At its core, the heat shield in a magnesium vacuum distillation furnace is a critical thermal barrier. Its purpose is to physically and thermally separate the high-temperature heating zone from the low-temperature condensation zone. This separation is the single most important factor in maintaining the steep temperature gradient required for the distillation process to function efficiently.

The entire success of vacuum distillation hinges on creating two distinct thermal environments: one hot enough to vaporize magnesium and one cold enough to condense it. The heat shield is the component engineered to enforce this critical separation, directly impacting both product yield and energy consumption.

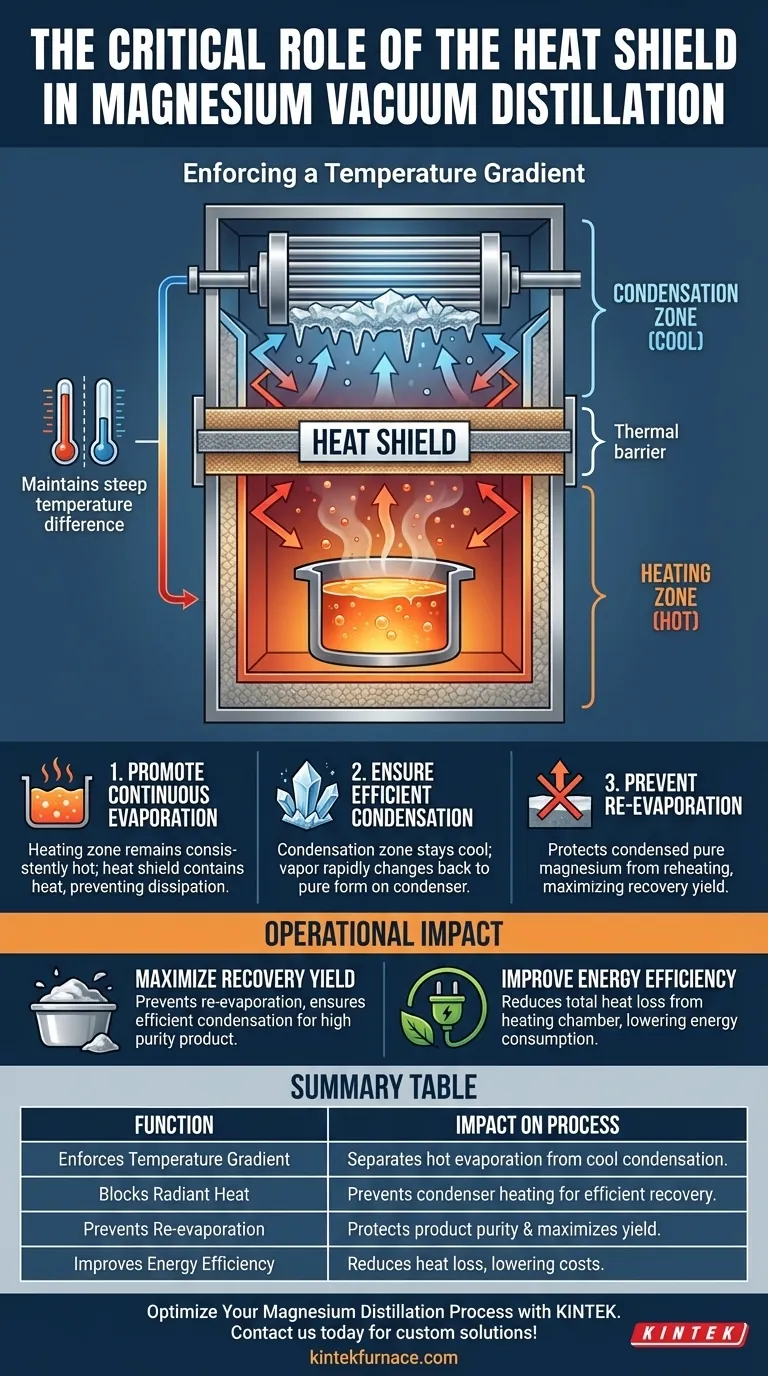

The Core Function: Enforcing a Temperature Gradient

The primary role of the heat shield is not just to insulate but to actively manage the flow of thermal energy within the furnace. It creates a sharp dividing line between two opposing processes.

Separating the Heating and Condensation Zones

A vacuum distillation furnace works by boiling magnesium in a lower chamber (the heating zone) and collecting the purified vapor in an upper chamber (the condensation zone).

The heat shield is positioned directly between these two areas, acting as a partition.

Blocking Radiant Heat Transfer

Its main job is to block direct heat radiation from the hot distillation area below from reaching the cool condenser above.

Without this shield, the condenser would heat up, disrupting its ability to cool the magnesium vapor back into a pure liquid or solid.

Why This Gradient is Critical for Magnesium Distillation

Maintaining this temperature difference is not a minor optimization; it is fundamental to the physics of the process. A stable, steep gradient ensures each stage of distillation can proceed without interference.

Promoting Continuous Evaporation

The heating zone must remain consistently hot to ensure a steady rate of magnesium evaporation. The heat shield helps contain this heat, preventing it from dissipating upwards and reducing energy loss.

Ensuring Efficient Condensation

Simultaneously, the condensation zone must remain cool. This allows the gaseous magnesium to rapidly change phase back into its pure form on the condenser's surface.

If the condenser becomes too warm, the magnesium vapor will not condense effectively, dramatically lowering the process efficiency.

Preventing Re-Evaporation

Perhaps most importantly, the shield prevents the already-condensed pure magnesium from being reheated by the lower chamber.

This protects the final product from turning back into a gas, which would reduce the overall recovery yield.

Understanding the Operational Impact

The effectiveness of the heat shield has a direct and measurable effect on the furnace's output and efficiency. A well-designed shield is a hallmark of an optimized system.

Maximizing Recovery Yield

By preventing re-evaporation and ensuring efficient condensation, the heat shield ensures that the maximum amount of vaporized magnesium is successfully recovered as pure product.

Improving Energy Efficiency

The shield functions as a powerful insulator. It reduces the total amount of heat lost from the heating chamber, meaning less energy is required to maintain the target distillation temperature.

A Secondary Structural Role

In many furnace designs, the heat shield also serves as a structural foundation. It can be used as a stable platform for mounting and securing the heater elements within the chamber.

How to Apply This to Your Goal

Your operational priority will determine how you view the function of the heat shield.

- If your primary focus is maximizing product yield: The shield's most critical function is preventing the re-evaporation of condensed magnesium.

- If your primary focus is reducing operational costs: The shield's role as a thermal insulator that minimizes heat loss is key to improving energy efficiency.

- If your primary focus is process stability and control: View the shield as the component that guarantees a consistent and reliable temperature gradient between the two critical zones.

Ultimately, the heat shield makes the entire vacuum distillation process viable by allowing two opposing thermal conditions to exist in close proximity.

Summary Table:

| Function | Impact on Process |

|---|---|

| Enforces Temperature Gradient | Separates hot evaporation zone from cool condensation zone. |

| Blocks Radiant Heat | Prevents condenser heating for efficient magnesium recovery. |

| Prevents Re-evaporation | Protects condensed product purity and maximizes final yield. |

| Improves Energy Efficiency | Reduces heat loss, lowering operational costs. |

Optimize Your Magnesium Distillation Process with KINTEK

A well-designed heat shield is critical for maximizing yield, purity, and energy efficiency in your vacuum distillation operations. The right furnace design makes all the difference.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Our team can help you design a vacuum furnace with a thermal management system tailored to your specific process goals.

Contact us today to discuss how our solutions can enhance your efficiency and product quality.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency