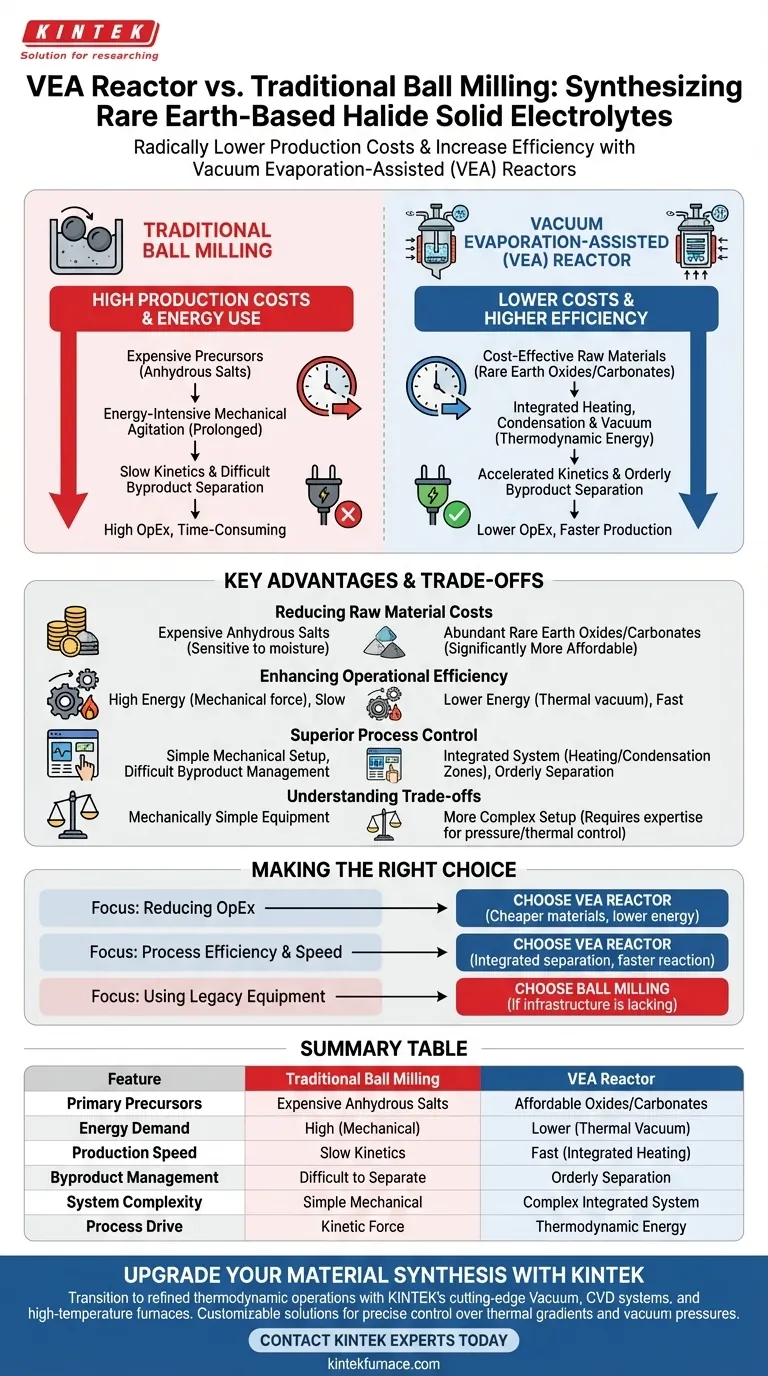

The primary advantage of a Vacuum Evaporation-Assisted (VEA) reactor is its ability to radically lower production costs while increasing synthesis efficiency. By shifting from mechanical force to a thermal vacuum process, you can utilize cost-effective raw materials like rare earth oxides or carbonates, avoiding the need for the expensive anhydrous salt precursors required by traditional ball milling.

Core Takeaway Traditional ball milling is an energy-intensive process that relies on costly, high-purity precursors. In contrast, the VEA reactor integrates heating, condensation, and vacuum systems to enable the direct synthesis of halide electrolytes from cheaper raw materials, ensuring a more efficient process with orderly byproduct separation.

Reducing Raw Material Costs

Moving Away from Expensive Precursors

Traditional mechanical ball milling imposes a strict requirement on input materials. You typically must use anhydrous salt precursors, which are often expensive to procure and difficult to handle due to their sensitivity to moisture.

Utilizing Abundant Alternatives

The VEA reactor eliminates this constraint. It allows for the direct synthesis of halide electrolytes using rare earth oxides or carbonates. These materials are significantly more affordable and readily available than their anhydrous salt counterparts, leading to a substantial reduction in overall raw material costs.

Enhancing Operational Efficiency

Lowering Energy Consumption

Mechanical ball milling is inherently energy-intensive. It relies on prolonged physical agitation to drive chemical reactions, which consumes vast amounts of power over long periods.

Accelerating Production Time

In addition to high energy use, ball milling is time-consuming. The VEA reactor bypasses the slow kinetics of solid-state mechanical grinding. By utilizing integrated heating and vacuum systems, it accelerates the reaction kinetics, significantly shortening the synthesis cycle.

Superior Process Control

Integrated System Design

The VEA reactor is not just a heating vessel; it is a sophisticated system that integrates heating zones, condensation zones, and vacuum systems. This integration allows for precise control over the reaction environment that mechanical milling cannot match.

Orderly Separation of Byproducts

One of the distinct technical advantages of the VEA method is the orderly separation of products and byproducts. The vacuum and condensation mechanisms actively manage the removal of reaction byproducts, yielding a cleaner final product without the extensive post-processing often required after ball milling.

Understanding the Trade-offs

Equipment Complexity

While ball milling is energy-intensive, the equipment itself is mechanically simple. The VEA reactor involves a more complex setup, requiring reliable vacuum pumps, precise temperature controllers, and condensation systems. This requires a higher level of operator expertise to manage the system pressures and thermal gradients effectively.

Thermal Sensitivity

Ball milling is a "cold" or low-heat process driven by friction and impact. The VEA process relies on thermal energy. While this is efficient for many halides, you must ensure that your specific target material and the intermediate phases are stable at the temperatures required for the evaporation and condensation steps.

Making the Right Choice for Your Goal

To determine which synthesis method aligns with your project constraints, consider the following:

- If your primary focus is reducing operational expenditure (OpEx): Choose the VEA reactor, as it utilizes significantly cheaper raw materials (oxides/carbonates) and reduces energy consumption.

- If your primary focus is process efficiency and speed: Choose the VEA reactor for its integrated ability to separate byproducts and shorten reaction times compared to the slow kinetics of milling.

- If your primary focus is using legacy equipment: Adhere to ball milling only if you lack the infrastructure for vacuum-thermal systems and are willing to absorb the higher cost of anhydrous precursors.

By leveraging the VEA reactor, you transition from a brute-force mechanical process to a refined, cost-effective thermodynamic operation.

Summary Table:

| Feature | Traditional Ball Milling | VEA Reactor |

|---|---|---|

| Primary Precursors | Expensive Anhydrous Salts | Affordable Oxides/Carbonates |

| Energy Demand | High (Mechanical Agitation) | Lower (Thermal Vacuum) |

| Production Speed | Slow Kinetics | Fast (Integrated Heating) |

| Byproduct Management | Difficult to Separate | Orderly Separation via Condensation |

| System Complexity | Simple Mechanical | Complex Integrated System |

| Process Drive | Kinetic Force | Thermodynamic Energy |

Upgrade Your Material Synthesis with KINTEK

Transition from energy-intensive mechanical milling to refined thermodynamic operations. Backed by expert R&D and manufacturing, KINTEK offers cutting-edge Vacuum, CVD systems, and high-temperature furnaces designed to handle the complexities of VEA reactor processes. Whether you need customizable solutions for rare earth halide synthesis or specialized lab equipment, our systems ensure precise control over thermal gradients and vacuum pressures.

Ready to reduce your OpEx and accelerate production?

Visual Guide

References

- Zhichao Zeng, Yaping Du. Vacuum evaporation-assisted reaction: sustainable solution for application of rare earth-based halide solid-state electrolytes. DOI: 10.1039/d5sc00003c

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Induction Melting Furnace

People Also Ask

- What are the differences between hot wall and cold wall vacuum furnace designs? Compare for Your High-Temp Needs

- What is the function of a Spark Plasma Sintering (SPS) system in the preparation of porous tungsten gradient precursors?

- What function does a vacuum chamber serve in the inkjet printing process for perovskite thin films? Expert Insights

- What are the typical specifications of vertical vacuum furnaces with gas pressure quenching? Key Specs for High-Temp Processing

- What factors are critical for successful vacuum brazing? Master Joint Strength and Clean Bonds

- How can vacuum furnace chillers reduce operating costs? Boost Efficiency and Cut Hidden Expenses

- What are the key specifications of vacuum carburizing furnaces? Optimize Your Heat Treatment Process

- Why do some nonferrous metals require a vacuum furnace for heat treating? To Prevent Oxidation and Ensure Purity