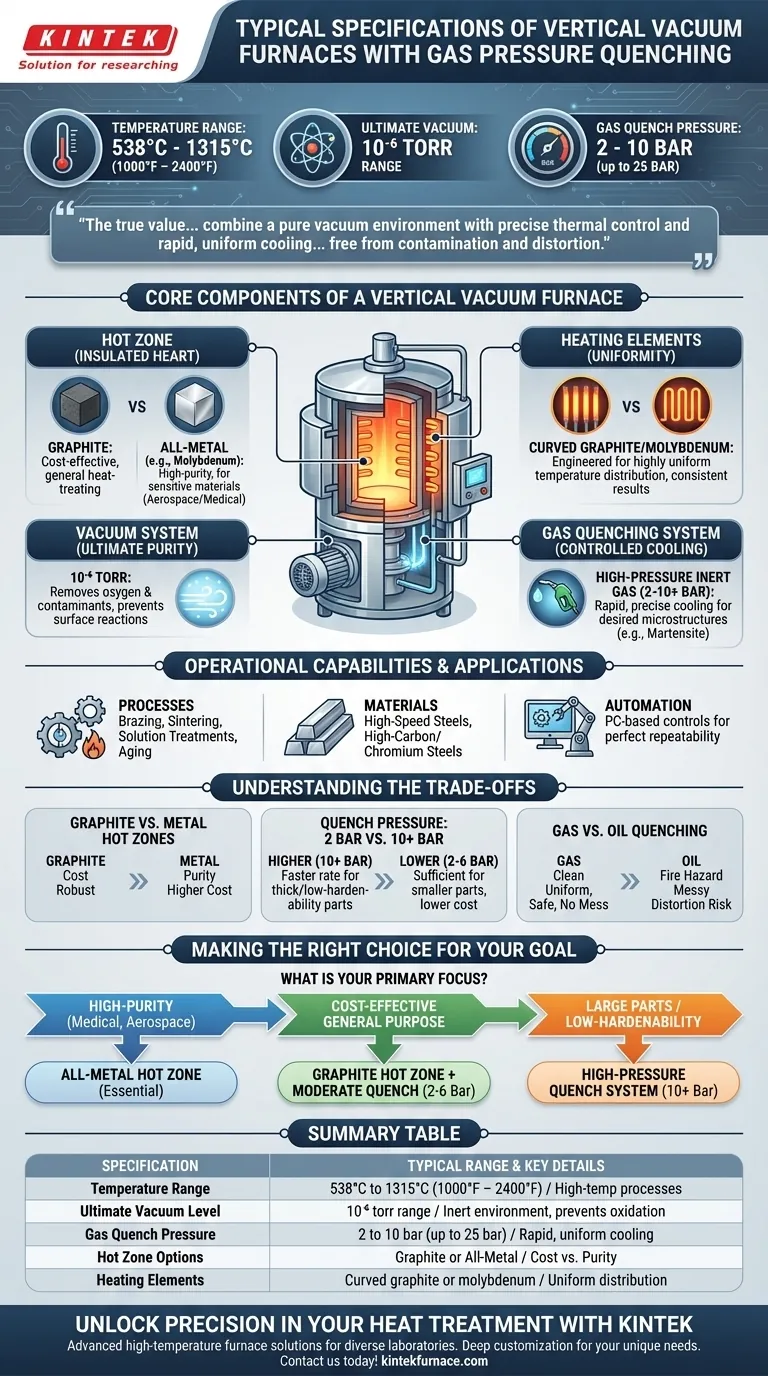

In short, a vertical vacuum furnace with gas pressure quenching is defined by its ability to operate at high temperatures and high vacuum levels, followed by rapid cooling with pressurized inert gas. Key specifications typically include a temperature range of 538°C to 1315°C (1000°F – 2400°F), an ultimate vacuum level in the 10⁻⁶ torr range, and selectable gas quench pressures from 2 to 10 bar.

The true value of these furnaces is not found in any single specification, but in how they combine a pure vacuum environment with precise thermal control and rapid, uniform cooling. This synergy enables the processing of advanced materials to meet exacting quality standards, free from the contamination and distortion common in older methods.

The Core Components of a Vertical Vacuum Furnace

To understand what these furnaces can achieve, you must first understand the function of their core components. Each element plays a critical role in controlling the material's environment and final properties.

The Hot Zone: Graphite vs. All-Metal

The hot zone is the insulated, high-temperature heart of the furnace. The choice of material is a critical decision.

All-graphite hot zones are cost-effective and suitable for a wide range of general heat-treating processes.

All-metal hot zones, typically made of molybdenum, are used for high-purity applications where carbon contamination from graphite would be detrimental to the final product, such as in medical or aerospace components.

Heating Elements: Power and Uniformity

Heating is provided by curved graphite or molybdenum elements. Their design is engineered to deliver highly uniform temperature distribution throughout the workload.

This uniformity is essential for ensuring that every part in a batch, regardless of its position, receives the exact same thermal cycle, leading to consistent and predictable results.

The Vacuum System: Achieving Ultimate Purity

These furnaces operate at an ultimate vacuum in the 10⁻⁶ torr range. Reaching this level of vacuum is not just about removing air; it is about creating a chemically inert environment.

By removing oxygen and other atmospheric contaminants, the vacuum system prevents surface reactions like oxidation and decarburization, ensuring the material's integrity is preserved throughout the high-temperature process.

The Gas Quenching System: Controlled Cooling

After heating, the material is cooled rapidly using high-pressure inert gas, with pressures typically ranging from 2 to 10 bar, though some systems can reach 25 bar.

This high-pressure gas quench is a clean and precisely controlled cooling method. It allows operators to achieve the rapid cooling rates necessary to lock in desired microstructures, such as martensite in steel, which confers hardness and strength.

Operational Capabilities and Applications

The specifications directly translate into a set of highly controlled operational capabilities, making these furnaces ideal for demanding applications.

Suitable Processes

The wide temperature range and controlled environment enable a variety of thermal processes, including high-temperature brazing, sintering of powder metals, solution treatments, and aging.

Suitable Materials

These furnaces are particularly effective for materials that require precise thermal management, such as high-speed steels and high-carbon or high-chromium steels. These materials possess low critical cooling rates, making the controlled gas quench ideal for achieving full hardness.

Automation and Repeatability

Modern furnaces feature PC-based, fully automated controls. This removes process variability and ensures every cycle is run with perfect repeatability, a requirement for industries with strict quality standards.

Understanding the Trade-offs

Selecting the right furnace configuration involves balancing performance needs with practical constraints.

Graphite vs. Metal Hot Zones

The primary trade-off is between cost and purity. A graphite hot zone is a robust, economical choice for most applications. However, for processing reactive or sensitive materials, an all-metal hot zone is mandatory despite its higher cost to avoid carbon contamination.

Quench Pressure: 2 Bar vs. 10+ Bar

Higher quench pressure creates a faster cooling rate. This is critical for achieving hardness in thick material cross-sections or alloys with low hardenability.

Lower pressures (2-6 bar) are often sufficient for smaller parts or materials that harden more easily. Using lower pressure when possible reduces inert gas consumption and operational costs.

Gas vs. Oil Quenching

Gas quenching is a modern, clean alternative to traditional oil quenching. It eliminates fire hazards, messy part cleanup, and the environmental disposal concerns associated with oil. Furthermore, gas provides a more uniform quench, significantly reducing the risk of part distortion.

Making the Right Choice for Your Goal

Your choice of furnace specifications should be driven by your end-product requirements.

- If your primary focus is high-purity processing (e.g., medical, aerospace): An all-metal hot zone is essential to prevent carbon contamination and ensure material integrity.

- If your primary focus is cost-effective, general-purpose heat treatment: A graphite hot zone with a moderate quench pressure (2-6 bar) will provide an excellent balance of performance and economy.

- If your primary focus is processing large parts or low-hardenability alloys: A high-pressure quench system (10 bar or higher) is necessary to achieve the required cooling rates and material properties.

Ultimately, understanding these specifications allows you to precisely match the furnace's capabilities to your specific material and quality demands.

Summary Table:

| Specification | Typical Range | Key Details |

|---|---|---|

| Temperature Range | 538°C to 1315°C (1000°F – 2400°F) | Enables high-temperature processes like brazing and sintering |

| Ultimate Vacuum Level | 10⁻⁶ torr range | Creates inert environment to prevent oxidation and contamination |

| Gas Quench Pressure | 2 to 10 bar (up to 25 bar in some systems) | Allows rapid, uniform cooling for desired microstructures |

| Hot Zone Options | Graphite or All-Metal | Graphite for cost-effectiveness, All-Metal for high-purity applications |

| Heating Elements | Curved graphite or molybdenum | Ensures uniform temperature distribution for consistent results |

Unlock Precision in Your Heat Treatment with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our vertical vacuum furnaces with gas pressure quenching are designed to meet your exact needs, whether for high-purity applications in aerospace or cost-effective general heat treatment. With products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, we offer strong deep customization to precisely match your unique experimental requirements.

Contact us today to discuss how our tailored solutions can enhance your material processing efficiency and quality—Get in touch now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment