When choosing a vacuum furnace, the design of the heating chamber is a critical decision point. A hot wall vacuum furnace offers distinct advantages, primarily centered on lower manufacturing costs and greater efficiency in achieving a vacuum. Because the heated area is a smaller, self-contained retort, it can be pumped down more rapidly with smaller pumps compared to its cold wall counterpart.

The core decision between a hot wall and cold wall furnace is not about which is universally superior, but which is the correct tool for the job. Hot wall designs provide a cost-effective and efficient solution for lower-temperature processes, while cold wall furnaces are built for high-performance, high-temperature applications.

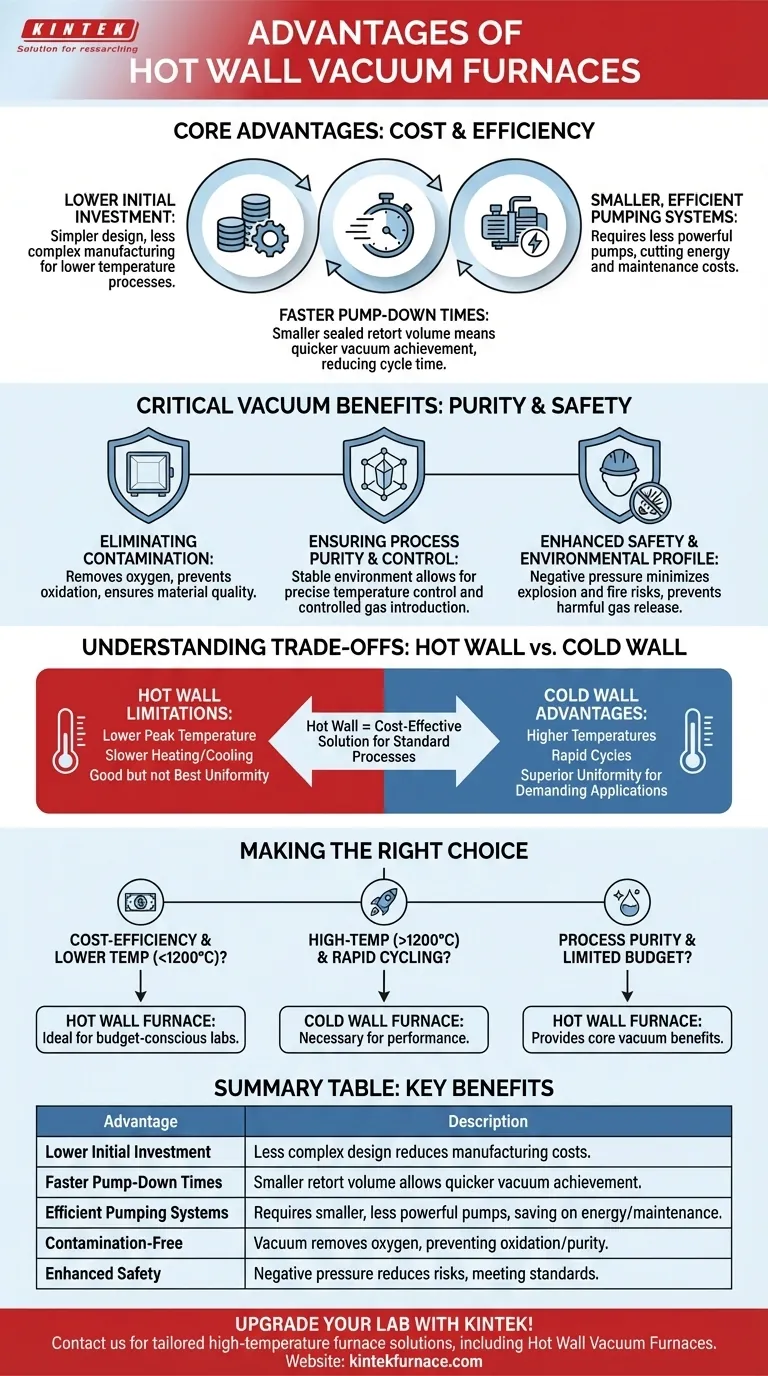

The Core Advantages of Hot Wall Design

The primary benefits of a hot wall furnace stem directly from its construction, where the vacuum chamber (the retort) is located inside the heating elements.

