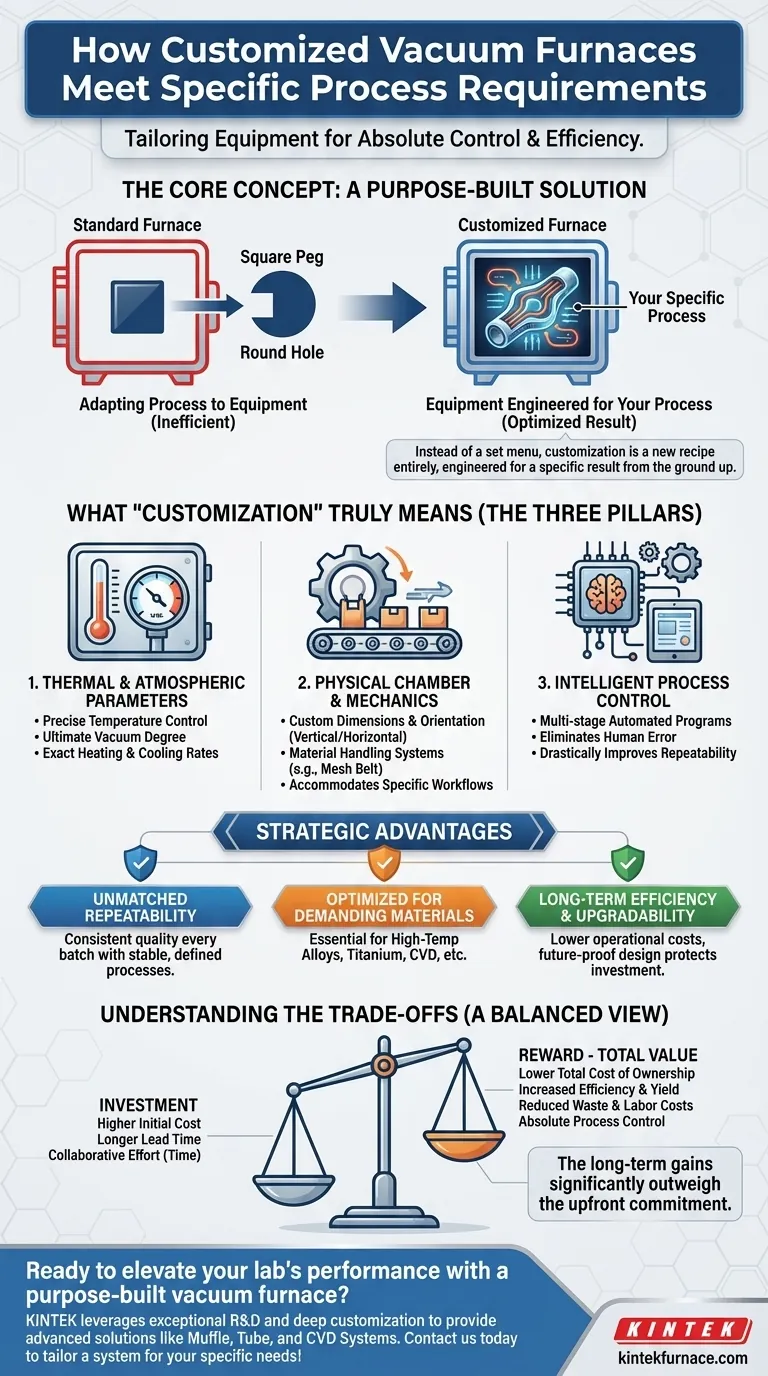

At its core, a customized vacuum furnace meets specific process requirements by tailoring its fundamental operational parameters and physical design to your exact application. Instead of adapting your process to a standard piece of equipment, the equipment is engineered from the ground up to optimize your specific material, part geometry, and desired outcome.

The true value of a custom vacuum furnace is not merely achieving unique specifications. It is about creating a purpose-built system that integrates perfectly with your production goals, ensuring maximum efficiency, repeatability, and final product quality.

Beyond the Spec Sheet: What "Customization" Truly Means

Standard furnaces offer a set menu of options. Customization is about creating a new recipe entirely, engineered for a specific result. This involves re-evaluating the furnace from its foundational components upward.

Tailoring Core Thermal and Atmospheric Parameters

The most critical customization involves the process environment itself. This includes defining the heating temperature, the ultimate vacuum degree, and the precise heating and cooling rates.

Controlling these variables with high precision is essential for achieving desired material properties, whether you are brazing, sintering, or performing another form of heat treatment.

Adapting the Physical Chamber and Mechanics

A furnace must physically accommodate your parts and workflow. Customization here can involve the furnace's internal dimensions, the orientation (vertical or horizontal), and the material handling systems.

For example, a system can be designed with a stainless steel mesh belt transmission and variable frequency speed regulation to ensure smooth, continuous processing of many small parts.

Integrating Intelligent Process Control

Modern custom furnaces rely on sophisticated automation. A system can be built with a multi-stage intelligent program-controlled temperature control system to manage heating, soaking, and cooling cycles automatically.

This removes the potential for human error, drastically improves process repeatability, and reduces the need for constant operator oversight, directly lowering operational costs.

The Strategic Advantage of a Purpose-Built System

Opting for a custom solution is an investment in process control. The benefits extend far beyond simply meeting a unique temperature or vacuum requirement.

Achieving Unmatched Process Repeatability

By designing the controls, heating elements, and vacuum system around a single, well-defined process, you achieve unparalleled stability and repeatability. This ensures every batch meets the exact same quality standard.

Optimizing for Demanding Materials and Applications

Customization is often essential for advanced materials like high-temperature alloys, stainless steel, and titanium alloys. It is also critical for specialized processes like Chemical Vapor Deposition (CVD), where a standard system may not suffice.

Expert engineers collaborate with you to ensure the final design meets the unique challenges posed by your specific application.

Designing for Long-Term Efficiency and Upgradability

A well-designed custom furnace is built with the entire lifecycle in mind. They are engineered for ease of maintenance and can be designed with future upgrades in mind.

This forward-thinking approach ensures the equipment can evolve with your production demands, protecting your initial investment.

Understanding the Trade-offs

A custom furnace is a powerful solution, but it requires a clear understanding of the associated commitments. It is not an off-the-shelf purchase but a collaborative engineering project.

The Importance of a Collaborative Partnership

Success hinges on close collaboration with the furnace manufacturer. You provide the process expertise; they provide the equipment engineering expertise. This partnership requires a significant investment of time for consultation and specification.

The manufacturer typically provides comprehensive support, including installation, commissioning, and operator training to ensure the system is utilized efficiently.

Initial Investment vs. Total Cost of Ownership

The upfront capital cost of a custom furnace will be higher than a standard model. However, this cost must be weighed against the long-term gains from increased efficiency, reduced waste, lower labor costs, and higher product yield.

Lead Time and Specification Lock-in

A custom-engineered system naturally has a longer lead time than a standard product. Furthermore, once the core design parameters are finalized and manufacturing begins, major changes become difficult and costly.

Making the Right Choice for Your Goal

The decision to choose a standard or custom furnace should be driven by your primary objective.

- If your primary focus is experimental R&D: A custom furnace can be built to accommodate the atypical specifications and extreme parameters needed for exploring new processes.

- If your primary focus is high-volume, high-yield production: A custom, automated system designed for your specific part and process will deliver the best long-term efficiency and repeatability.

- If your primary focus is processing challenging or advanced materials: Customizing the thermal and atmospheric controls is often the only way to reliably achieve the required material properties.

Ultimately, choosing a custom vacuum furnace is an investment in absolute control over your most critical manufacturing processes.

Summary Table:

| Customization Aspect | Key Features | Benefits |

|---|---|---|

| Thermal & Atmospheric Parameters | Precise temperature control, ultimate vacuum degree, heating/cooling rates | Achieves desired material properties, enhances process control |

| Physical Chamber & Mechanics | Custom dimensions, orientation (vertical/horizontal), material handling systems | Accommodates specific parts and workflows, improves throughput |

| Intelligent Process Control | Multi-stage program-controlled automation, error reduction | Increases repeatability, lowers operational costs, reduces human error |

| Strategic Advantages | Unmatched repeatability, optimization for advanced materials, long-term efficiency | Ensures high product quality, supports demanding applications, protects investment |

Ready to elevate your lab's performance with a purpose-built vacuum furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met precisely, delivering maximum efficiency, repeatability, and quality. Contact us today to discuss how we can tailor a system for your specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures