Vacuum Hot Press Furnace

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Item Number : KT-VTP

Price varies based on specs and customizations

- Working temperature

- ≤1150℃

- Vacuum level

- 10-2 torr (Rotary vane pump), 10-4 torr (Turbo pump station)

- Pressure range

- 0-30Mpa

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Reliable PartnerEasy ordering process, quality products, and dedicated support for your business success.

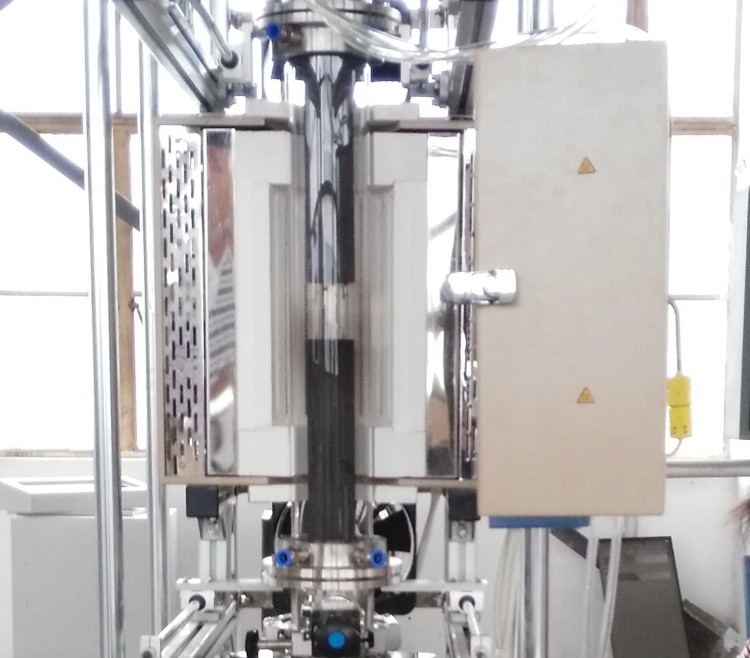

Visual Overview: Vacuum Tube Hot Press Furnace

Advanced Vacuum Tube Hot Press Furnace by KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our extensive product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is a testament to our expertise in thermal processing technology.

A cornerstone of our specialized offerings is the Vacuum Tube Hot Press Furnace. This sophisticated system uniquely combines vacuum/atmosphere control, hot pressing forming, and high-temperature sintering capabilities. It is expertly designed for:

- High-temperature hot forming of new materials such as dry powder metallurgy and functional ceramics.

- Vacuum sintering of alloy materials composed of metals.

- High-temperature sintering of ceramic materials like silicon carbide and silicon nitride.

- Metallurgical bonding of dry powders, even at temperatures below the main component's melting point, to significantly enhance material strength.

Our strong deep customization capability ensures that we can precisely meet your unique experimental requirements. If you have specific needs or require a tailored furnace solution for your research or production, we encourage you to discuss your project with our specialists.

Key Features

The Vacuum Hot Press Furnace is a comprehensive set of equipment designed to heat and pressurize materials under controlled conditions, whether in a vacuum or atmospheric environment. This advanced system is tailored to meet the specific needs of various materials and heating temperatures, offering a range of heating elements such as graphite heaters, molybdenum heaters, and induction heating. The furnace supports both one-way and two-way pressurization through a hydraulic system, ensuring precise control over the pressing process.

Key features of the Vacuum Hot Press Furnace include:

- Versatile Heating Elements: The furnace accommodates different heating elements like graphite and molybdenum heaters, as well as induction heating, allowing for flexibility in processing a wide range of materials at varying temperatures.

- Precise Pressurization Control: With options for one-way or two-way pressurization, the hydraulic system ensures that materials are subjected to the exact pressure required for optimal sintering and compaction.

- Enhanced Material Bonding: Under high temperature and pressure, the furnace facilitates the bonding of raw material particles, promoting grain growth and reducing voids and grain boundaries, which leads to a denser, more compact sintered body.

- Comprehensive System Integration: The furnace is equipped with a robust structure that includes a furnace body, furnace doors, heating and heat preservation systems, temperature measurement systems, vacuum systems, air charging systems, water cooling systems, and a sophisticated control system, all working in harmony to ensure precise and efficient operation.

- Vacuum Environment Optimization: The hot press is designed to operate within a vacuum negative pressure box, which is crucial for preventing oxidation and other adverse reactions during the hot pressing process, thus maintaining the purity and integrity of the materials being processed.

Applications

Vacuum Tube Hot Press Furnaces are widely used in various industries and research fields, offering precise and efficient heating and pressing capabilities. Here are some of their main application areas:

- Sintering of ceramic materials, such as high-performance ceramics, electronic ceramics, and refractory materials

- Hot pressing of metal powders, including hard metals, porous metals, and composite materials

- Heat treatment of materials, such as annealing, hardening, and tempering

- Crystal growth and synthesis of advanced materials

- Production of carbon-carbon composites and other high-temperature composites

- Vacuum brazing and welding

- Research and development of new materials and processes

Core Advantages

- High-temperature accuracy: The advanced touch screen auto temperature controller ensures precise temperature control, providing accurate and reliable results.

- Easy operation: The user-friendly 7-inch touch screen English image interface simplifies operation, making it accessible even for novice users.

- Programmable sintering curves: Up to 15 sintering curves can be preset, allowing for customized heating and cooling profiles to suit specific materials and processes.

- Real-time monitoring: The graphical representation of the sintering curve provides a clear visual overview of temperature changes throughout the process.

- Versatile atmosphere control: The optional gas flowmeter enables atmosphere sintering, allowing for precise control of the gas environment during processing.

- Remote control and data logging: Optional modules can be added to enable remote control and data downloading, facilitating efficient process monitoring and data analysis.

- Wide applications: This Vacuum Tube Furnace finds applications in various fields, including university and research labs, as well as industrial production settings.

- Excellent heat insulation: The furnace's superior heat insulation ensures efficient energy utilization and minimizes heat loss, resulting in cost savings.

- Uniform temperature distribution: The symmetrical heating design ensures uniform temperature distribution within the furnace chamber, promoting consistent and high-quality results.

- Vacuum and inert atmosphere compatibility: The furnace can operate under both vacuum and inert atmosphere conditions, providing flexibility for various processing requirements.

Operating Principle

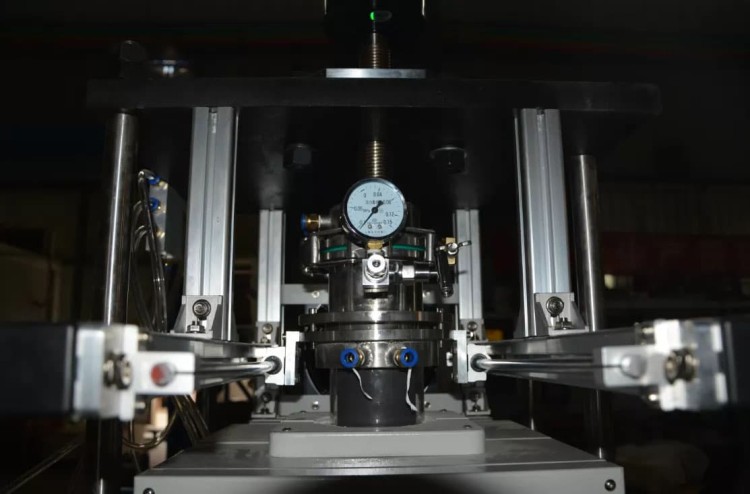

The split vertical heating furnace body is adopted for the vacuum tubular furnace, the vacuum hot pressing chamber is sealed with high temperature furnace tube and stainless steel flange, and the pressure stroke adopts the vacuum corrugated pipe for up and down movement under vacuum state; The electric hydraulic press machine is used for the pressure generating, and the pressure column is made of graphite rod and graphite mold. When powder is heated to the target sintering temperature while pressurized, the target materials can be sintered into dense and uniform products in a short time.

Technical Specifications

| Hydraulic press | Working pressure: 0-30Mpa Travel distance: Pressure stability: ≤1MPa/10min Pressure meter: Digital pressure gauge Drive solution: Electric drive with standby manual drive |

|---|---|

| Vertical split furnace | Working temperature: ≤1150℃ Heating element:Ni-Cr-Al resistance wire with dipped Mo Heating speed: Hot zone length: 300mm Constant temperature zone: 100mm Controller: Touch screen with PID thermal controller Rated power: 2200W |

| Vacuum furnace tube | Tube material: Quartz tube(Optional Alumina/Nickel alloy) Tube diameter: 100mm(Optional 120/160mm) Vacuum sealing: SS flange with silicon O ring Flange cooling method: Inter layer water circulating cooling |

| Graphite pressing die | Die material: High purity graphite (Graphite must work under vacuum to prevent oxidation) Pressure rod diameter: 87mm Sleeve die size: 55mm OD/ 50mm Height Die inserts: OD22.8 x ID20.8 Pushing Rod: 12.7mmOD/40mm Height Other sizes die can be customer made |

| Vacuum pump setup | Rotary vane pump vacuum is up to 10-2 torr Turbo pump station vacuum is up to 10-4 torr |

| Electric power supply | AC110-220V, 50/60HZ |

Explore the possibilities with KINTEK's Vacuum Tube Hot Press Furnace. For detailed specifications, to discuss how this system can be adapted for your specific material processing challenges, or to inquire about our customization options, please contact us today. Our team is ready to assist you in finding the perfect high-temperature solution.

FAQ

What Is A Vacuum Hot Press And How Does It Work?

What Is A Tube Furnace And How Does It Work?

What Are The Main Applications Of A Vacuum Furnace?

What Is The Principle Of A Hot Press Furnace?

What Is A Vacuum Induction Furnace?

What Is An Atmosphere Furnace Used For?

What Are The Common Applications Of A Split Tube Furnace?

What Are The Main Applications Of A Rotary Tube Furnace?

What Are The Main Applications Of Multi-zone Tube Furnaces?

What Are The Main Components Of A Vacuum Hot Press?

What Are The Main Applications Of Tube Furnaces?

What Are The Key Features Of A Vacuum Furnace?

What Are The Applications Of A Hot Press Furnace?

What Are The Main Applications Of Vacuum Induction Furnaces?

What Are The Key Features Of An Atmosphere Furnace?

What Are The Key Features Of A Split Tube Furnace?

What Are The Key Features Of A Rotary Tube Furnace?

What Are The Key Features Of Multi-zone Tube Furnaces?

What Are The Advantages Of Using A Vacuum Hot Press?

What Are The Advantages Of Using A Tube Furnace?

How Does A Vacuum Furnace Work?

What Are The Features Of A Hot Press Furnace?

How Does A Vacuum Induction Furnace Work?

How Does An Atmosphere Furnace Work?

How Does A Split Tube Furnace Work?

How Does A Rotary Tube Furnace Work?

How Does A Multi-zone Tube Furnace Work?

What Industries Commonly Use Vacuum Hot Press Technology?

What Types Of Tube Furnaces Are Available?

What Are The Advantages Of Using A Vacuum Furnace?

Why Is A Vacuum Environment Used In Hot Press Furnaces?

What Are The Advantages Of Using A Vacuum Induction Furnace?

What Are The Advantages Of Using An Atmosphere Furnace?

What Are The Advantages Of Using A Split Tube Furnace?

What Are The Advantages Of Using A Rotary Tube Furnace?

What Are The Advantages Of Using A Multi-zone Tube Furnace?

What Types Of Materials Can Be Processed In A Vacuum Hot Press?

What Temperature Ranges Can Tube Furnaces Achieve?

What Types Of Materials Can Be Processed In A Vacuum Furnace?

What Materials Are Commonly Processed In Hot Press Furnaces?

What Types Of Vacuum Induction Furnaces Are Available?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

What Temperature Can A Split Tube Furnace Reach?

What Temperature Can A Rotary Tube Furnace Reach?

What Types Of Multi-zone Tube Furnaces Are Available?

What Temperature And Pressure Ranges Can Vacuum Hot Presses Achieve?

Can Tube Furnaces Operate Under Different Atmospheres?

What Is The Difference Between Hot Wall And Cold Wall Vacuum Furnaces?

Why Is Temperature Control Important In Vacuum Induction Furnaces?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

Why Is The Split Design Beneficial In A Tube Furnace?

What Types Of Materials Can Be Processed In A Rotary Tube Furnace?

What Are Some Common Applications Of Vacuum Hot Pressing?

What Makes KINTEK Tube Furnaces Special?

Can Vacuum Furnaces Be Customized For Specific Applications?

What Materials Can Be Processed In A Vacuum Induction Furnace?

How Does The Vacuum Environment Benefit Material Processing?

4.9

out of

5

Incredible precision and speed! This furnace exceeded my expectations. A game-changer for my lab!

4.8

out of

5

Top-notch quality and durability. Worth every penny for the advanced technology it offers.

4.7

out of

5

Fast delivery and easy setup. The furnace performs flawlessly under high temperatures.

4.9

out of

5

The vacuum press feature is revolutionary. Perfect for my research needs. Highly recommend!

4.8

out of

5

Exceptional value for money. The build quality is outstanding, and it heats up in no time.

4.9

out of

5

A masterpiece of engineering. The temperature control is precise, and the results are consistent.

4.7

out of

5

Love the compact design! It’s powerful yet doesn’t take up much space in my workspace.

4.8

out of

5

The vacuum sealing is impeccable. No leaks, no issues. Just pure performance.

4.9

out of

5

This furnace is a beast! Handles everything I throw at it with ease. Super reliable.

4.8

out of

5

The heating speed is unreal. Saves me so much time in my experiments. Brilliant!

4.7

out of

5

User-friendly and efficient. The best investment I’ve made for my lab this year.

4.9

out of

5

The durability is impressive. Even after heavy use, it looks and works like new.

4.8

out of

5

Perfect for high-precision work. The temperature uniformity is spot-on every time.

4.7

out of

5

Arrived earlier than expected! The furnace is a powerhouse—no regrets at all.

4.9

out of

5

Cutting-edge technology at its finest. The vacuum press is a dream come true for my projects.

4.8

out of

5

The build is rock-solid, and the performance is stellar. Exactly what I needed.

4.9

out of

5

Outstanding in every way. Fast, efficient, and built to last. A must-have for professionals.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Vacuum Hot Press Furnace Machine for Lamination and Heating

KINTEK Vacuum Lamination Press: Precision bonding for wafer, thin-film & LCP applications. 500°C max temp, 20-ton pressure, CE certified. Custom solutions available.

Vacuum Hot Press Furnace Machine Heated Vacuum Press

KINTEK Vacuum Hot Pressing Furnace: Precision heating & pressing for superior material density. Customizable up to 2800°C, ideal for metals, ceramics, and composites. Explore advanced features now!

600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

600T Vacuum Induction Hot Press Furnace for precise sintering. Advanced 600T pressure, 2200°C heating, vacuum/atmosphere control. Ideal for research & production.

Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

KINTEK's Vacuum Molybdenum Wire Sintering Furnace excels in high-temperature, high-vacuum processes for sintering, annealing, and material research. Achieve precise 1700°C heating with uniform results. Custom solutions available.

Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

Compact vacuum tungsten wire sintering furnace for labs. Precise, mobile design with superior vacuum integrity. Ideal for advanced material research. Contact us!

9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

Achieve superior ceramic densification with KINTEK's advanced air pressure sintering furnace. High-pressure up to 9MPa, precise 2200℃ control.

Vacuum Heat Treat Sintering and Brazing Furnace

KINTEK Vacuum Brazing Furnaces deliver precision, clean joints with superior temperature control. Customizable for diverse metals, ideal for aerospace, medical, and thermal applications. Get a quote!

Vacuum Heat Treat Furnace with Ceramic Fiber Liner

KINTEK's Vacuum Furnace with Ceramic Fiber Lining offers precise high-temperature processing up to 1700°C, ensuring uniform heat distribution and energy efficiency. Ideal for labs and production.

Molybdenum Vacuum Heat Treat Furnace

High-performance molybdenum vacuum furnace for precise 1400°C heat treatment. Ideal for sintering, brazing, and crystal growth. Durable, efficient, and customizable.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

2200°C Tungsten Vacuum Furnace for high-temperature materials processing. Precise control, superior vacuum, customizable solutions. Ideal for research & industrial applications.

Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

KINTEK's Vacuum Pressure Sintering Furnace offers 2100℃ precision for ceramics, metals, and composites. Customizable, high-performance, and contamination-free. Get a quote now!

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Precision Vacuum Press Furnace for labs: ±1°C accuracy, 1200°C max, customizable solutions. Boost research efficiency today!

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.