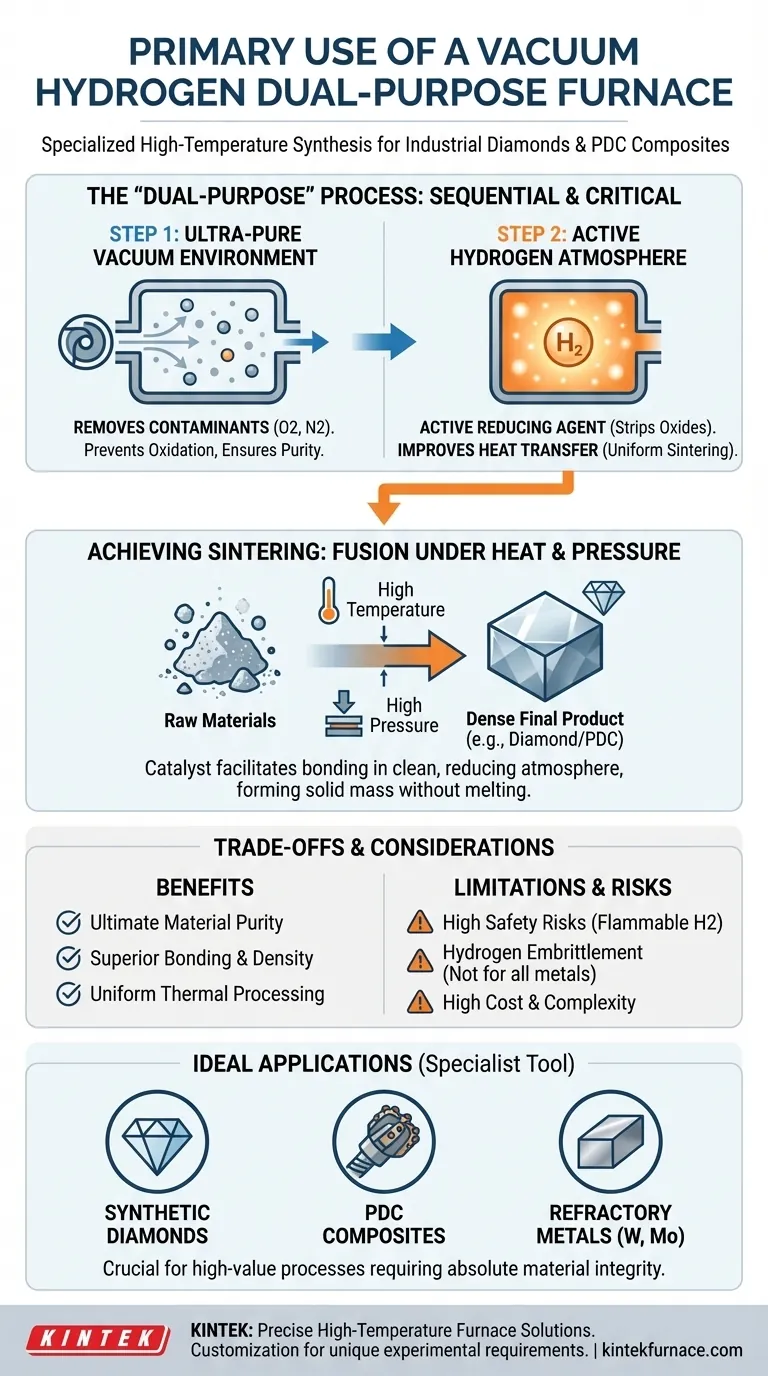

At its core, a vacuum hydrogen dual-purpose furnace is a highly specialized tool designed primarily for the high-temperature, high-pressure synthesis of industrial diamonds and polycrystalline diamond compact (PDC) composite sheets. It achieves this by first creating an ultra-clean vacuum to remove contaminants and then introducing a controlled hydrogen atmosphere to facilitate the sintering process.

The furnace's "dual-purpose" nature is its defining feature. It leverages a vacuum to achieve ultimate purity and a hydrogen atmosphere to actively assist in the chemical and physical bonding of materials, a combination essential for manufacturing advanced composites and synthetic materials.

Deconstructing the "Dual-Purpose" Technology

To understand why this furnace is critical for applications like diamond synthesis, you must understand the distinct roles of its two operating environments: vacuum and hydrogen. They are not interchangeable; they are sequential steps in a sophisticated process.

The Role of the Vacuum: Creating an Ultra-Pure Environment

The initial step in any process is to pull a deep vacuum within the furnace chamber. This removes virtually all atmospheric gases, especially oxygen and nitrogen.

This is not a passive step. Removing these reactive gases is crucial to prevent the oxidation and contamination of the raw materials, typically fine powders. Any oxidation on the surface of the powder particles can inhibit proper bonding, leading to a weak or flawed final product.

The Role of Hydrogen: An Active Processing Atmosphere

Once the chamber is purified by the vacuum, high-purity hydrogen gas is introduced. The hydrogen serves two critical functions that a vacuum alone cannot.

First, hydrogen acts as a powerful reducing agent. It actively strips away any residual surface oxides from the powder particles, creating exceptionally clean surfaces that are ready to fuse together.

Second, it provides a medium for uniform heat transfer. In a pure vacuum, heat transfer is limited to radiation, which can be non-uniform. The hydrogen gas improves thermal conduction, ensuring the entire workpiece reaches and maintains the precise target temperature required for sintering.

How Sintering Is Achieved

Sintering is the process of compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction.

In this furnace, a catalyst metal (like cobalt) is often mixed with diamond or tungsten carbide powder. Under immense heat and pressure, and in the clean, reducing hydrogen atmosphere, the catalyst facilitates the fusing of the powder particles into a dense, solid, and incredibly hard final product.

Understanding the Trade-offs and Limitations

While powerful, this technology is not a universal solution. Its specificity comes with significant operational considerations.

Inherent Safety Risks

Hydrogen is a highly flammable and explosive gas. Operating a vacuum hydrogen furnace requires stringent safety protocols, specialized facility infrastructure for gas handling, and highly trained personnel to mitigate the inherent risks.

Material Compatibility and Embrittlement

The hydrogen atmosphere that is so beneficial for some materials can be destructive to others. Certain metals, including many types of steel, can suffer from hydrogen embrittlement, where hydrogen atoms diffuse into the metal and significantly reduce its ductility and strength. This makes the furnace unsuitable for general-purpose heat treatment of these alloys.

High Cost and Complexity

These are not simple machines. Vacuum hydrogen furnaces represent a significant capital investment and have high operating costs due to the need for high-purity hydrogen, complex control systems, and robust safety measures. Their use is justified only for high-value manufacturing processes where absolute material integrity is non-negotiable.

Applying This to Your Process

Choosing the right thermal processing technology depends entirely on your material and your final goal. This furnace is a specialist tool, not a generalist.

- If your primary focus is producing synthetic diamonds or PDC composites: This furnace is the industry-standard technology required to achieve the necessary purity and sintering quality.

- If your primary focus is sintering refractory metals like tungsten or molybdenum: The combination of a vacuum for outgassing and a hydrogen atmosphere for deoxidation is critical for achieving a fully dense, high-performance final part.

- If your primary focus is general heat treating or brazing common steels: A simpler and more cost-effective vacuum-only furnace is the correct choice to avoid the risk of hydrogen embrittlement.

Ultimately, understanding the distinct roles of vacuum and hydrogen empowers you to select the precise atmospheric condition your material needs to succeed.

Summary Table:

| Feature | Role in Process | Benefit |

|---|---|---|

| Vacuum Environment | Removes contaminants like oxygen | Prevents oxidation, ensures material purity |

| Hydrogen Atmosphere | Acts as reducing agent and heat transfer medium | Facilitates sintering, improves bonding uniformity |

| Dual-Purpose Operation | Sequential vacuum and hydrogen steps | Enables high-purity synthesis of diamonds and composites |

| Safety Considerations | Requires strict protocols for hydrogen handling | Mitigates risks of flammability and explosions |

Unlock the Power of Precision with KINTEK's High-Temperature Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. If you're working on synthetic diamond production, sintering refractory metals, or other high-value processes, our vacuum hydrogen dual-purpose furnaces can deliver the purity and performance you need. Contact us today to discuss how we can tailor a solution for your specific challenges and enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios