Strict humidity control is non-negotiable in aluminum solution heat treatment because water vapor chemically attacks the metal at high temperatures. This reaction introduces atomic hydrogen into the alloy, which accumulates internally and causes the metal to physically deform, creating permanent defects known as blisters.

The presence of moisture triggers a chain reaction that injects hydrogen into the alloy structure, causing internal pressure buildup at oxide sites and resulting in irreversible surface blistering and hydrogen embrittlement.

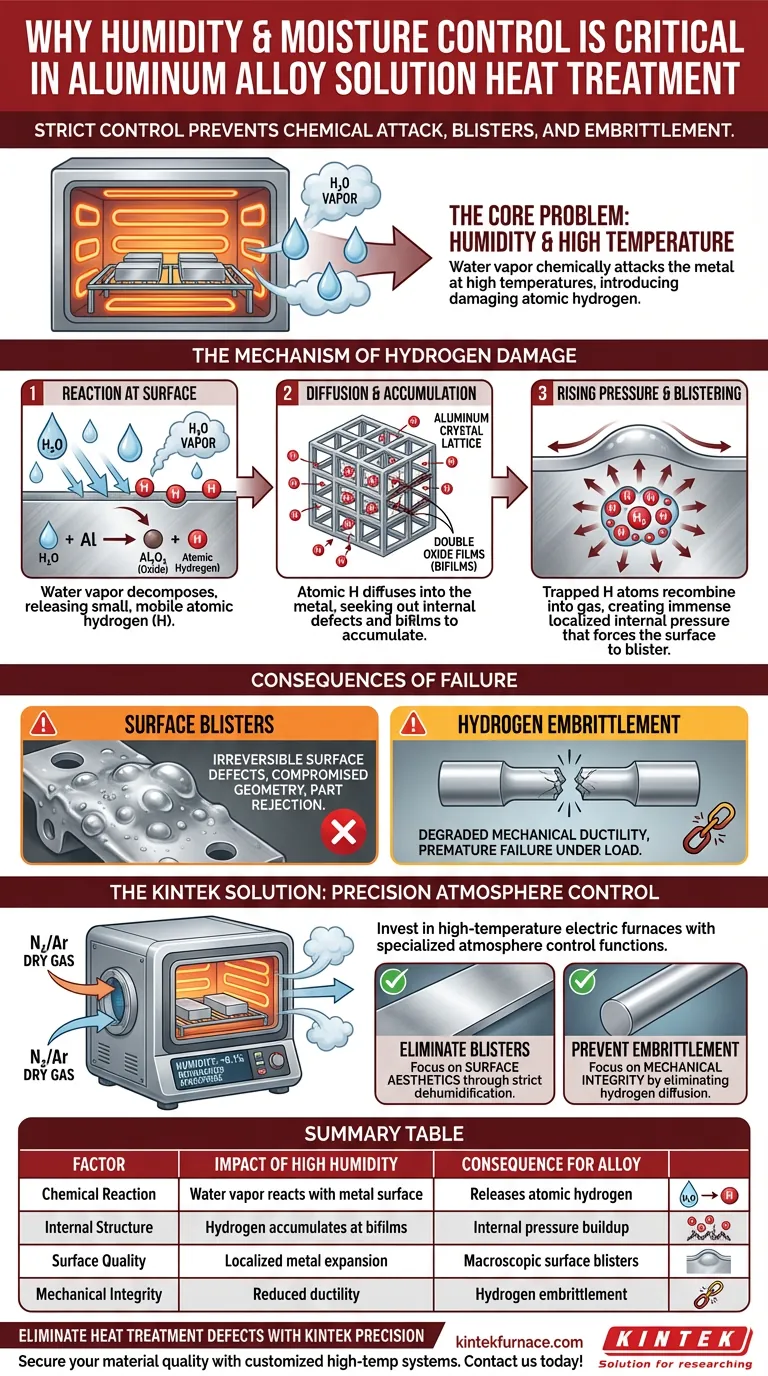

The Mechanism of Hydrogen Damage

The Reaction at the Surface

When aluminum alloys are exposed to high temperatures in a moist environment, water vapor reacts directly with the metal surface.

This chemical reaction decomposes the water molecules, releasing atomic hydrogen as a byproduct.

Diffusion into the Metal Lattice

Unlike gas molecules, atomic hydrogen is small enough to diffuse rapidly into the solid aluminum matrix.

Once inside, these atoms migrate through the lattice, seeking out internal imperfections.

Accumulation at Bifilms

The diffusing hydrogen atoms tend to gather at specific internal defects known as double oxide films (bifilms).

These microscopic films act as traps, collecting the hydrogen that has penetrated the surface.

From Internal Pressure to Surface Failure

Rising Internal Pressure

As hydrogen continues to accumulate at these bifilm sites, the concentration increases significantly.

The trapped atoms recombine into gas, causing a massive spike in localized internal pressure within the metal.

Formation of Macroscopic Blisters

The internal pressure eventually exceeds the strength of the material, forcing the metal near the surface to expand outward.

This manifests as macroscopic surface hydrogen blisters, a defect that compromises both the geometry and the structural integrity of the part.

Understanding the Trade-offs

Equipment Capability vs. Risk

To prevent this phenomenon, operators must utilize high-temperature electric furnaces equipped with precision atmosphere control functions.

While these systems may represent a higher initial capital investment, relying on standard furnaces without moisture regulation creates a high risk of part rejection.

The Cost of Embrittlement

Beyond visible blisters, the presence of hydrogen leads to hydrogen embrittlement.

Failing to control humidity does not just ruin the surface finish; it degrades the mechanical ductility of the alloy, potentially causing premature failure under load.

Making the Right Choice for Your Process

To ensure the viability of your aluminum components, you must align your equipment capabilities with your quality goals.

- If your primary focus is Surface Aesthetics: Ensure your furnace atmosphere is strictly dehumidified to prevent the chemical reactions that cause visible blistering.

- If your primary focus is Mechanical Integrity: Prioritize precision atmosphere control to eliminate hydrogen diffusion, thereby preventing internal embrittlement.

Control the atmosphere to control the material properties.

Summary Table:

| Factor | Impact of High Humidity | Consequence for Alloy |

|---|---|---|

| Chemical Reaction | Water vapor reacts with metal surface | Releases atomic hydrogen |

| Internal Structure | Hydrogen accumulates at bifilms | Internal pressure buildup |

| Surface Quality | Localized metal expansion | Macroscopic surface blisters |

| Mechanical Integrity | Reduced ductility | Hydrogen embrittlement |

Eliminate Heat Treatment Defects with KINTEK Precision

Don't let humidity compromise your aluminum components. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, and Vacuum systems designed for rigorous atmosphere control. Whether you require standard or fully customizable high-temp furnaces, our solutions ensure the chemical stability and mechanical integrity your projects demand.

Ready to upgrade your thermal processing? Contact us today to secure your material quality!

Visual Guide

References

- Time-Dependent Failure Mechanisms of Metals; The Role of Precipitation Cleavage. DOI: 10.20944/preprints202508.2134.v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What role does a vacuum annealing furnace play in Bi4I4 single crystals? Master Precise Fermi Level Engineering

- What are the benefits of using a vacuum environment in heat treatment? Achieve Superior Metallurgical Control

- What components are used in the construction of vacuum graphitizing furnaces? A Guide to High-Temp Performance

- What are the characteristics, advantages, and disadvantages of a vacuum sintering furnace? Maximize Material Purity and Performance

- What are the main advantages of vacuum heat treatment? Achieve Superior Metallurgical Outcomes and Cost Efficiency

- How does a glow discharge ion diffusion furnace facilitate the low-temperature plasma carburizing of AISI 316L?

- What is the primary application of vacuum heat treating furnaces in aerospace? Enhance Component Performance with Precision

- What is the significance of purification and degassing in high-temperature vacuum furnaces? Achieve Superior Material Purity and Performance