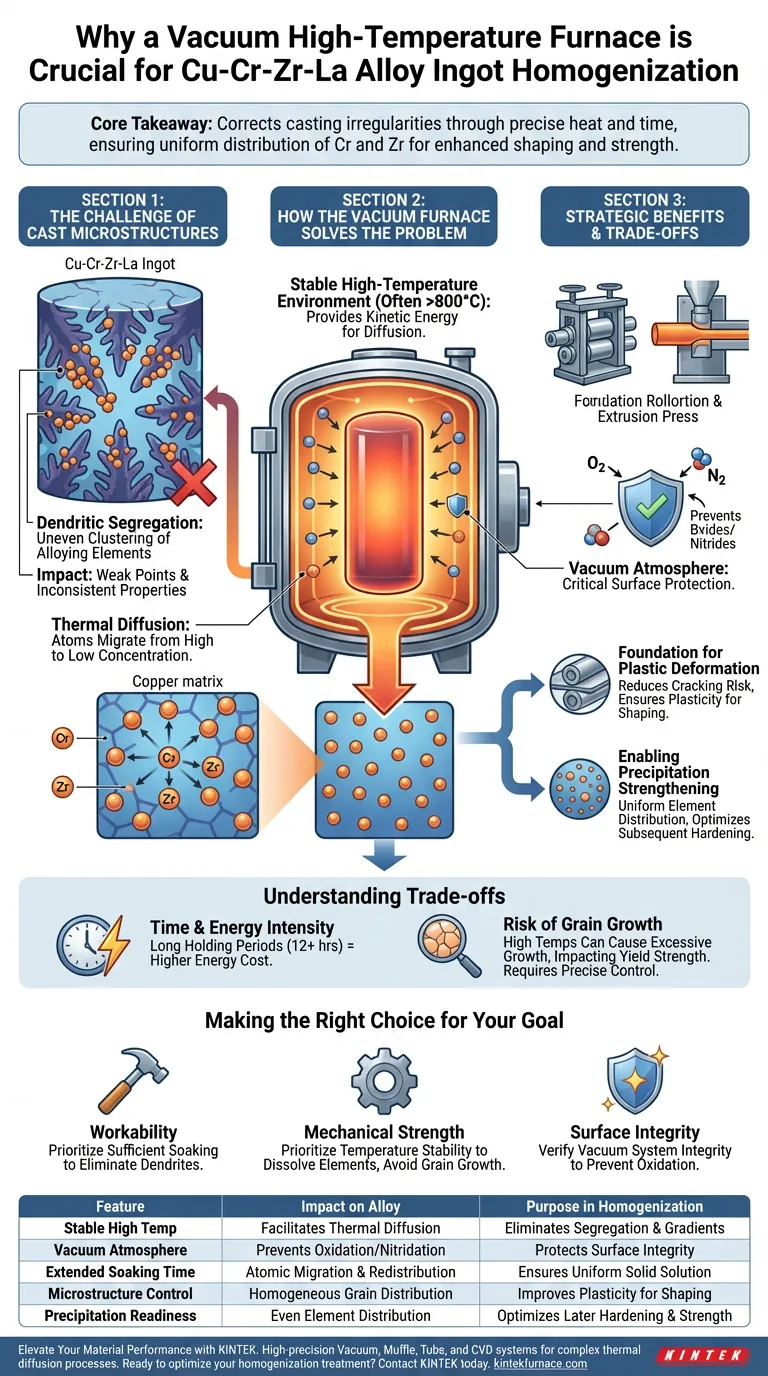

A vacuum high-temperature furnace is essential for treating Cu-Cr-Zr-La ingots because it creates the specific thermodynamic conditions required to correct microstructural irregularities formed during casting. By maintaining a stable, elevated temperature for extended periods, the furnace enables thermal diffusion, which eliminates dendritic segregation and ensures a uniform distribution of alloying elements.

Core Takeaway: Casting inherently creates an uneven distribution of elements (segregation). The vacuum furnace uses precise heat and time to redistribute Chromium and Zirconium atoms evenly throughout the copper matrix, creating the necessary structural uniformity for subsequent shaping and strengthening.

The Challenge of Cast Microstructures

The Problem of Dendritic Segregation

During the initial casting of Cu-Cr-Zr-La alloys, the molten metal cools and solidifies rapidly. This process naturally results in dendritic segregation, where alloying elements cluster unevenly rather than mixing perfectly.

The Impact of Uneven Distribution

Without treatment, elements like Chromium (Cr) and Zirconium (Zr) remain concentrated in specific areas (dendrites) while depleting others. This lack of uniformity creates weak points in the material and makes consistent mechanical properties impossible to achieve.

How the Furnace Solves the Problem

Providing Kinetic Energy for Diffusion

The furnace provides a stable high-temperature environment (often above 800°C) that energizes the atoms within the alloy. This thermal energy increases atomic vibration, giving solute atoms the kinetic power they need to migrate through the copper lattice.

Eliminating Compositional Gradients

Through the mechanism of thermal diffusion, atoms move from areas of high concentration to areas of low concentration. Over an extended holding period, this movement gradually erases the chemical differences caused by segregation, resulting in a homogeneous solid solution.

Protection via Vacuum Environment

While the primary mechanism is thermal, the vacuum atmosphere is critical for protecting the ingot surface. At homogenization temperatures, copper and its alloying elements are highly reactive to oxygen; the vacuum prevents the formation of brittle oxides or nitrides that would degrade the material's surface quality.

Strategic Benefits for Downstream Processing

Foundation for Plastic Deformation

A homogenized microstructure is mechanically uniform, significantly reducing the risk of cracking during physical shaping. This treatment ensures the ingot has the necessary plasticity to undergo processes like extrusion or rolling without failure.

Enabling Precipitation Strengthening

The ultimate strength of Cu-Cr-Zr-La alloys comes from precipitation hardening later in the manufacturing cycle. Homogenization ensures that Cr and Zr are distributed uniformly in the matrix first, allowing them to precipitate evenly and effectively during subsequent aging treatments.

Understanding the Trade-offs

Time and Energy Intensity

Homogenization is not a rapid process; it often requires holding the material at high temperatures for 12 hours or more. This makes it an energy-intensive step that adds to the overall manufacturing cycle time and cost.

Risk of Grain Growth

While high temperatures facilitate diffusion, they can also induce excessive grain growth if not carefully controlled. If the grains become too large, the yield strength of the material may decrease, requiring a balance between sufficient diffusion time and grain size control.

Making the Right Choice for Your Goal

To maximize the quality of your Cu-Cr-Zr-La alloy, align your processing parameters with your specific objectives:

- If your primary focus is Workability: Ensure the soaking time is sufficient to completely eliminate dendritic structures, as any residual segregation can lead to cracking during extrusion.

- If your primary focus is Mechanical Strength: Prioritize precise temperature stability to dissolve alloying elements fully without causing excessive grain growth, setting the stage for optimal precipitation hardening.

- If your primary focus is Surface Integrity: Verify the integrity of the vacuum system to prevent high-temperature oxidation, which eliminates the need for aggressive surface cleaning later.

The vacuum high-temperature furnace transforms a raw, uneven casting into a uniform, high-performance material ready for advanced manufacturing.

Summary Table:

| Feature | Impact on Cu-Cr-Zr-La Alloy | Purpose in Homogenization |

|---|---|---|

| Stable High Temperature | Facilitates thermal diffusion | Eliminates dendritic segregation & chemical gradients |

| Vacuum Atmosphere | Prevents oxidation & nitridation | Protects surface integrity of the copper matrix |

| Extended Soaking Time | Atomic migration & redistribution | Ensures a uniform solid solution throughout the ingot |

| Microstructure Control | Homogeneous grain distribution | Improves plasticity for extrusion and rolling |

| Precipitation Readiness | Even element distribution | Optimizes later hardening and mechanical strength |

Elevate Your Material Performance with KINTEK

Achieve the ultimate structural uniformity and chemical stability for your specialized alloys. Backed by expert R&D and manufacturing, KINTEK offers high-precision Vacuum, Muffle, Tube, and CVD systems designed to master complex thermal diffusion processes. Whether you are processing Cu-Cr-Zr-La ingots or developing next-generation materials, our customizable lab high-temperature furnaces provide the stable environment needed to eliminate segregation and prevent oxidation.

Ready to optimize your homogenization treatment? Contact KINTEK today for a tailored solution.

Visual Guide

References

- Hairui Zhi, Haitao Zhao. Low cycle fatigue behavior of Cu-Cr-Zr-La alloys. DOI: 10.1088/1742-6596/2951/1/012133

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is removing oxygen important in a vacuum furnace? Prevent Oxidation for Superior Metal Quality

- How does a vacuum distillation system function in REE extraction? Master LME Separation with Precision

- What support services are available for custom vacuum furnace users? Ensure Lifelong Performance and Uptime

- What is the purpose of the heat shield in a magnesium vacuum distillation furnace? Ensuring Process Efficiency and Purity

- What are some additional applications of continuous vacuum furnaces? Unlock Advanced Material Processing

- How does vacuum brazing minimize material stress and distortions? Achieve Dimensional Stability for High-Precision Assemblies

- Why is an industrial vacuum drying oven indispensable for battery assembly? Protect Your Battery Life and Safety

- What are the advantages of using a Vacuum Evaporation-Assisted (VEA) reactor? Cut Costs and Boost Synthesis Efficiency