To successfully precipitation harden Inconel 718, a laboratory box or atmosphere furnace requires rigorous thermal precision and specialized cooling capabilities. Specifically, the equipment must be programmable to execute complex two-stage aging cycles and provide the mechanism for rapid air cooling or water quenching immediately following solution treatment.

Core Takeaway The effectiveness of Inconel 718 hardening relies entirely on the furnace's ability to drive specific microstructural changes. You need equipment that guarantees tight temperature control to precipitate strengthening phases (Gamma Double Prime and Gamma Prime) and facilitates rapid cooling to regulate the Delta phase.

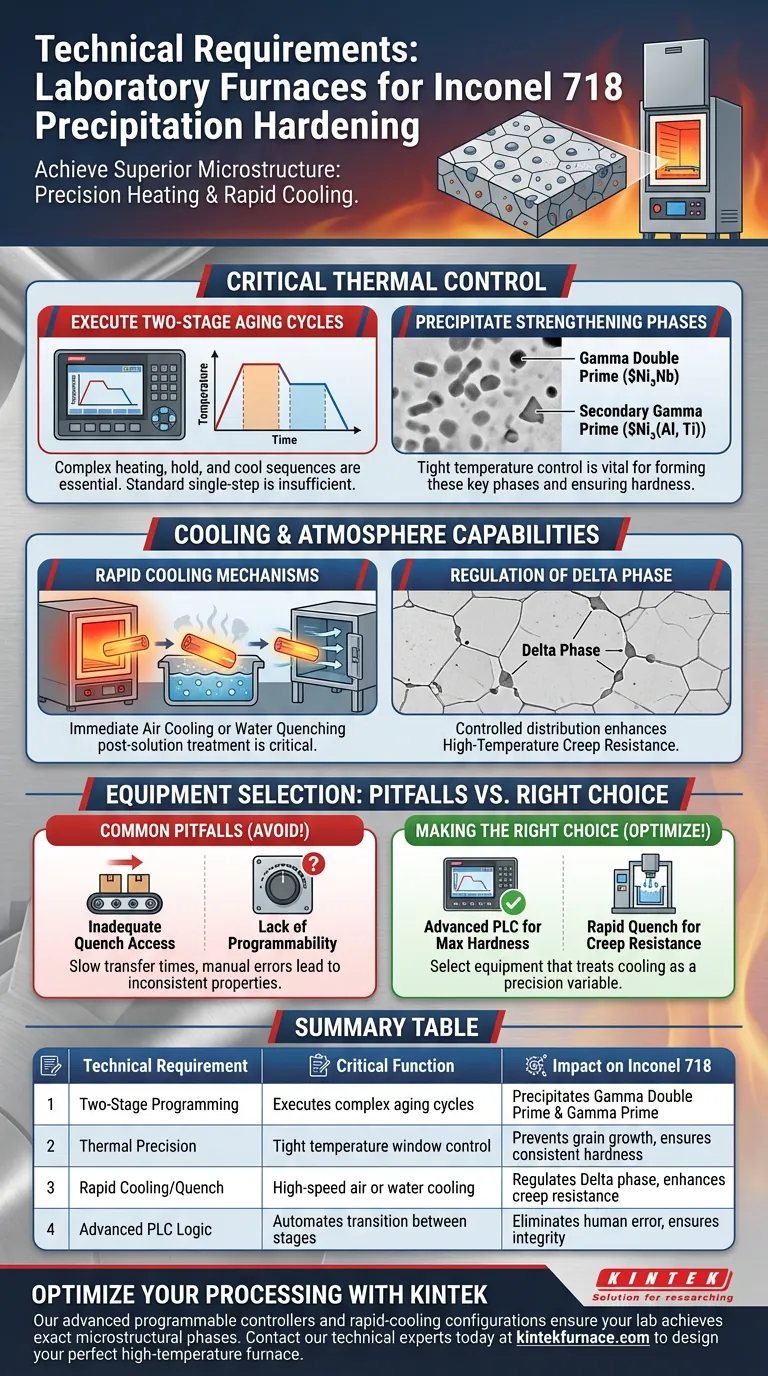

Critical Thermal Control Requirements

To achieve the desired mechanical properties in Inconel 718, the furnace must offer more than simple heating; it requires dynamic control logic.

Executing Two-Stage Aging Cycles

Standard single-step heating is insufficient for this superalloy. The furnace controller must be capable of programming and executing a distinct two-stage aging cycle.

This process involves holding the material at a specific temperature, altering the temperature for a second dwell time, and then cooling at a controlled rate.

Precipitating Strengthening Phases

The primary goal of this thermal precision is the formation of specific precipitates. The furnace environment must facilitate the nucleation of Gamma Double Prime ($Ni_3Nb$).

Simultaneously, the cycle must encourage the formation of secondary Gamma Prime ($Ni_3(Al, Ti)$). If the furnace temperature fluctuates outside the specific processing window, these strengthening phases will not form correctly, compromising the alloy's hardness.

Cooling and Atmosphere Capabilities

Heating is only half of the precipitation hardening equation; the method of cooling is equally critical for microstructural integrity.

Rapid Cooling Mechanisms

The furnace setup must accommodate rapid air cooling or water quenching. This is particularly vital following the solution treatment phase, often performed prior to the aging steps.

Slow or uncontrolled cooling can lead to undesirable grain growth or the formation of brittle phases that reduce the material's fatigue life.

Regulation of the Delta Phase

Proper cooling and temperature maintenance are required to control the distribution of the Delta phase.

While an excess of Delta phase can be detrimental, a regulated distribution is necessary to enhance the material's high-temperature creep resistance. The furnace's ability to transition quickly between heating and cooling states directly impacts this distribution.

Common Pitfalls in Equipment Selection

When selecting a furnace for Inconel 718, failing to account for thermal responsiveness is a frequent error.

Inadequate Quench Access

A standard box furnace often lacks the accessibility required for immediate quenching. If the transfer time from the hot zone to the quench media (water or air blast) is too long, the material temperature drops uncontrolled, leading to inconsistent properties.

Lack of Programmability

Manual set-point controllers are ill-suited for Inconel 718. Relying on an operator to manually adjust temperatures for the two-stage aging cycle introduces human error and timing inconsistencies that ruin the microstructure.

Making the Right Choice for Your Project

The specific configuration of your furnace should be dictated by your end-goal for the material's performance.

- If your primary focus is maximum hardness and strength: Prioritize a furnace with advanced programmable logic controllers (PLCs) to ensure the two-stage aging cycle creates optimal Gamma Double Prime density.

- If your primary focus is high-temperature creep resistance: Ensure the equipment allows for rapid, repeatable quenching to strictly regulate the Delta phase distribution.

Select equipment that treats cooling as a precision variable, not just an afterthought.

Summary Table:

| Technical Requirement | Critical Function | Impact on Inconel 718 |

|---|---|---|

| Two-Stage Programming | Executes complex aging cycles | Precipitates Gamma Double Prime ($Ni_3Nb$) and Gamma Prime |

| Thermal Precision | Tight temperature window control | Prevents grain growth and ensures consistent hardness |

| Rapid Cooling/Quench | High-speed air or water cooling | Regulates Delta phase and enhances creep resistance |

| Advanced PLC Logic | Automates transition between stages | Eliminates human error and ensures microstructural integrity |

Optimize Your Superalloy Processing with KINTEK

Precision is non-negotiable when hardening Inconel 718. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique metallurgical needs. Our advanced programmable controllers and rapid-cooling configurations ensure your lab achieves the exact microstructural phases required for superior hardness and creep resistance.

Ready to elevate your material science? Contact our technical experts today to design the perfect high-temperature furnace for your application.

Visual Guide

References

- Sheida Sarafan, Prakash Patnaik. Elevated-Temperature Tensile Behavior and Properties of Inconel 718 Fabricated by In-Envelope Additive–Subtractive Hybrid Manufacturing and Post-Process Precipitation Hardening. DOI: 10.3390/jmmp8060297

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does microwave sintering equipment achieve efficient heating? Unlock Rapid BCZY Electrolyte Thin Film Densification

- What are the advantages of using a constant temperature vacuum drying oven for iron phosphate? Ensure Battery Purity

- Why is a laboratory high-temperature melting furnace critical for glass-based immobilization? Master Matrix Preparation

- What role does a reduction furnace play in the activation of CuO-Fe3O4 catalysts? Master Catalyst Engineering

- How do chillers improve product quality in heat treatment? Achieve Precise, Repeatable Cooling for Superior Results

- How do customized vacuum furnaces meet specific process requirements? Tailor Your Heat Treatment for Maximum Efficiency

- What are the specifications for resistance heating in vacuum graphitizing furnaces? Achieve Superior Graphitization for Large-Scale Production

- How can the cooling rate of vacuum sintering be increased? Boost Efficiency with Gas-Assisted Cooling