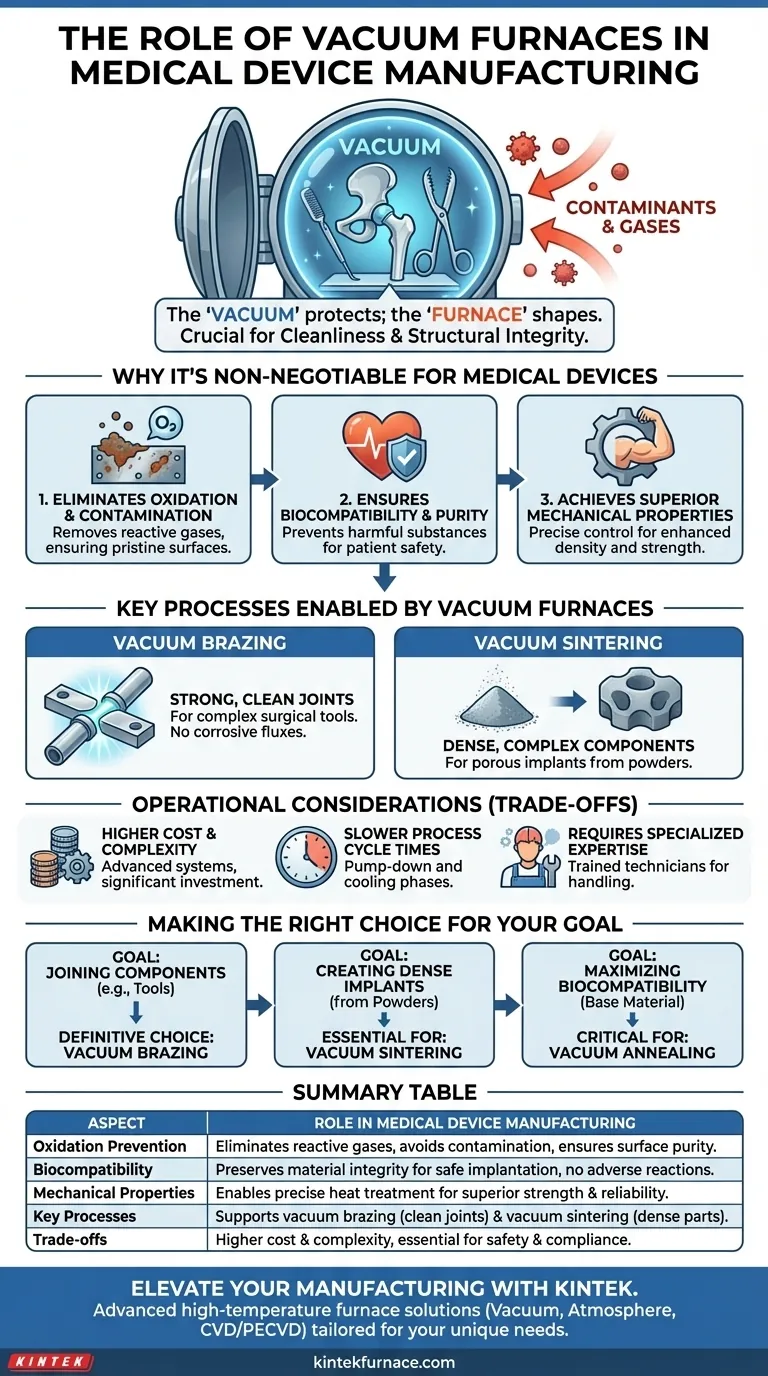

Why a Vacuum is Non-Negotiable for Medical Devices

The decision to use a vacuum furnace is driven by the stringent, non-negotiable requirements of the medical field. The environment in which a material is processed directly impacts its final performance and safety.

Eliminating Oxidation and Contamination

At high temperatures, reactive gases in the air—primarily oxygen—will react with the surface of most metals. This creates a brittle, discolored oxide layer that compromises the material's integrity.

A vacuum furnace removes these reactive gases before heating begins. This ensures the part's surface remains pristine, shiny, and free from any contaminants that could cause adverse reactions in a patient.

Ensuring Biocompatibility and Purity

For any device intended for implantation, biocompatibility is the primary concern. The material must not leach harmful substances or trigger an immune response.

By preventing the formation of oxides and other surface compounds, vacuum processing is a critical step in preserving the inherent purity and biocompatibility of materials like titanium and stainless steel.

Achieving Superior Mechanical Properties

Vacuum furnaces allow for extremely precise control over heating and cooling cycles. This controlled environment enables processes like annealing and sintering to produce parts with enhanced density, strength, and reliability.

The absence of atmospheric interference ensures that the material's final properties are consistent and meet exact engineering specifications, which is vital for high-stress applications like orthopedic implants.

Key Processes Enabled by Vacuum Furnaces

Vacuum furnaces are not used for just one task; they are versatile platforms for several critical manufacturing processes that are foundational to modern medical technology.

Vacuum Brazing for Strong, Clean Joints

Vacuum brazing is a process used to join multiple components into a single assembly using a filler metal. It is essential for creating complex surgical instruments and diagnostic equipment.

The process occurs in a vacuum, resulting in exceptionally strong, clean, and leak-proof joints without the use of corrosive fluxes. This cleanliness is vital for instruments that must be repeatedly sterilized.

Vacuum Sintering for Complex, Dense Components

Vacuum sintering is used to fuse powdered materials (metals or ceramics) into a solid, high-density part. This is a key technology for producing intricately shaped components that are difficult to machine.

This process is critical for manufacturing certain types of porous implants that encourage bone growth, as well as for creating highly durable ceramic components with superior mechanical strength.

Understanding the Trade-offs

While indispensable for high-quality outcomes, vacuum furnace technology is a strategic choice with specific operational considerations.

Higher Initial Cost and Complexity

Vacuum furnaces are sophisticated systems that represent a significant capital investment compared to traditional atmospheric furnaces. They incorporate complex vacuum pumps, seals, and control systems.

Slower Process Cycle Times

Achieving a high vacuum is not instantaneous. The time required to pump down the chamber before heating and to cool the parts under vacuum can result in longer overall cycle times.

Requirement for Specialized Expertise

Operating and maintaining a vacuum furnace requires highly trained technicians. Proper handling is crucial to prevent leaks, manage material outgassing, and ensure consistent, repeatable results.

Making the Right Choice for Your Goal

The application of vacuum furnace technology is directly tied to the specific requirements of the medical component being manufactured.

- If your primary focus is joining components for surgical tools or diagnostic equipment: Vacuum brazing is the definitive choice for creating clean, high-strength, and hermetically sealed joints.

- If your primary focus is creating dense, complex-shaped implants from powders: Vacuum sintering is essential for achieving the required mechanical properties and microstructural purity.

- If your primary focus is maximizing the biocompatibility of a base material: Vacuum heat treatments like annealing are critical for purifying the material and ensuring its surface integrity.

Ultimately, investing in vacuum furnace technology is a direct investment in product reliability and, most importantly, in patient safety.

Summary Table:

| Aspect | Role in Medical Device Manufacturing |

|---|---|

| Oxidation Prevention | Eliminates reactive gases to avoid contamination and ensure surface purity. |

| Biocompatibility | Preserves material integrity for safe implantation without adverse reactions. |

| Mechanical Properties | Enables precise heat treatment for superior strength and reliability in components. |

| Key Processes | Supports vacuum brazing for clean joints and vacuum sintering for dense parts. |

| Trade-offs | Higher cost and complexity, but essential for patient safety and regulatory compliance. |

Ready to elevate your medical device manufacturing with reliable, high-purity heat treatment solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories and medical device producers. Our product line, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Ensure your devices meet the highest standards of purity and safety—contact us today to discuss how our expertise can benefit your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics