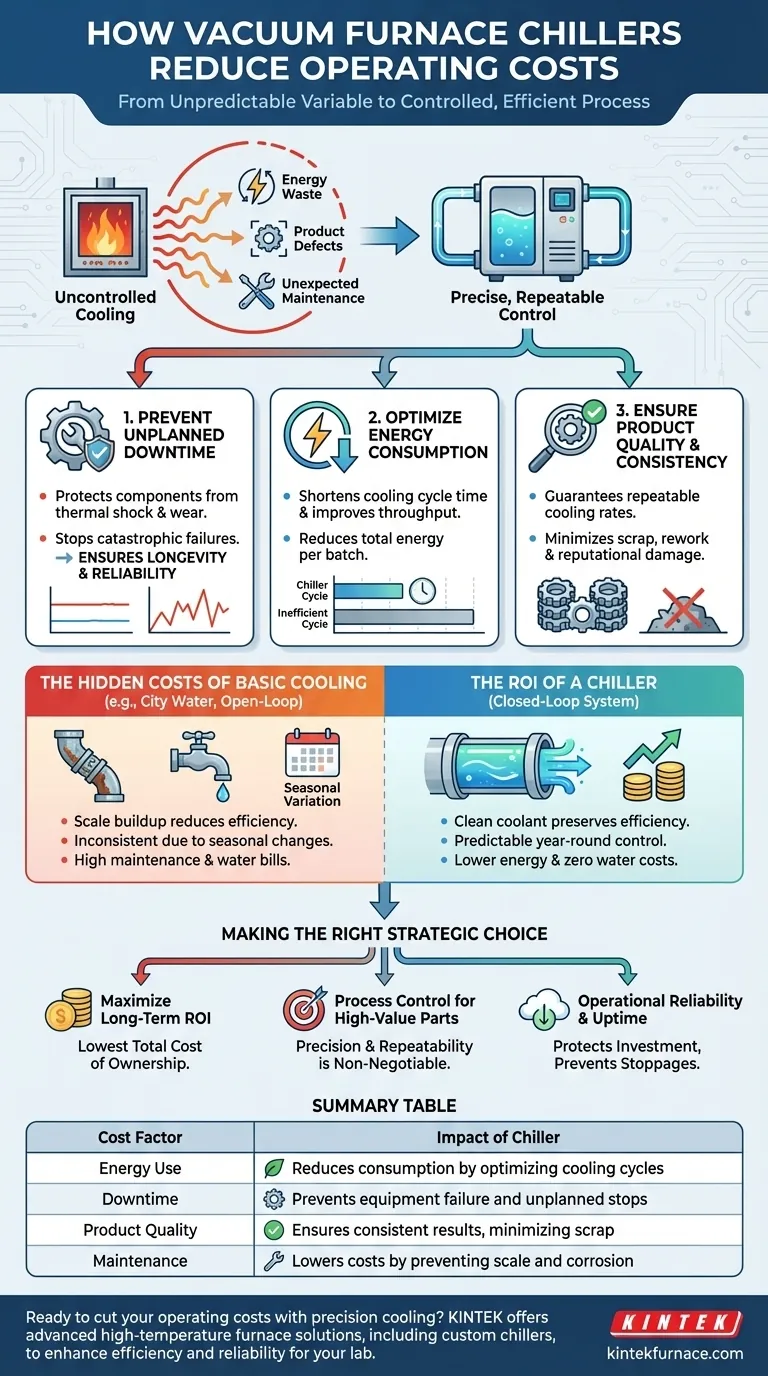

In short, a dedicated vacuum furnace chiller reduces operating costs by transforming cooling from an unpredictable variable into a controlled, efficient process. This directly prevents expensive equipment downtime, lowers energy consumption by optimizing the cooling cycle, and minimizes process variations that lead to scrapped products.

The core issue isn't just about cooling; it's about control. Uncontrolled cooling introduces risk and inefficiency that quietly inflates operating costs through energy waste, product defects, and unexpected maintenance. A chiller mitigates these risks by providing precise, repeatable temperature control.

The Financial Impact of Precision Cooling

A vacuum furnace's performance relies on both efficient heating and efficient cooling. While the furnace's insulation and controls manage heat, the chiller is responsible for removing it predictably. Neglecting the cooling phase creates hidden operational costs.

Preventing Unplanned Downtime

Temperature fluctuations place significant stress on critical furnace components. Inconsistent or inadequate cooling can lead to premature wear and catastrophic failure of the furnace itself, resulting in costly emergency repairs and lost production time.

A chiller delivers a stable supply of cooling fluid at a consistent temperature and pressure, protecting the equipment from thermal shock and ensuring its longevity.

Optimizing Energy Consumption

A furnace and its cooling system operate in a cycle. An inefficient cooling process, where it takes too long to reach the target temperature, extends the overall cycle time. This forces the entire system to run longer, consuming more energy for every batch.

By rapidly and efficiently removing heat, a chiller shortens the cooling portion of the cycle. This improves the furnace's overall throughput and directly reduces its total energy consumption per cycle.

Ensuring Product Quality and Consistency

The cooling rate is a critical parameter in heat treatment, directly influencing the final metallurgical properties of the product. Inconsistent cooling from sources like city water or open-loop towers leads to process variation.

This variation can result in parts that don't meet specifications, leading to expensive scrap, rework, and potential damage to your reputation. A chiller guarantees repeatable cooling cycles, ensuring every batch meets the exact same quality standard.

Understanding the Trade-offs: Chiller vs. Basic Cooling

While a dedicated chiller has an upfront cost, evaluating it against seemingly "cheaper" alternatives reveals its long-term value.

The Hidden Costs of Alternative Cooling

Solutions like using untreated city water or an open-loop cooling tower introduce significant operational problems. Minerals in city water create scale buildup within the furnace's cooling passages, acting as an insulator and drastically reducing cooling efficiency over time. This leads to higher energy bills and expensive, difficult descaling maintenance.

Furthermore, these methods are subject to seasonal temperature variations, making it impossible to maintain a consistent process year-round without constant adjustment and oversight.

The Return on Investment of a Chiller

A closed-loop chiller system uses a clean, treated coolant that prevents scale and corrosion, preserving the furnace's efficiency for its entire lifespan. The initial investment in the chiller is systematically paid back through lower energy bills, zero water consumption costs, reduced scrap rates, and the avoidance of costly downtime and descaling maintenance.

Making the Right Choice for Your Operation

Choosing the right cooling system is a strategic decision that directly impacts your bottom line.

- If your primary focus is maximizing long-term ROI: A dedicated chiller offers the lowest total cost of ownership by systematically reducing energy, water, maintenance, and scrap costs.

- If your primary focus is process control for high-value parts: The precision and repeatability of a chiller are non-negotiable for guaranteeing product quality and consistency.

- If your primary focus is operational reliability and uptime: A chiller protects your furnace investment and prevents the costly production stoppages associated with equipment failure or inconsistent cooling.

By investing in controlled cooling, you are taking direct control over your process efficiency, product quality, and operational costs.

Summary Table:

| Cost Factor | Impact of Chiller |

|---|---|

| Energy Use | Reduces consumption by optimizing cooling cycles |

| Downtime | Prevents equipment failure and unplanned stops |

| Product Quality | Ensures consistent results, minimizing scrap |

| Maintenance | Lowers costs by preventing scale and corrosion |

Ready to cut your operating costs with precision cooling? KINTEK offers advanced high-temperature furnace solutions, including custom chillers, to enhance efficiency and reliability for your lab. Contact us today to discuss how we can tailor our products to your needs!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance