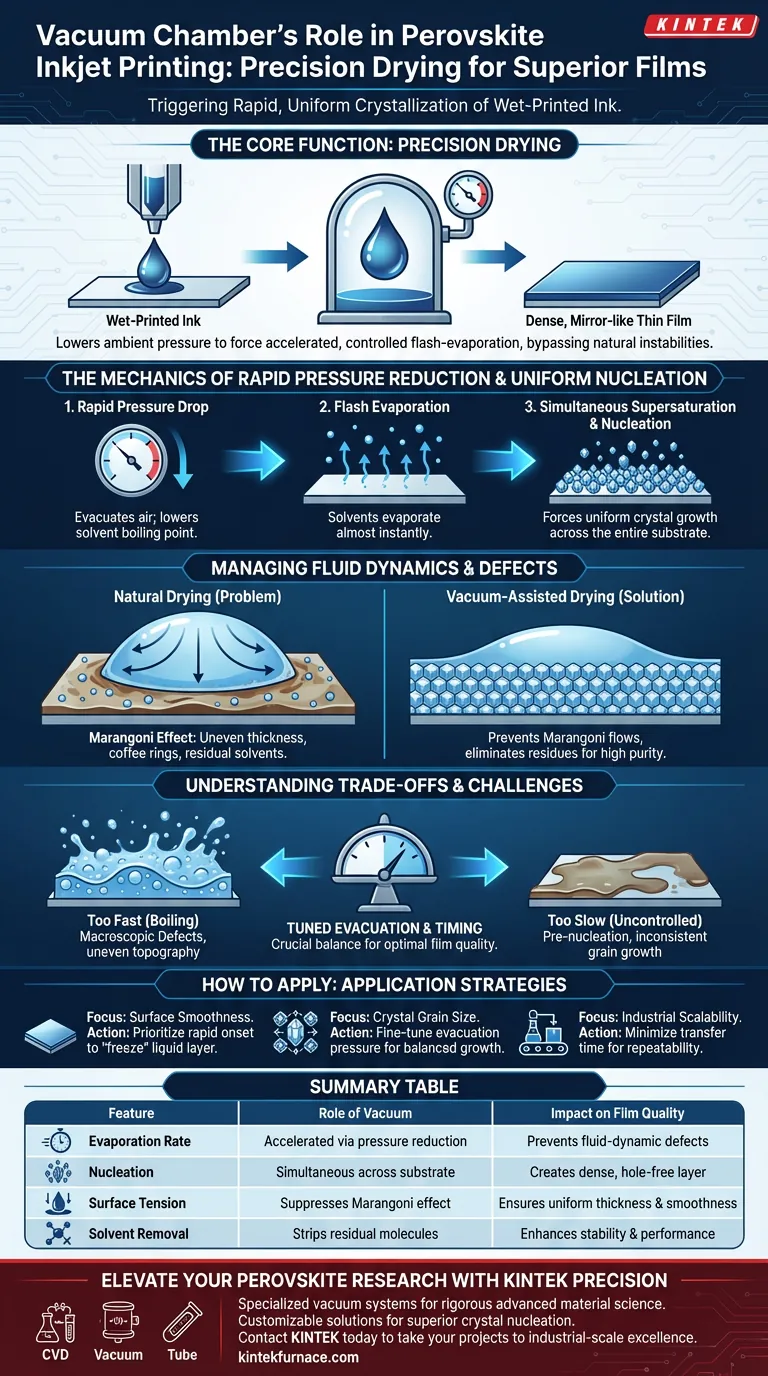

The vacuum chamber acts as a precision drying environment that triggers rapid, uniform crystallization of the wet-printed perovskite ink. By lowering ambient pressure immediately after printing, the system forces the solvent to evaporate at an accelerated and highly controlled rate. This process is essential for bypassing the instabilities of natural drying, resulting in a dense, mirror-like thin film free of structural defects.

The core function of the vacuum chamber is to replace slow, ambient evaporation with a "flash-evaporation" effect that induces simultaneous nucleation across the entire substrate. This method suppresses fluid-dynamic defects and ensures the perovskite crystals form a continuous, hole-free layer.

Accelerating Solvent Evaporation and Nucleation

The Mechanics of Rapid Pressure Reduction

When the substrate is moved into the chamber, the air is quickly evacuated to create a low-pressure environment. This drop in pressure significantly lowers the boiling point of the solvents, causing them to evaporate almost instantly from the wet film. By controlling the speed of evacuation, engineers can dictate exactly when the liquid phase transitions into a solid crystalline structure.

Achieving Uniform Crystal Nucleation

Rapid evaporation forces the perovskite precursors into a state of supersaturation across the entire surface at the same time. This simultaneous "tipping point" leads to uniform nucleation, where crystals grow together in a synchronized manner. Uniform nucleation is the primary reason vacuum-assisted films are denser and more consistent than those dried in open air.

Managing Fluid Dynamics and Surface Defects

Preventing the Marangoni Effect

In slow-drying environments, differences in surface tension cause liquid to flow within the droplet, a phenomenon known as the Marangoni effect. This effect often pushes material toward the edges of a printed area, resulting in uneven thickness and "coffee ring" stains. The vacuum process "locks" the film in place by removing the solvent before these destructive internal flows can occur.

Eliminating Residual Solvents

Standard natural drying often fails to remove all solvent molecules, which can become trapped within the crystal lattice. The vacuum environment effectively strips away these residues, which is critical for the long-term chemical stability of the perovskite. Removing these impurities results in a high-purity film that exhibits better electrical performance in solar cells or LEDs.

Understanding the Trade-offs

Risk of Excessive Evacuation Speeds

If the vacuum is applied too violently, the solvent can reach a "boiling" state that creates bubbles or splashing within the wet film. This can lead to macroscopic defects or uneven topography, defeating the purpose of the vacuum step. The evacuation rate must be carefully tuned to the specific volatility of the ink's solvent system.

Integration and Timing Challenges

The "transfer time" between the inkjet printer and the vacuum chamber is a critical variable that can introduce inconsistency. If the wet film sits in the air too long, uncontrolled natural drying begins, which may lead to pre-nucleation and non-uniform grain growth. Maintaining a strict, automated transition is necessary to ensure every printed film meets the same quality standard.

How to Apply This to Your Project

To achieve the best results with vacuum-assisted inkjet printing, your approach should vary based on your specific performance requirements.

- If your primary focus is surface smoothness: Prioritize the rapid onset of the vacuum to "freeze" the liquid layer before Marangoni flows can distort the surface.

- If your primary focus is crystal grain size: Fine-tune the evacuation pressure to balance the speed of nucleation with the time allowed for crystals to grow into a dense lattice.

- If your primary focus is industrial scalability: Focus on minimizing the transfer time from the print head to the chamber to ensure process repeatability across large substrates.

By mastering the vacuum-assisted drying phase, you transform inkjet printing from a simple deposition method into a precision crystallization technique.

Summary Table:

| Feature | Role of Vacuum in Inkjet Printing | Impact on Film Quality |

|---|---|---|

| Evaporation Rate | Accelerated via rapid pressure reduction | Prevents fluid-dynamic defects like coffee-ring effects |

| Nucleation | Simultaneous across the entire substrate | Creates a dense, continuous, and hole-free crystal layer |

| Surface Tension | Suppresses Marangoni effect | Ensures uniform film thickness and mirror-like smoothness |

| Solvent Removal | Strips residual molecules from crystal lattice | Enhances chemical stability and electrical performance |

Elevate Your Perovskite Research with KINTEK Precision

High-quality perovskite thin films require the perfect balance of deposition and controlled crystallization. At KINTEK, we provide specialized vacuum systems and lab high-temp furnaces—including CVD, Vacuum, and Tube systems—designed to meet the rigorous demands of advanced material science.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to help you eliminate surface defects and achieve superior crystal nucleation. Contact us today to find the ideal solution for your lab and take your thin-film projects from the lab to industrial-scale excellence.

Visual Guide

References

- Azam Khorasani, Mojtaba Abdi‐Jalebi. Opportunities, Challenges, and Strategies for Scalable Deposition of Metal Halide Perovskite Solar Cells and Modules. DOI: 10.1002/aesr.202300275

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How is forced cooling achieved in hot wall vacuum furnaces? Optimize Metallurgical Properties with Precision Cooling

- Why are vacuum ovens and argon gas protection necessary for MXene monoliths? Ensure Density and Chemical Integrity

- What role do laboratory high-temperature furnaces play in the growth of Ni3In2Se2 single crystals? Precision Growth Control

- How does the annealing process in a high-temperature furnace modify MoS2? Optimize Thermoelectric Performance

- What is the specific purpose of using a vacuum high-temperature furnace for powder pre-treatment? Ensure Sharp Interfaces

- What is the primary use of a vacuum hydrogen dual-purpose furnace? Essential for Diamond Synthesis and High-Performance Sintering

- What types of atmospheres can be used in vacuum heat treatment furnaces? Optimize Your Material Properties

- What is the necessity of using a vacuum drying oven for the 70 °C treatment of synthesized TF-COF? Essential Guide