Lower Initial Investment

Hot wall furnaces are generally less complex and therefore less expensive to manufacture than cold wall designs. This makes them an accessible entry point for processes that do not require extreme temperatures.

Faster Pump-Down Times

The sealed retort contains a much smaller volume of gas than the entire chamber of a cold wall furnace. This smaller volume allows vacuum pumps to reach the required pressure level more quickly, reducing overall cycle time.

Smaller, More Efficient Pumping Systems

A direct consequence of the smaller internal volume is that smaller, less powerful vacuum pumps are needed. This not only contributes to the lower initial cost but can also reduce ongoing energy consumption and maintenance expenses.

Why a Vacuum Environment Is Critical

Beyond the specific design, it's important to remember the fundamental benefits that all vacuum furnaces, including hot wall models, provide for material processing.

Eliminating Contamination

The primary function of the vacuum is to remove oxygen and other reactive gases. This creates a contamination-free environment, preventing oxidation, nitridation, and other unwanted chemical reactions that degrade material quality.

Ensuring Process Purity and Control

Materials treated in a vacuum are more stable and pure. The environment allows for extremely precise temperature control and, if needed, the controlled introduction of specific gases to achieve surface cleaning or modification.

Enhanced Safety and Environmental Profile

Operating at negative pressure eliminates the risk of explosion common to pressurized vessels. The low-oxygen atmosphere also minimizes fire risk. Furthermore, the closed system prevents the release of harmful exhaust gases, helping to meet environmental standards.

Understanding the Trade-offs: Hot Wall vs. Cold Wall

To make an informed decision, you must understand the limitations of the hot wall design, which are defined by what the cold wall design does better.

Temperature Limitations

The most significant trade-off is the maximum operating temperature. In a hot wall furnace, the retort material itself is heated and must withstand the process temperature while under vacuum. This inherently limits the furnace's peak temperature compared to cold wall designs, where the vacuum chamber remains cool.

Slower Heating and Cooling

Because the entire retort must be heated and cooled, hot wall furnaces have greater thermal inertia. This results in slower heating and cooling cycles compared to cold wall furnaces, where only the internal heating elements and workload are brought to temperature.

Temperature Uniformity

While providing good uniformity, hot wall furnaces can be surpassed by specialized cold wall designs. Cold wall furnaces often feature more complex and targeted heating element arrangements, allowing for greater precision and temperature uniformity across a larger workload.

Making the Right Choice for Your Process

The ideal furnace design depends entirely on your operational requirements and budget.

- If your primary focus is cost-efficiency for lower-temperature processes (typically below 1200°C): The hot wall furnace is often the superior choice due to its lower initial investment and simpler operation.

- If your primary focus is high-temperature performance (above 1200°C) and rapid cycling: A cold wall furnace is necessary to achieve the required temperatures, speed, and uniformity for demanding applications.

- If your primary focus is process purity on a limited budget: A hot wall furnace provides the core benefits of a vacuum environment for many standard heat-treating, brazing, and sintering tasks without the expense of a high-performance system.

Ultimately, aligning the furnace's capabilities with your specific material and production goals is the key to a successful investment.

Summary Table:

| Advantage | Description |

|---|---|

| Lower Initial Investment | Less complex design reduces manufacturing costs, ideal for budget-conscious labs. |

| Faster Pump-Down Times | Smaller retort volume allows quicker vacuum achievement, cutting cycle times. |

| Efficient Pumping Systems | Requires smaller, less powerful pumps, saving on energy and maintenance. |

| Contamination-Free Environment | Vacuum removes oxygen, preventing oxidation and ensuring material purity. |

| Enhanced Safety | Negative pressure reduces explosion and fire risks, meeting environmental standards. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer hot wall vacuum furnaces and other products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and cost-effectiveness. Contact us today to discuss how we can support your heat treatment and sintering processes with tailored, high-quality equipment!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion