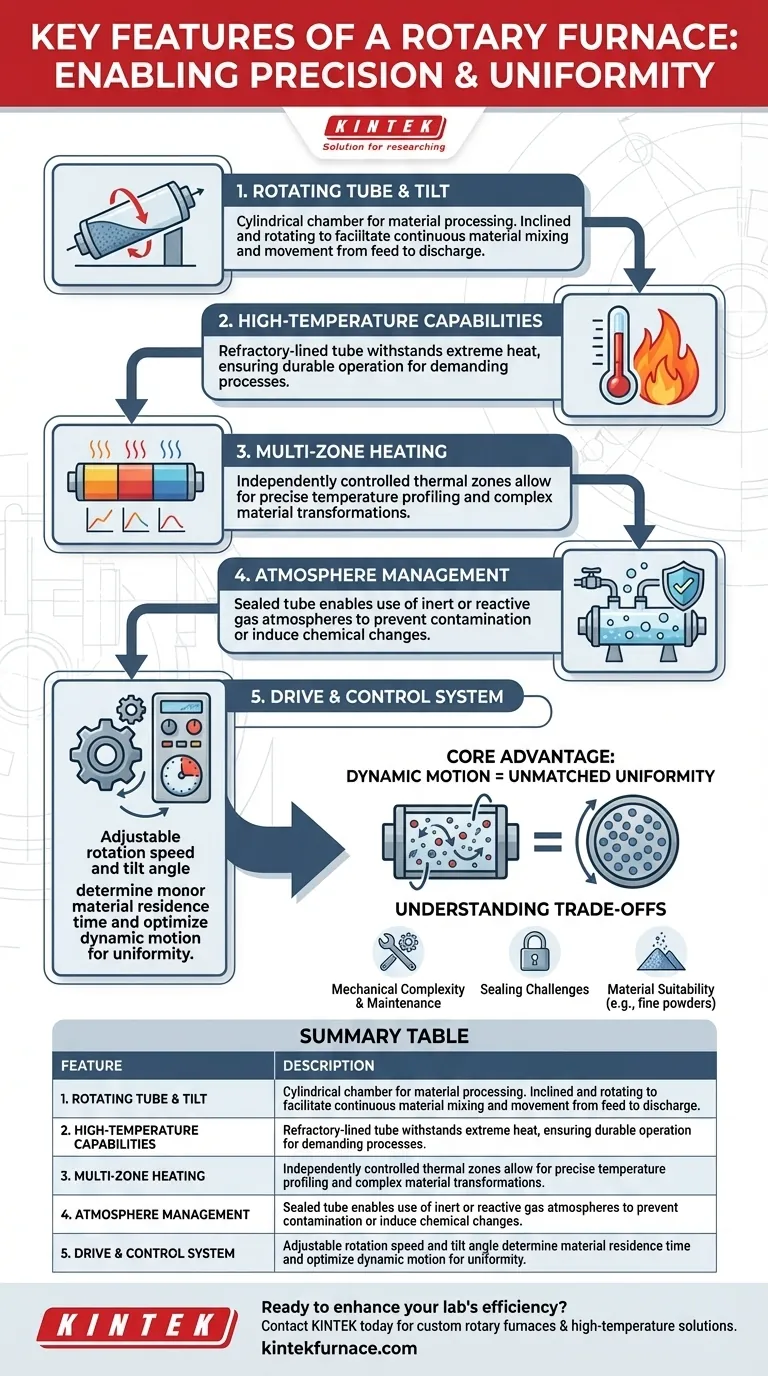

At its core, a rotary furnace is defined by five key features. These include a rotating cylindrical tube for material processing, high-temperature capabilities, precise multi-zone heating for controlled temperature profiles, versatile atmosphere management within the sealed tube, and a drive system that controls the rotation speed and tilt angle.

The central purpose of a rotary furnace is not just to heat material, but to do so with exceptional uniformity. Its defining feature—the rotation—creates a dynamic processing environment that continuously mixes the material, ensuring every particle is exposed to identical thermal and atmospheric conditions.

The Anatomy of a Rotary Furnace

To understand its features, you must first understand its fundamental components. These parts work in concert to create a controlled, continuous processing system.

The Rotating Tube

The heart of the furnace is the cylindrical chamber or tube that contains the process material. It is typically constructed from metal and lined with refractory materials to withstand extreme temperatures.

This tube is almost always mounted at a slight angle. This incline, combined with the rotation, facilitates the steady movement of material from the feed end to the discharge end.

The Heating System

Rotary furnaces use an indirect-fired design. The heating elements (either electric or gas burners) are located outside the process tube.

This separation is critical. It allows for precise temperature control and prevents combustion byproducts from contaminating the process atmosphere inside the tube, ensuring product purity.

The Drive and Control Mechanism

A motor-driven mechanism provides the rotational force. The speed of this rotation is a key process variable that can be precisely controlled.

Alongside rotation speed, many systems also allow for adjustment of the tube's tilt angle. Together, these two controls determine the residence time—how long the material spends inside the furnace.

Material Handling Systems

For continuous operation, rotary furnaces are equipped with automated feed and discharge systems. These systems introduce raw material at the higher, inlet end and collect the processed material as it exits the lower, outlet end, enabling high-throughput production.

How Key Features Drive Process Control

The physical components of the furnace enable a set of powerful features that give engineers precise control over the manufacturing process.

Dynamic Motion for Unmatched Uniformity

The constant tumbling motion imparted by the rotation is the furnace's most significant advantage. It ensures every particle is repeatedly exposed to the heat source and the internal atmosphere.

This eliminates hot spots and gradients common in static furnaces, resulting in a highly consistent and homogenous final product.

Precision Temperature Profiling with Multi-Zone Heating

The furnace's length is divided into multiple, independently controlled thermal zones. This allows you to create a specific temperature "recipe" or profile along the tube.

A typical profile might involve a pre-heating zone, a high-temperature reaction zone, and a controlled cooling zone, all within a single continuous process. This level of thermal management is essential for complex material transformations like calcination or sintering.

Versatile Atmosphere Management

The sealed nature of the process tube allows for complete control over the internal atmosphere. Specialized seals at the inlet and outlet prevent ambient air from entering.

This feature is critical for processes that require inert atmospheres (using gases like nitrogen or argon) to prevent oxidation, or reactive atmospheres to induce specific chemical changes in the material.

Understanding the Trade-offs and Considerations

While powerful, rotary furnaces are not a universal solution. Their unique design comes with specific operational considerations.

Mechanical Complexity and Maintenance

The rotating components, particularly the seals and the drive mechanism, introduce mechanical complexity not found in static batch furnaces. These parts require regular inspection and maintenance to ensure reliability and prevent downtime.

Sealing Challenges

Maintaining a perfectly hermetic seal on a rotating tube, especially at high temperatures and pressures, is a significant engineering challenge. While modern seals are highly effective, they can be a potential point of failure for processes requiring extreme atmospheric purity.

Material Suitability

The tumbling action is not suitable for all materials. Extremely fine powders can be carried out of the furnace by the process gas flow (a phenomenon called elutriation), while sticky or agglomerating materials may build up on the tube walls, hindering flow and heat transfer.

Making the Right Choice for Your Process

Selecting the right thermal processing equipment depends entirely on your end goal. A rotary furnace is a specialized tool designed for specific outcomes.

- If your primary focus is achieving the highest possible material uniformity: The continuous mixing action of a rotary furnace is superior to almost any batch processing method.

- If your primary focus is continuous, high-throughput production: The integrated feed and discharge systems make rotary furnaces ideal for integration into automated industrial lines.

- If your primary focus is processing under a controlled atmosphere: The sealed tube design is a major advantage, but you must factor in the maintenance of the rotary seals.

- If your primary focus is simplicity and process flexibility for small, varied batches: A static box or muffle furnace may be a more practical and lower-maintenance choice, though you will sacrifice uniformity and throughput.

Ultimately, understanding these core features empowers you to determine if the dynamic, continuous processing of a rotary furnace aligns with your specific material and production goals.

Summary Table:

| Feature | Description |

|---|---|

| Rotating Tube | Cylindrical chamber that rotates and tilts for continuous material mixing and movement. |

| High-Temperature Capability | Withstands extreme heat with refractory-lined tubes for durable operation. |

| Multi-Zone Heating | Independently controlled thermal zones for precise temperature profiling. |

| Atmosphere Management | Sealed tube allows inert or reactive gas control to prevent contamination. |

| Drive System | Adjustable rotation speed and tilt angle to control material residence time. |

Ready to enhance your lab's efficiency with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced rotary furnaces and other systems like Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior uniformity and process control. Contact us today to discuss how we can support your specific goals!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput