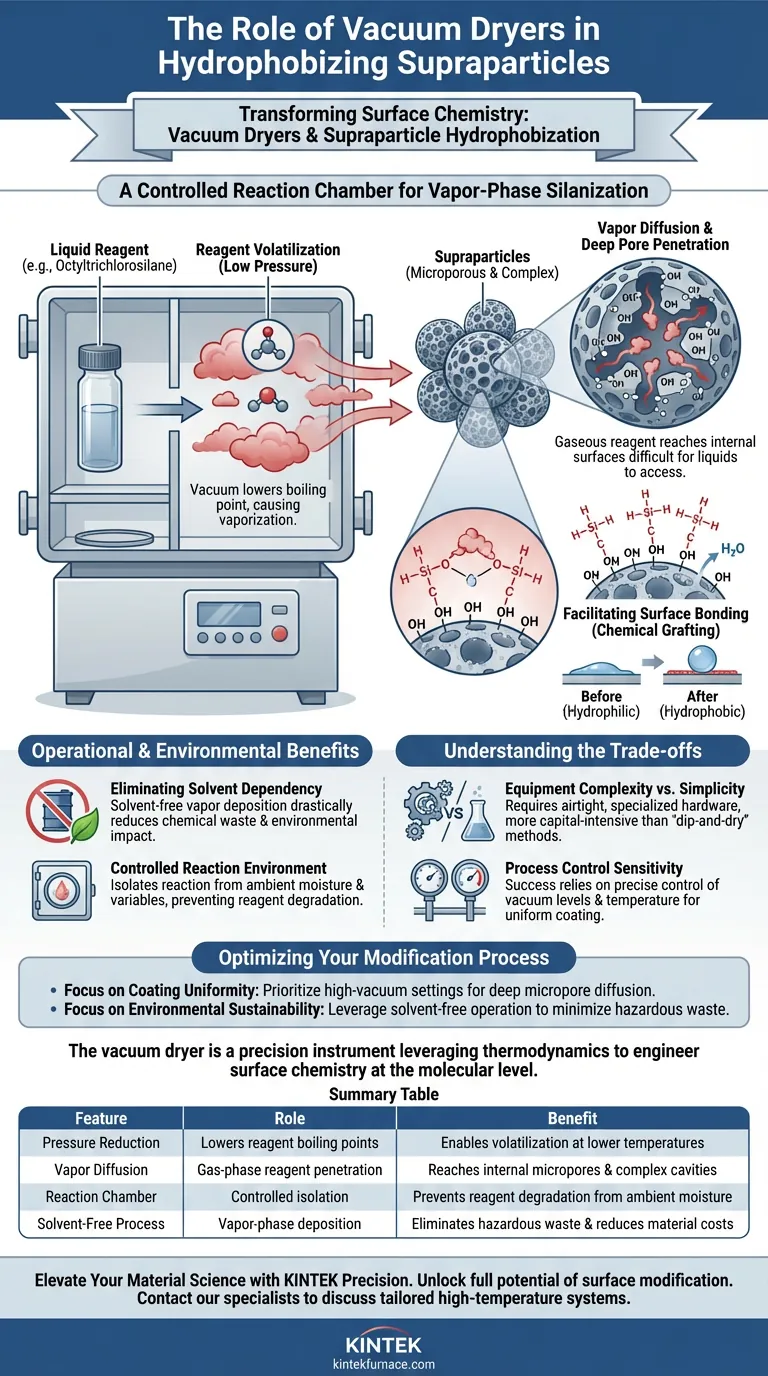

A vacuum dryer functions as a controlled reaction chamber that facilitates vapor-phase silanization, a process essential for rendering supraparticles hydrophobic. Instead of merely drying materials, the device creates a low-pressure environment that allows liquid hydrophobic reagents to turn into vapor and coat complex particle surfaces.

By lowering the atmospheric pressure, the vacuum dryer enables silanization agents to volatilize and diffuse deeply into micropores that liquid solvents often cannot reach. This promotes a uniform chemical reaction with surface silanol groups, achieving high-quality hydrophobicity without the environmental impact of organic solvents.

The Mechanism of Vapor-Phase Modification

Enabling Reagent Volatilization

The primary role of the vacuum dryer in this context is to manipulate phase changes.

Under standard atmospheric pressure, reagents like octyltrichlorosilane remain in liquid form.

By significantly reducing the pressure, the vacuum dryer lowers the boiling point of these reagents, causing them to vaporize (sublimate) at manageable temperatures.

Achieving Deep Pore Penetration

Supraparticles often possess complex, porous structures that are difficult to coat uniformly.

Liquid coating methods can lead to pore blockage or surface tension issues that prevent the reagent from reaching internal surfaces.

In a vacuum environment, the gaseous reagent diffuses freely, penetrating the micropores and internal cavities of the supraparticles to ensure complete coverage.

Facilitating Surface Bonding

Once the reagent vapor reaches the particle surface, a chemical reaction occurs.

The hydrophobic molecules react efficiently with silanol groups present on the silica surface of the supraparticles.

This chemical grafting permanently alters the surface properties, transitioning the material from hydrophilic (water-attracting) to hydrophobic (water-repelling).

Operational and Environmental Benefits

Eliminating Solvent Dependency

Traditional hydrophobization often requires submerging particles in large volumes of organic solvents.

The vacuum dryer approach uses a solvent-free vapor deposition method.

This drastically reduces chemical waste, lowers material costs, and minimizes the environmental footprint of the manufacturing process.

Creating a Controlled Reaction Environment

Vacuum dryers are designed to isolate the reaction from external variables.

As noted in broader applications, these devices efficiently remove residual air and moisture from the chamber.

For silanization specifically, this isolation ensures that the reagent reacts with the particle surface rather than with atmospheric moisture, which could degrade the reagent before it bonds.

Understanding the Trade-offs

Equipment Complexity vs. Simplicity

While effective, vacuum drying requires specialized, airtight hardware capable of sustaining low pressures.

This is inherently more complex and capital-intensive than simple "dip-and-dry" liquid coating methods.

Process Control Sensitivity

The success of vapor-phase silanization relies on precise control of vacuum levels and temperature.

If the pressure is not sufficiently low, the reagent may not volatilize effectively, leading to uneven coating.

Conversely, aggressive vacuum settings without proper thermal regulation could remove the reagent from the chamber before it has time to react with the particles.

Optimizing Your Modification Process

To maximize the effectiveness of a vacuum dryer for hydrophobicity, consider your specific project constraints:

- If your primary focus is coating uniformity: Prioritize high-vacuum settings to ensure the reagent vapor can diffuse into the deepest micropores of the supraparticle.

- If your primary focus is environmental sustainability: Leverage the vacuum's ability to operate solvent-free, minimizing the use of hazardous organic carriers.

The vacuum dryer is not just a drying tool; it is a precision instrument that leverages thermodynamics to engineer surface chemistry at the molecular level.

Summary Table:

| Feature | Role in Hydrophobization | Benefit for Supraparticles |

|---|---|---|

| Pressure Reduction | Lowers reagent boiling points | Enables volatilization at lower temperatures |

| Vapor Diffusion | Gas-phase reagent penetration | Reaches internal micropores & complex cavities |

| Reaction Chamber | Controlled isolation | Prevents reagent degradation from ambient moisture |

| Solvent-Free Process | Vapor-phase deposition | Eliminates hazardous waste & reduces material costs |

Elevate Your Material Science with KINTEK Precision

Unlock the full potential of your surface modification processes with KINTEK’s high-performance laboratory equipment. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Vacuum, Muffle, Tube, Rotary, and CVD systems designed to meet the rigorous demands of advanced chemical modification.

Whether you are performing complex vapor-phase silanization or standard material drying, our customizable solutions ensure uniform coating, precise thermal regulation, and unmatched reliability.

Ready to optimize your lab's performance? Contact our specialists today to discuss how our tailored high-temperature systems can solve your unique research challenges.

Visual Guide

References

- A Supraparticle‐Based Approach to Robust Biomimetic Superhydrophobic Coatings. DOI: 10.1002/smll.202505850

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- How do vacuum furnaces improve efficiency for processes requiring carburizing? Boost Quality and Cut Costs

- How does a high-temperature vacuum furnace facilitate the transparency of magnesium aluminum spinel ceramics?

- How do the operation and maintenance features of vacuum sintering furnaces enhance efficiency? Boost Productivity and Cut Costs

- Why is degassing using a vacuum system and Schlenk line critical in the preparation of black indium oxide? Ensure Purity.

- What is the temperature of a vacuum furnace? Achieve High-Purity Thermal Processing

- What critical process environments does a high-vacuum furnace provide for boron carbide? Achieve Superior Densification

- What technical requirements must a furnace meet for Inconel 718 hardening? Master Precision Aging & Cooling

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing