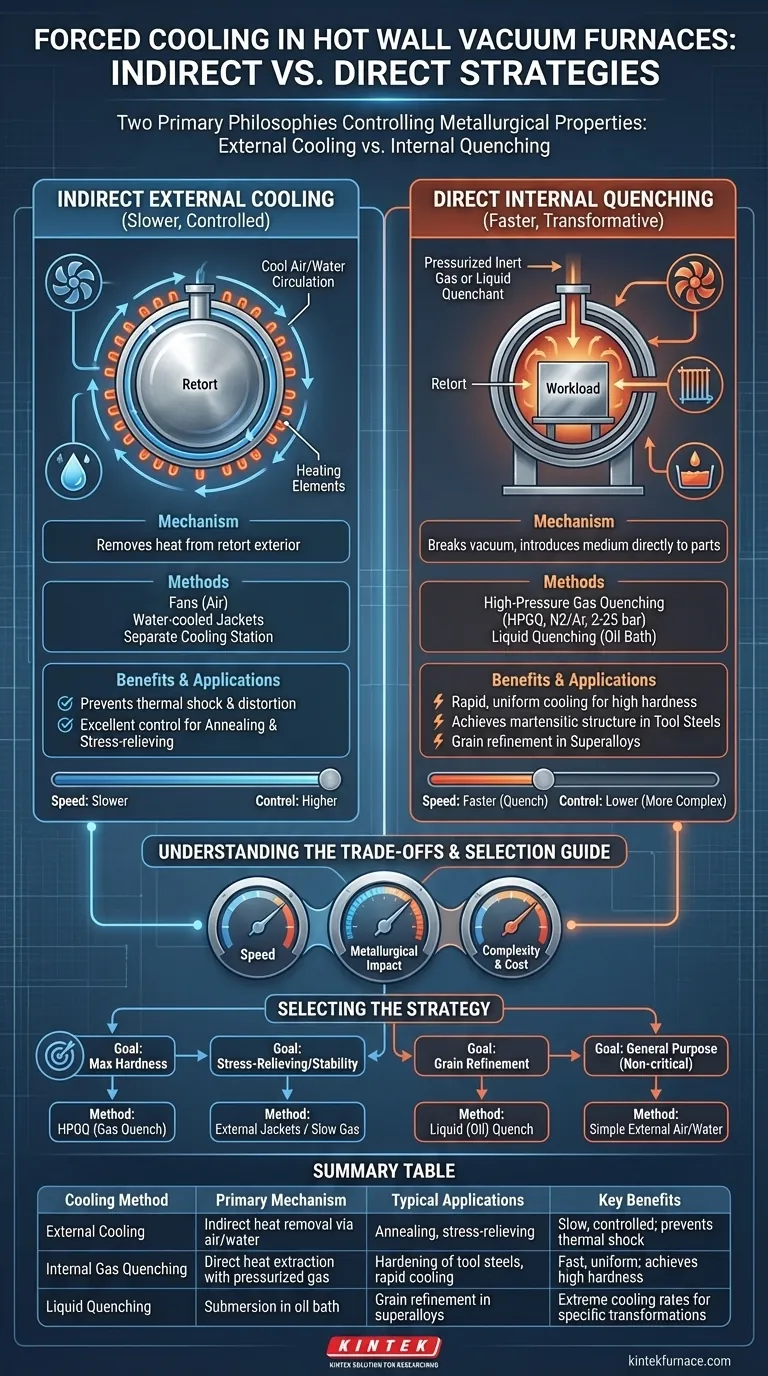

Forced cooling in hot wall vacuum furnaces is achieved through two primary strategies: indirect external cooling of the sealed process chamber (the retort) or direct internal quenching of the workload. External methods involve circulating air or water around the outside of the retort, while internal methods introduce a pressurized inert gas or a liquid quenchant directly to the heated parts to extract heat rapidly.

The choice of a cooling method is not merely a question of speed; it is a critical process variable that directly controls the final metallurgical properties of the material. The fundamental decision is between the slower, simpler control of external cooling and the rapid, transformative impact of internal quenching.

The Two Cooling Philosophies: External vs. Internal

The design of a hot wall furnace, where the heating elements are outside the sealed retort, dictates the possible cooling strategies. The retort contains the vacuum or controlled atmosphere and must be cooled along with the parts inside it.

External Cooling: Indirect Heat Removal

External cooling acts on the outside of the retort, removing heat indirectly and more slowly. This is often sufficient for processes that do not require rapid quenching.

Common methods include circulating cool air with fans around the retort, using a water-cooled jacket that envelops the retort, or physically removing the hot retort from the furnace insulation to a separate cooling station. An advanced design uses an extended retort with a dedicated water-cooled section where the workload can be moved after heating.

Internal Quenching: Direct Heat Removal

Internal quenching is a much faster and more aggressive method that involves breaking the vacuum and introducing a cooling medium directly into the retort. This provides more direct and rapid heat extraction from the parts themselves.

The most common method is inert gas quenching, where gases like nitrogen or argon are injected under pressure. The gas is circulated by a powerful fan through the hot workload, absorbing heat, and then passed through a water-cooled heat exchanger before being recirculated. This closed-loop cycle continues until the desired part temperature is reached.

A Deeper Look at Key Cooling Methods

Each cooling method offers a different level of speed and control, making it suitable for specific materials and desired outcomes.

High-Pressure Gas Quenching (HPGQ)

HPGQ is the dominant method for processes requiring rapid, controlled cooling to achieve specific material hardness.

It uses inert gas, typically nitrogen or argon, at pressures ranging from 2 to 25 bar (approximately 2 to 25 times atmospheric pressure). The high pressure increases the gas's density and heat capacity, allowing it to remove heat much more effectively. Advanced systems use strategically placed nozzles, often optimized with computational fluid dynamics (CFD), to ensure the high-velocity gas cools the entire workload uniformly.

External Cooling Jackets and Fans

This approach represents the simplest form of forced cooling. It is fundamentally a convective cooling process applied to the retort's exterior.

While slower than gas quenching, it offers excellent control for processes like annealing or stress-relieving, where a slow, steady temperature decrease is required to prevent part distortion or cracking. For example, it is the preferred method for stress-relief annealing of titanium components.

Liquid Quenching (Oil)

For the most extreme cooling rates, some specialized vacuum furnaces are equipped for oil quenching. This is an internal quenching method where parts are submerged in a cool oil bath.

This process is used to achieve specific metallurgical transformations, such as refining the grain structure in nickel-based superalloys. Due to the risk of contamination and the complexity of integrating a liquid bath into a vacuum system, it is less common than gas quenching but essential for certain high-performance alloys.

Understanding the Trade-offs

Choosing a cooling system involves balancing metallurgical requirements against operational complexity and cost.

Speed vs. Control

Internal quenching (gas or oil) is significantly faster and is classified as a "quench" because it is rapid enough to cause phase transformations in steel and other alloys.

External cooling is inherently slower. However, its slower rate provides a higher degree of control, which is critical for preventing thermal shock and ensuring dimensional stability in sensitive parts.

Metallurgical Impact

The cooling rate directly determines the final microstructure of the material. A fast quench, like HPGQ, is necessary to achieve a fully hardened martensitic structure in tool steels.

Conversely, a slow, controlled cool-down is required for annealing, which softens the material and relieves internal stresses. The wrong cooling rate can either fail to achieve the desired properties or ruin the component.

System Complexity and Cost

External cooling systems are mechanically simple, reliable, and cost-effective.

Internal HPGQ systems are far more complex. They require a pressure-rated vessel, a powerful (and often vacuum-rated) motor and fan, a large internal heat exchanger, and sophisticated gas handling controls. This adds significant cost and maintenance complexity to the furnace.

Selecting the Right Cooling Strategy

The optimal cooling method is dictated entirely by the material being processed and the final properties you need to achieve.

- If your primary focus is achieving maximum hardness in tool or die steels: High-Pressure Gas Quenching (HPGQ) is essential for its rapid and uniform cooling capability.

- If your primary focus is stress-relieving sensitive or complex components: A controlled, slow cool-down using external jackets or low-pressure inert gas backfilling is the correct approach to ensure stability.

- If your primary focus is refining the grain structure in specialty alloys: Rapid oil quenching provides the extreme cooling rates needed for these specific metallurgical transformations.

- If your primary focus is general-purpose heat treating with non-critical cooling rates: Simpler and more cost-effective external air or water cooling systems are perfectly sufficient.

Ultimately, understanding these methods empowers you to move beyond simply cooling parts and begin precisely engineering their final material properties.

Summary Table:

| Cooling Method | Primary Mechanism | Typical Applications | Key Benefits |

|---|---|---|---|

| External Cooling | Indirect heat removal via air/water circulation | Annealing, stress-relieving | Slow, controlled cooling; prevents thermal shock |

| Internal Gas Quenching | Direct heat extraction with pressurized inert gas | Hardening of tool steels, rapid cooling | Fast, uniform cooling; achieves high hardness |

| Liquid Quenching | Submersion in oil bath | Grain refinement in superalloys | Extreme cooling rates for specific transformations |

Ready to enhance your laboratory's heat treatment processes with tailored cooling solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering optimized metallurgical outcomes. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties