Microwave sintering equipment achieves efficient heating by directly coupling a microwave electromagnetic field with the dielectric loss characteristics of the BCZY ceramic material. Instead of applying heat externally, this interaction causes the entire volume of the material to generate its own heat internally, resulting in a rapid and uniform temperature rise.

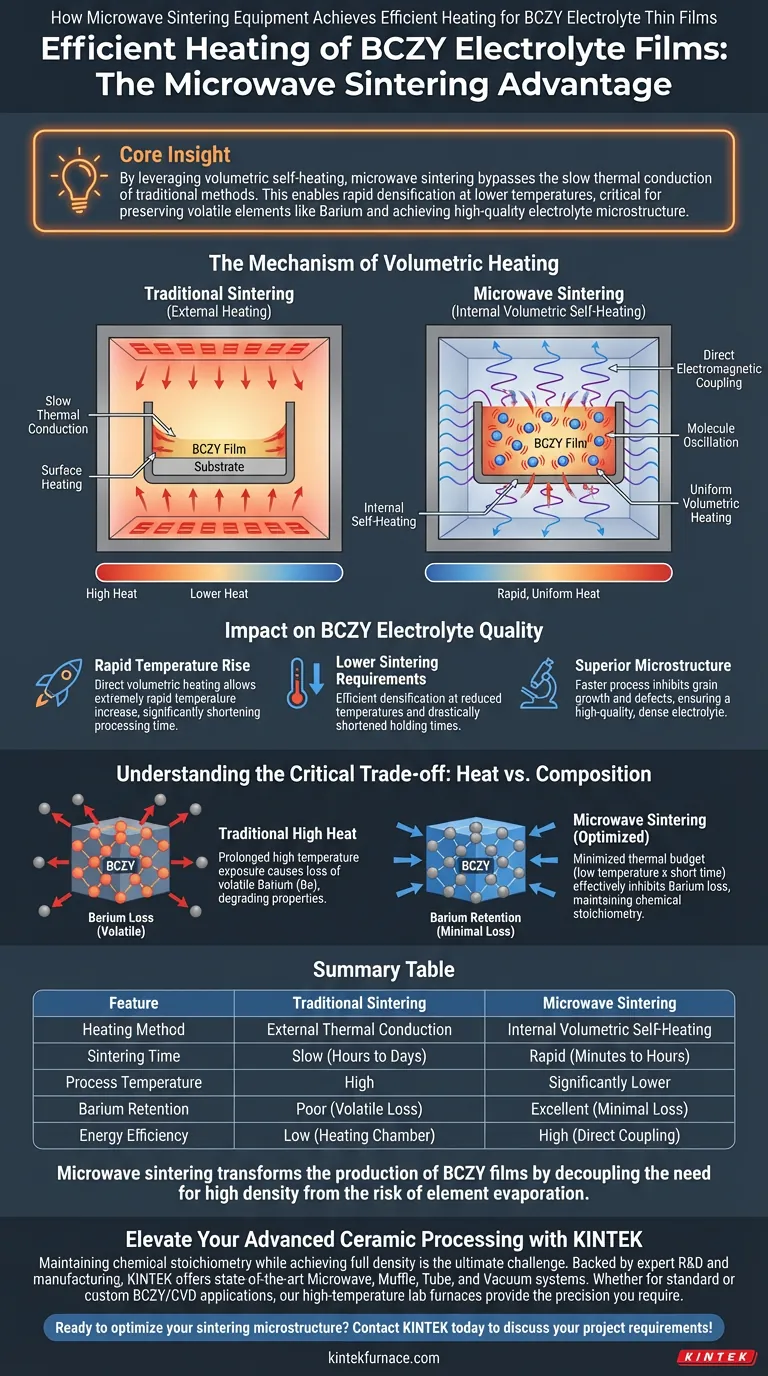

Core Insight: By leveraging volumetric self-heating, microwave sintering bypasses the slow thermal conduction of traditional methods. This enables rapid densification at lower temperatures, which is critical for preserving volatile elements like Barium and achieving a high-quality electrolyte microstructure.

The Mechanism of Volumetric Heating

Direct Electromagnetic Coupling

Traditional ovens rely on heating elements to warm the air, which then warms the surface of the material. Microwave sintering operates differently by generating an electromagnetic field.

This field interacts directly with the dielectric loss mechanism within the ceramic material. The energy is transferred straight to the molecules, forcing them to align and oscillate, which generates thermal energy.

Internal Self-Heating

This process creates a self-heating mode where the material acts as the heat source.

Because the heat is generated internally rather than applied externally, the outcome is volumetric heating. The entire material warms up simultaneously, ensuring high energy efficiency and eliminating the lag time associated with thermal conduction.

Impact on BCZY Electrolyte Quality

Rapid Temperature Rise

The direct nature of volumetric heating allows for an extremely rapid temperature rise.

The equipment can bring the BCZY thin films to the necessary sintering state much faster than conventional furnaces. This significantly shortens the overall processing time.

Lower Sintering Requirements

Microwave sintering is highly efficient, allowing the material to densify at reduced sintering temperatures.

Additionally, the holding times—the duration the material must stay at peak heat—are drastically shortened. This combination of speed and lower heat input is a distinct advantage over resistive heating methods.

Understanding the Critical Trade-off: Heat vs. Composition

The Challenge of Volatility

In ceramic processing, there is often a trade-off between achieving high density (which requires heat) and maintaining chemical composition.

For BCZY electrolytes, prolonged exposure to high temperatures typically causes the loss of volatile elements, specifically Barium (Ba). Loss of Barium degrades the material's properties.

How Microwave Sintering Resolves This

Microwave equipment resolves this trade-off by minimizing the thermal "budget" (temperature x time).

Because the process requires lower temperatures and shorter holding times, it effectively inhibits the loss of Barium. This results in a superior microstructure and density without compromising the chemical stoichiometry of the membrane.

Making the Right Choice for Your Project

Microwave sintering is not just about speed; it is a quality control tool for volatile ceramics.

- If your primary focus is Compositional Integrity: Choose microwave sintering to minimize the evaporation of volatile elements like Barium, ensuring the electrolyte retains its intended chemical structure.

- If your primary focus is Microstructural Density: Utilize the volumetric heating capability to achieve a denser, more uniform membrane than is typically possible with surface-heating methods.

Microwave sintering transforms the production of BCZY films by decoupling the need for high density from the risk of element evaporation.

Summary Table:

| Feature | Traditional Sintering | Microwave Sintering |

|---|---|---|

| Heating Method | External Thermal Conduction | Internal Volumetric Self-Heating |

| Sintering Time | Slow (Hours to Days) | Rapid (Minutes to Hours) |

| Process Temperature | High | Significantly Lower |

| Barium Retention | Poor (Volatile Loss) | Excellent (Minimal Loss) |

| Energy Efficiency | Low (Heating Chamber) | High (Direct Coupling) |

Elevate Your Advanced Ceramic Processing with KINTEK

Maintaining chemical stoichiometry while achieving full density is the ultimate challenge in electrolyte fabrication. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Microwave, Muffle, Tube, and Vacuum systems designed to solve your most complex thermal challenges. Whether you need a standard solution or a system fully customizable for unique BCZY or CVD applications, our high-temperature lab furnaces provide the precision you require.

Ready to optimize your sintering microstructure? Contact KINTEK today to discuss your project requirements!

Visual Guide

References

- Mengyang Yu, Shenglong Mu. Recent Novel Fabrication Techniques for Proton-Conducting Solid Oxide Fuel Cells. DOI: 10.3390/cryst14030225

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Spark Plasma Sintering SPS Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is a hot wall vacuum furnace design? Discover Its Key Benefits and Applications

- How do the cooling properties of argon and nitrogen differ in vacuum furnaces? Compare Speed, Safety, and Material Suitability

- What are the main components of a vacuum brazing oven? Discover the Key Parts for Superior Brazing

- What are the technical advantages of using an Aerodynamic Levitation Furnace? Achieve Ultra-Pure Silicate Melt Research

- What operational advantages do vacuum furnaces provide? Achieve Superior Material Quality and Process Control

- What are the process advantages of RTT vs. vacuum annealing for nickel-silicon? Achieve precise sub-micron control

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What are the advantages of hot wall vacuum furnaces? Lower Costs, Faster Pump-Down for Your Lab