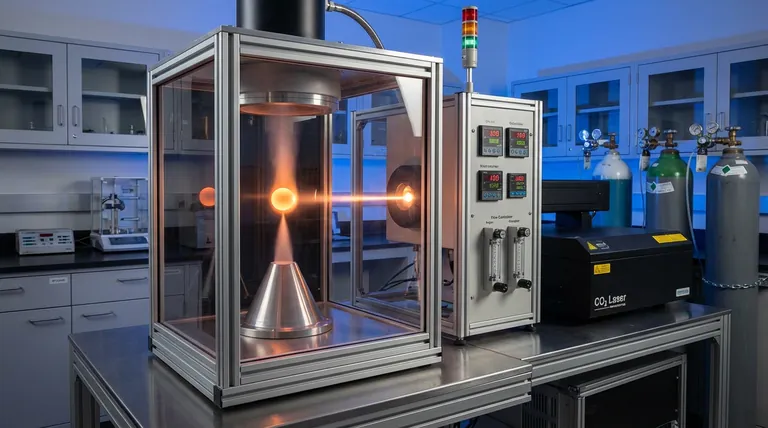

The Aerodynamic Levitation Furnace creates a pristine, contamination-free environment by suspending silicate samples on a gas stream and heating them with a high-power CO2 laser. This technical approach solves the fundamental flaws of traditional heating by removing physical contact with container walls, while simultaneously enabling rapid thermal changes that are impossible with standard equipment.

By eliminating physical contact, this technology resolves the two primary challenges in high-temperature silicate research: preventing chemical contamination from crucibles and achieving the rapid cooling rates necessary to create stable ultra-mafic glass.

Eliminating Contamination Through Levitation

The Problem with Traditional Crucibles

In standard experiments, molten silicates are heated inside a crucible. At high temperatures, the melt often reacts chemically with the container walls. This interaction introduces impurities and alters the chemical composition of the sample, compromising the accuracy of the data.

The Containerless Advantage

Aerodynamic levitation utilizes a gas stream ejected from a conical nozzle to suspend the sample particle in mid-air. Because the sample floats, it never touches a solid surface. This "containerless processing" guarantees that the chemical composition of the melt remains pure and unaffected by reaction vessels.

Achieving Rapid Thermal Cycles

Extreme Heating and Cooling Rates

The system pairs gas suspension with a high-power CO2 laser, allowing for aggressive thermal control. The furnace can achieve heating and cooling rates of approximately 850 degrees Celsius per second.

Accessing Non-Equilibrium States

These rapid rates are technically significant for studying kinetics. Researchers can instantly heat a sample to study high-temperature evaporation kinetics or quench it immediately to freeze its state. This speed captures transient phenomena that slower traditional furnaces would miss.

Unlocking Difficult Material States

Creating Ultra-Mafic Glass

Certain silicate compositions, such as ultra-mafic materials, are notoriously difficult to turn into glass because they crystallize rapidly upon cooling.

The Role of Rapid Quenching

The 850°C/s cooling rate allows researchers to bypass the crystallization phase entirely. By dropping the temperature faster than crystals can form, the system produces uniform, high-quality ultra-mafic glass samples that are essential for geochemical and physical analysis.

Understanding the Trade-offs

Sample Size Constraints

While aerodynamic levitation offers purity, it is generally limited to small sample particles. The physics required to suspend a material on a gas stream restricts the mass and volume of the sample compared to the bulk quantities possible in a crucible.

Operational Complexity

This method introduces variables that do not exist in static heating. The user must balance gas flow dynamics with laser power to maintain stable levitation. This requires more precise calibration and monitoring than simply setting a temperature on a resistive heating furnace.

Making the Right Choice for Your Experiment

To determine if an Aerodynamic Levitation Furnace is the correct tool for your silicate research, consider your specific analytical requirements:

- If your primary focus is absolute chemical purity: Use this furnace to eliminate the risk of reaction between the melt and the crucible walls.

- If your primary focus is capturing amorphous structures: Leverage the 850°C/s cooling rate to produce glass from materials that typically crystallize too quickly.

- If your primary focus is evaporation kinetics: Utilize the rapid heating capabilities to study volatility at high temperatures without the thermal lag of a physical container.

This technology transforms silicate melt experiments from a struggle against contamination into a precise study of material properties.

Summary Table:

| Feature | Traditional Crucible Heating | Aerodynamic Levitation Furnace |

|---|---|---|

| Contact Medium | Physical Crucible Walls | Gas Stream (Containerless) |

| Contamination Risk | High (Wall-Melt Reactions) | Zero (Pristine Environment) |

| Cooling Rate | Slow (Thermal Inertia) | Rapid (~850°C/s) |

| Primary Sample State | Crystalline/Equilibrium | Amorphous/Non-Equilibrium |

| Glass Formation | Difficult for Ultra-Mafic | Optimized for Ultra-Mafic |

| Complexity | Low / Standard | High / Precision Calibration |

Elevate Your Materials Research with KINTEK

Are you struggling with crucible contamination or slow cooling rates in your silicate experiments? At KINTEK, we specialize in providing high-precision thermal solutions tailored to the most demanding scientific needs. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temperature furnaces designed for your unique research goals.

Whether you need to achieve rapid quenching or maintain absolute chemical purity, our engineers are ready to help you find the perfect system. Contact KINTEK today to discuss your custom furnace requirements and ensure the integrity of your next breakthrough.

References

- Célia Dalou, Paolo A. Sossi. Review of experimental and analytical techniques to determine H, C, N, and S solubility and metal–silicate partitioning during planetary differentiation. DOI: 10.1186/s40645-024-00629-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What type of pumping systems are used in high vacuum furnaces? Essential Guide for Clean and Efficient Processing

- Why is the SOM titanium alloy furnace set to 1100°C–1300°C? Optimizing Oxygen-Ion Conductivity

- Why is a vacuum high-temperature furnace necessary for Cu-Cr-Zr-La alloy ingots? Ensure Material Uniformity

- What is the function of a vertical vacuum furnace in the purification of Rubidium Chloride? Achieve High Purity Yields

- What are the selection criteria for vacuum pumps in vacuum furnaces? Optimize for Purity and Efficiency

- What role does a vacuum annealing furnace play in evaluating Ag2S1-xTex phase stability? Map Material Limits Precisely

- What are the limitations of high vacuum furnaces? Understand Costs, Time, and Material Challenges

- Why use a vacuum oven for composite fillers? Protect Material Integrity & Prevent Oxidation