At its core, vacuum brazing minimizes material stress and distortion through exceptionally uniform heating and meticulously controlled cooling rates. This precision thermal management, conducted within a pristine vacuum environment, ensures the entire assembly heats and cools as a single, stable unit, preventing the thermal gradients that cause warping and locked-in stress.

The true advantage of vacuum brazing isn't just preventing new stresses; it's the unique ability to simultaneously join components while actively relieving pre-existing residual stresses from prior manufacturing steps, resulting in a dimensionally stable and metallurgically sound final assembly.

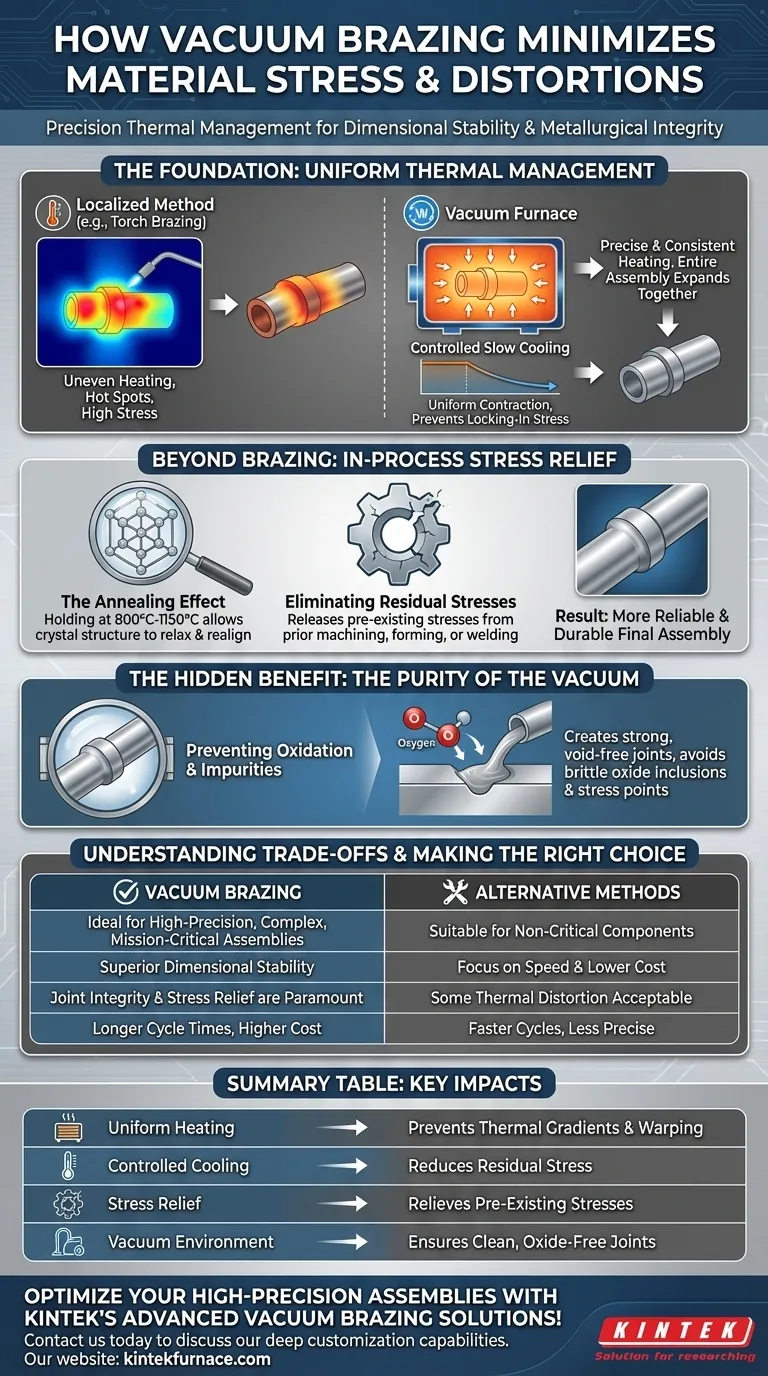

The Foundation: Uniform Thermal Management

The primary cause of stress and distortion in any thermal process is uneven temperature change. Different parts of an assembly expanding or contracting at different rates will inevitably pull and push against each other. Vacuum brazing is designed specifically to counteract this phenomenon.

Precise and Consistent Heating

Unlike localized methods like torch brazing, a vacuum furnace heats the entire component assembly simultaneously. The radiant heat and controlled atmosphere ensure there are no hot spots.

This uniform heating allows the entire structure to expand slowly and predictably, eliminating the internal forces that lead to warping.

The Critical Role of Slow Cooling

Once the brazing filler metal has flowed and solidified, the cooling process is just as critical as the heating. Rapid or uneven cooling is a primary source of residual stress.

Vacuum brazing allows for a programmable, slow cooling ramp. This ensures all sections of the assembly, from thin walls to thick flanges, contract at a near-uniform rate, preserving the part's final shape and dimensions.

Beyond Brazing: In-Process Stress Relief

A significant, often overlooked, benefit of vacuum brazing is that the process itself functions as a stress-relief heat treatment. The assembly doesn't just emerge with a strong joint; it emerges in a more stable state than when it went in.

The Annealing Effect

The process of holding the assembly at a high brazing temperature (typically 800°C to 1150°C) allows the crystal structure of the base materials to relax and realign.

This is effectively a vacuum annealing cycle. It allows the material to release internal stresses that may have been introduced during earlier processes like machining, forming, or welding.

Eliminating Residual Stresses

The result is an assembly that is largely free from the hidden residual stresses that can cause premature failure or dimensional changes over time.

By removing these stresses, vacuum brazing enhances the material's toughness and plasticity, leading to a more reliable and durable final product.

Understanding the Trade-offs

While highly effective, vacuum brazing is not a universal solution. Its precision comes with specific considerations that make it ideal for some applications but less practical for others.

Cycle Time and Cost

The meticulous control over heating and cooling means that vacuum furnace cycles are long, often lasting several hours. This makes the process more expensive and time-consuming than faster methods like torch or induction brazing.

It is best suited for high-value, complex, or mission-critical assemblies where dimensional accuracy is non-negotiable.

Material and Filler Compatibility

The high temperatures and vacuum environment place constraints on material selection. Materials must be able to withstand the brazing temperature without degradation, and they must not "outgas" (release trapped gases), which can disrupt the vacuum.

Furthermore, specific filler metals are required that are compatible with the vacuum process and the base materials being joined.

The Hidden Benefit: The Purity of the Vacuum

The vacuum environment itself plays a crucial, indirect role in preventing stress by ensuring the highest possible joint quality.

Preventing Oxidation and Impurities

Performing the process in a near-perfect vacuum (or a pure inert gas backfill like argon) eliminates oxygen. Without oxygen, the metal surfaces cannot oxidize during heating.

This guarantees that the brazing filler metal flows onto a perfectly clean surface, creating a strong, void-free joint without the brittle oxide inclusions that can act as stress concentration points.

Ensuring Material Integrity

Because there are no combustion by-products, as seen in flame brazing, the process is exceptionally clean. This preserves the inherent chemistry and mechanical properties of the base materials, ensuring the final assembly performs exactly as designed.

Making the Right Choice for Your Assembly

Selecting the right joining process depends entirely on the requirements of your final component.

- If your primary focus is ultimate dimensional stability and joint integrity: Vacuum brazing is the superior choice for complex, high-precision assemblies where preventing distortion and relieving stress are paramount.

- If your primary focus is speed and lower cost for non-critical components: Alternative methods like torch or induction brazing may be more appropriate, provided some degree of thermal distortion is acceptable.

By controlling the entire thermal environment with unmatched precision, vacuum brazing delivers assemblies with superior strength and dimensional fidelity.

Summary Table:

| Key Factor | Impact on Stress/Distortion |

|---|---|

| Uniform Heating | Prevents thermal gradients and warping by heating the entire assembly evenly |

| Controlled Cooling | Reduces residual stress through slow, programmable cooling rates |

| Stress Relief | Relieves pre-existing stresses via annealing effect during brazing |

| Vacuum Environment | Ensures clean, oxide-free joints to avoid stress concentration points |

Optimize your high-precision assemblies with KINTEK's advanced vacuum brazing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom high-temperature furnace systems, including Vacuum & Atmosphere Furnaces, designed to minimize stress and distortions for superior dimensional stability. Contact us today to discuss how our deep customization capabilities can meet your unique experimental requirements and enhance your product reliability.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?