A vertical vacuum furnace serves as the critical separation vessel in the purification of Rubidium Chloride by creating a strictly controlled high-temperature, low-pressure environment. Its primary function is to induce the physical separation of impurities through selective volatilization and thermal decomposition, effectively removing contaminants while preserving the target compound.

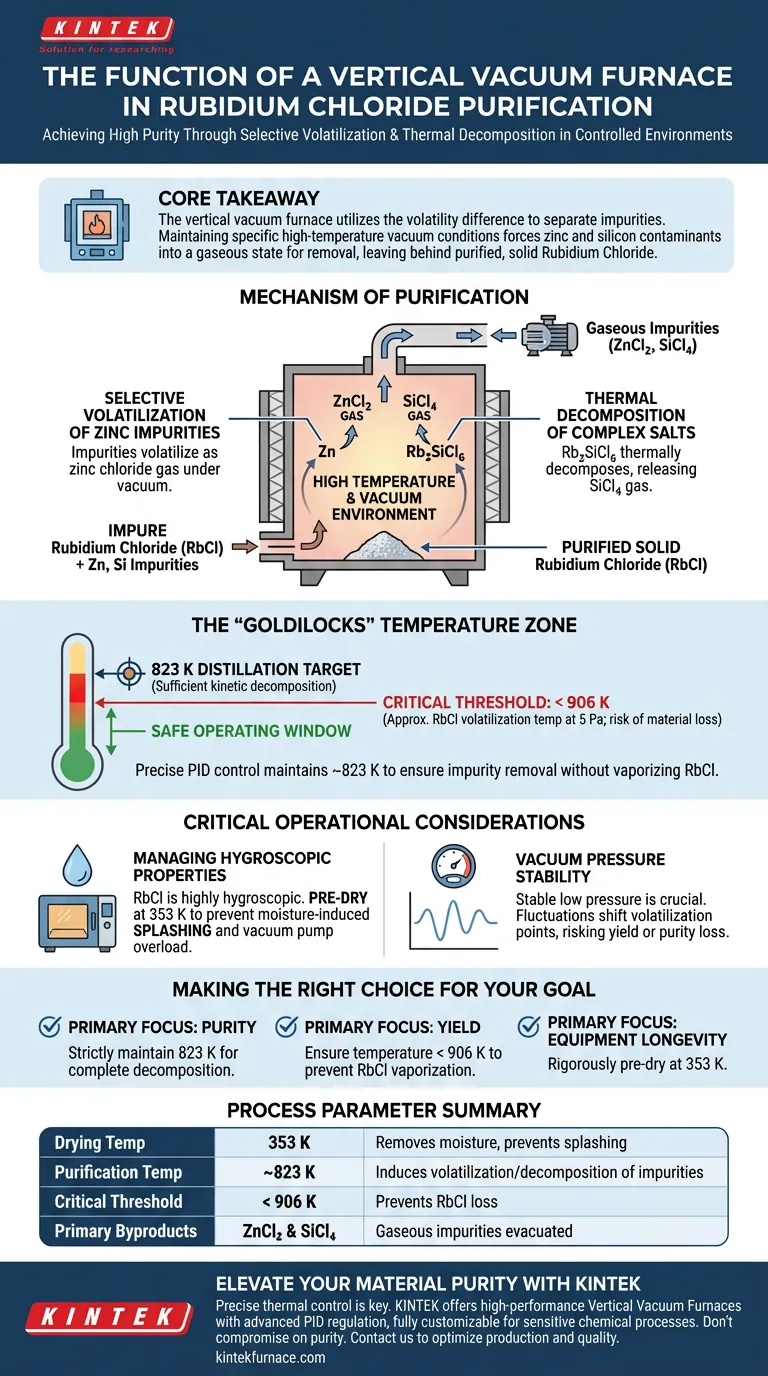

Core Takeaway The vertical vacuum furnace utilizes the difference in volatility between Rubidium Chloride and its impurities. By maintaining a vacuum at specific temperatures, it forces zinc and silicon contaminants into a gaseous state for removal, leaving behind purified, solid Rubidium Chloride.

The Mechanism of Purification

Selective Volatilization of Impurities

The furnace operates on the principle that different compounds transition to gas at different temperatures.

The primary goal is the removal of zinc impurities. Under the furnace's vacuum conditions, these impurities volatilize as zinc chloride gas, separating them from the solid Rubidium Chloride batch.

Thermal Decomposition of Complex Salts

Beyond simple volatilization, the furnace facilitates chemical decomposition.

Rubidium Chloride often contains complex double salts, specifically Rb2SiCl6. The high-temperature environment causes these salts to thermally decompose, releasing gaseous silicon tetrachloride (SiCl4).

Once in a gaseous state, both the zinc and silicon byproducts are evacuated from the chamber by the vacuum system, isolating the purified Rubidium Chloride.

The "Goldilocks" Temperature Zone

The effectiveness of the furnace relies entirely on precise temperature regulation, typically managed by PID control systems.

The process targets a distillation temperature of approximately 823 K.

This temperature is sufficient to drive the kinetic decomposition of impurities but remains safely below 906 K, which is the approximate volatilization temperature of Rubidium Chloride at 5 Pa.

By staying in this window, the system achieves high impurity removal rates without vaporizing the Rubidium Chloride, preventing raw material loss.

Critical Operational Considerations

Managing Hygroscopic Properties

Rubidium Chloride is highly hygroscopic, meaning it readily absorbs moisture from the air.

Before high-temperature processing, the material must be thoroughly dried (often at 353 K). Failure to remove absorbed water or residual liquids like silicon tetrachloride can lead to splashing inside the furnace.

Sudden water vaporization in a vacuum causes rapid expansion, which can physically displace the raw material and place an excessive load on the vacuum pump system.

Vacuum Pressure Stability

The relationship between temperature and pressure is non-linear.

The furnace must maintain a stable low-pressure environment (vacuum). If the pressure fluctuates significantly, the volatilization point of the Rubidium Chloride shifts, potentially risking yield loss or incomplete purification.

Making the Right Choice for Your Goal

To maximize the efficiency of a vertical vacuum furnace in this application, focus on the balance between thermal energy and vacuum pressure.

- If your primary focus is Purity: Maintain the temperature strictly at 823 K to ensure complete decomposition of Rb2SiCl6 without contaminating the final product with unrefined vapors.

- If your primary focus is Yield: Ensure the temperature never exceeds the 906 K threshold to prevent the Rubidium Chloride itself from vaporizing and exiting the system.

- If your primary focus is Equipment Longevity: rigorously pre-dry materials at 353 K to prevent moisture-induced splashing and vacuum pump overload.

Success in this process is defined by the rigorous control of thermal thresholds to separate phases without losing the product.

Summary Table:

| Process Parameter | Target Value/Setting | Function in Purification |

|---|---|---|

| Drying Temp | 353 K | Removes moisture to prevent splashing and pump overload |

| Purification Temp | ~823 K | Induces volatilization of Zn and decomposition of Rb2SiCl6 |

| Critical Threshold | < 906 K | Prevents loss of Rubidium Chloride through vaporization |

| Primary Byproducts | ZnCl2 & SiCl4 | Gaseous impurities removed via continuous vacuum system |

Elevate Your Material Purity with KINTEK

Precise thermal control is the difference between high-yield purification and material loss. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Vertical Vacuum Furnaces, Muffle, Tube, and CVD systems tailored for sensitive chemical processes like Rubidium Chloride purification.

Our systems feature advanced PID regulation and stable vacuum environments, all fully customizable to meet your lab's unique technical requirements. Don't compromise on purity. Contact our technical specialists today to discover how KINTEK’s high-temperature solutions can optimize your production efficiency and material quality.

Visual Guide

References

- Cui Xi, Tao Qu. A Study on the Removal of Impurity Elements Silicon and Zinc from Rubidium Chloride by Vacuum Distillation. DOI: 10.3390/ma17091960

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does a horizontal vacuum furnace handle different part sizes? Optimize Loading for Uniform Heating

- What is the purpose of using a vacuum drying oven? Ensure Accurate Powder Characterization and Material Integrity

- Why must humidity be controlled in aluminum alloy furnaces? Prevent Blistering & Hydrogen Damage Now

- Why are ZrO₂ ceramic blocks utilized as auxiliary fixtures during the vacuum brazing of TC4 titanium alloys?

- Why is an industrial-grade high-temperature sintering furnace required for the production of multi-channel ceramic membrane supports? Key Roles in Material Transformation

- Why is it necessary to treat porous carbon samples in a vacuum drying oven at 90 °C before electrode coating?

- What is the purpose of a high vacuum welding furnace in cemented carbide and tool manufacturing? Ensure Strong, Contamination-Free Bonds

- How does temperature control precision of industrial melting furnaces affect intermetallic phase selection?