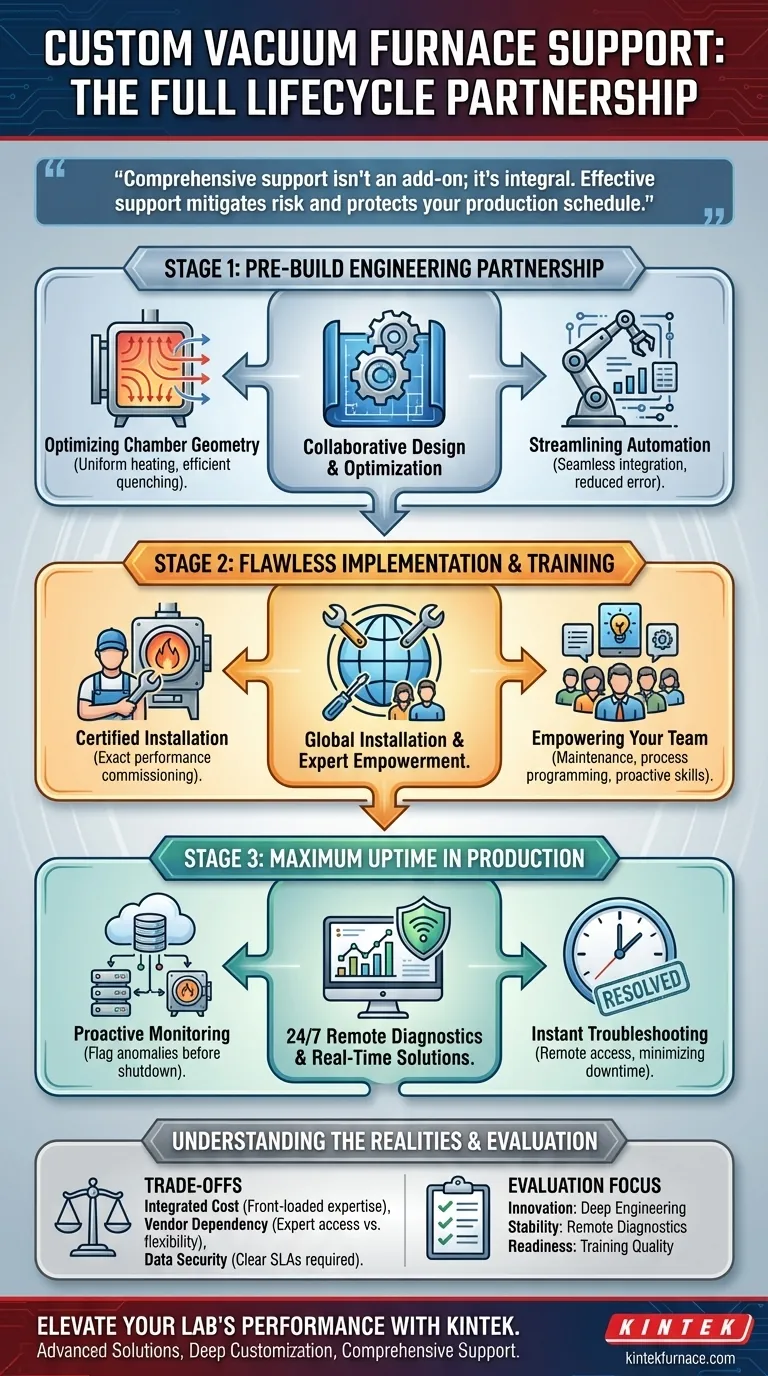

For a custom vacuum furnace, comprehensive support services are not an add-on; they are integral to the investment. The primary services available span the entire lifecycle of the equipment, including collaborative design to optimize the system before it's built, global installation and hands-on training by certified technicians, and 24/7 remote diagnostics to ensure continuous production with minimal downtime.

The decision to acquire a custom vacuum furnace hinges less on the hardware itself and more on the quality of the support partnership. Effective support mitigates risk at every stage, from initial concept to daily operation, ensuring the equipment delivers on its promised value and protects your production schedule.

Stage 1: The Pre-Build Engineering Partnership

The most critical support happens before a single piece of metal is cut. This initial phase is a collaborative effort to ensure the furnace is perfectly tailored to your specific process and operational needs, preventing costly downstream modifications.

Optimizing Chamber Geometry

The chamber's design directly impacts product quality and throughput. A collaborative design process ensures the geometry provides uniform heating, efficient gas or oil quenching, and can accommodate your specific part sizes and configurations. This is foundational for achieving consistent, repeatable metallurgical results.

Streamlining Automation and Workflow

Modern furnaces are complex automated systems. Support at this stage involves mapping out your entire workflow to integrate the furnace seamlessly into your production line. This reduces the need for manual intervention, minimizes the chance of human error, and ensures the furnace communicates effectively with other factory systems.

Stage 2: Flawless Implementation and Training

Once the furnace is built, the support focus shifts to bringing it online correctly and empowering your team to operate it with confidence.

Global Installation by Certified Experts

A custom furnace requires specialized installation. This service is performed by technicians certified by the manufacturer who understand the system's unique mechanical, electrical, and software intricacies. This guarantees the furnace is commissioned to exact performance and safety specifications from day one.

Empowering Your Team Through Training

Effective training goes beyond basic operation. A robust training program covers routine maintenance, process programming, and—most importantly—how to recognize early warning signs of potential issues. This knowledge empowers your staff to be proactive, maximizing uptime and operational self-sufficiency.

Stage 3: Ensuring Maximum Uptime in Production

After commissioning, support services transform into a safety net that protects your ongoing production and revenue.

The Power of 24/7 Remote Diagnostics

This service connects your furnace directly to a team of off-site experts. By continuously monitoring critical operational data, the system can automatically flag anomalies or performance deviations before they escalate into a shutdown. It is the most effective tool for proactive maintenance.

Real-Time Troubleshooting for Uninterrupted Production

When an issue does arise, remote diagnostics allow technicians to access the furnace’s control system to diagnose the problem immediately. Many software or parameter-related faults can be resolved in minutes, avoiding the costly delay of waiting for a technician to travel to your site. This is your insurance policy against extended downtime.

Understanding the Trade-offs

While comprehensive support is invaluable, it's important to approach it with a clear understanding of the associated realities.

The "Free" Design Component

The collaborative design process is rarely free; its cost is integrated into the total price of the furnace. You are not paying for a commodity but for front-loaded engineering expertise. View this as a critical investment to prevent much larger expenses and design flaws later.

Dependency and Vendor Lock-in

A highly integrated support system, particularly one reliant on proprietary remote diagnostic software, inevitably creates a degree of dependency on the original manufacturer. This is a trade-off: you gain unparalleled expert support, but it may limit your options for third-party service in the future.

Data and Security Implications

Allowing a vendor remote access for diagnostics means sharing operational data. It is crucial to have a clear Service Level Agreement (SLA) that defines data ownership, cybersecurity protocols, and how your intellectual property will be protected.

How to Evaluate Support When Choosing a Vendor

When comparing custom furnace manufacturers, use your primary goal to scrutinize their support offerings.

- If your primary focus is process innovation: Prioritize vendors who demonstrate deep engineering expertise and a truly collaborative spirit during the initial design phase.

- If your primary focus is operational stability and minimizing downtime: Scrutinize the 24/7 remote diagnostics capabilities and demand clear, contractually-obligated response times in the SLA.

- If your primary focus is workforce readiness: Evaluate the depth, quality, and location of the training programs offered for both your operators and maintenance teams.

Ultimately, the best support package transforms a furnace vendor from a simple supplier into a long-term partner invested in your production success.

Summary Table:

| Support Stage | Key Services | Benefits |

|---|---|---|

| Pre-Build | Collaborative design, Chamber optimization, Automation integration | Tailored solutions, Prevents costly modifications |

| Implementation | Global installation, Certified technician training | Ensures correct setup, Empowers team for proactive operation |

| Production | 24/7 remote diagnostics, Real-time troubleshooting | Minimizes downtime, Enables proactive maintenance |

Ready to elevate your lab's performance with a custom vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, backed by comprehensive support from design to daily operation. Contact us today to discuss how we can partner for your success!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab