At its core, the significance of purification and degassing in a high-temperature vacuum furnace is to create materials with a level of purity and structural integrity that is impossible to achieve in an open atmosphere. By removing the reactive gases of air and actively pulling unwanted elements out of the material itself, the furnace enables the production of components with superior performance, strength, and reliability.

A vacuum furnace acts as both a shield and a extractor. It shields the material from atmospheric contamination like oxygen and actively extracts trapped gases and volatile impurities, leading to a fundamentally cleaner and more robust final product.

The Core Mechanisms: How Vacuum Enables Purity

Understanding how a vacuum furnace purifies a material requires looking at two distinct actions: preventing new contaminants from entering and removing existing ones from within.

Preventing Atmospheric Contamination

At high temperatures, most materials are highly reactive. When heated in air, metals instantly form oxides on their surface, introducing impurities and altering their properties.

A vacuum furnace works by first pumping out the air and its reactive components, primarily oxygen and nitrogen. By creating an environment below atmospheric pressure, it starves the high-temperature reaction of the fuel it needs, effectively preventing oxidation and contamination.

Actively Removing Volatile Impurities

Many raw materials contain trace elements that are undesirable in the final product. The vacuum environment facilitates their removal through a process similar to boiling.

Under high vacuum, the boiling point of all elements is significantly lowered. By carefully controlling the temperature, you can cause volatile impurities—those with a lower boiling point than the base material—to turn into a gas. This vapor is then simply pumped out of the chamber, leaving behind a purer base material.

Degassing: Releasing Trapped Gases

Materials, especially metals during casting, can dissolve and trap gases like hydrogen and oxygen within their atomic structure. These trapped gases create microscopic voids and internal stress points.

The high vacuum outside the material creates a strong pressure differential. This forces the dissolved gas atoms to migrate out of the material's internal structure and into the furnace chamber, where they are removed by the vacuum system. This process, known as degassing, is critical for improving a material's structural integrity.

The Tangible Results: Why Purity Matters

The theoretical benefits of purification and degassing translate directly into measurable improvements in product quality and performance across various industries.

Achieving High-Purity Metals

For industries like aerospace and medical devices, material purity is paramount. Processes for creating high-purity titanium and niobium rely on vacuum furnaces to remove contaminants that would otherwise compromise their strength and corrosion resistance.

Enhancing Mechanical Properties

The removal of trapped gases and impurities has a profound impact. It reduces internal porosity and prevents issues like hydrogen embrittlement, resulting in materials that are denser, stronger, and more ductile. This is essential for high-stress components that cannot afford to fail.

Ensuring Performance in Electronics

In the manufacturing of electronic components such as vacuum tubes or specialized sensors, even microscopic amounts of trapped gas can be released over time, poisoning the internal vacuum and causing the device to fail. Degassing parts in a vacuum furnace beforehand ensures long-term stability and reliability.

Understanding the Trade-offs and Considerations

While powerful, the vacuum purification process is not a universal solution and requires careful control.

Control is Not Automatic

Effective purification and degassing depend on a precise balance of temperature and vacuum level. The wrong parameters can be ineffective, fail to remove the target impurities, or even damage the base material by causing it to vaporize.

Not All Impurities are Volatile

This method is most effective for removing volatile impurities and dissolved gases. Contaminants with a boiling point higher than the base material will not be removed by this process and require different purification methods.

Cost and Complexity

Vacuum furnaces are inherently more complex and expensive to acquire, operate, and maintain than standard atmospheric furnaces. Their use is typically justified only when the demand for extreme purity and performance outweighs the additional operational cost.

Making the Right Choice for Your Process

Applying these principles effectively depends entirely on your end goal.

- If your primary focus is material strength and reliability: Prioritize degassing to eliminate internal voids and prevent hydrogen embrittlement, leading to a stronger, more ductile final product.

- If your primary focus is chemical purity for alloys or electronics: Concentrate on the removal of volatile contaminants and the absolute prevention of oxidation to ensure predictable chemical and electrical properties.

- If your primary focus is eliminating surface defects: Use the vacuum environment primarily as a shield to prevent the formation of oxides and other surface contaminants during high-temperature processing.

Mastering the vacuum environment is fundamental to unlocking the full potential of advanced materials.

Summary Table:

| Aspect | Key Points |

|---|---|

| Prevents Contamination | Removes oxygen and nitrogen to avoid oxidation and surface impurities. |

| Removes Volatile Impurities | Lowers boiling points to extract gases, improving chemical purity. |

| Degassing | Releases trapped gases like hydrogen to reduce voids and increase strength. |

| Benefits | Higher purity metals, enhanced mechanical properties, reliable electronics. |

| Considerations | Requires precise temperature and vacuum control; not for non-volatile impurities. |

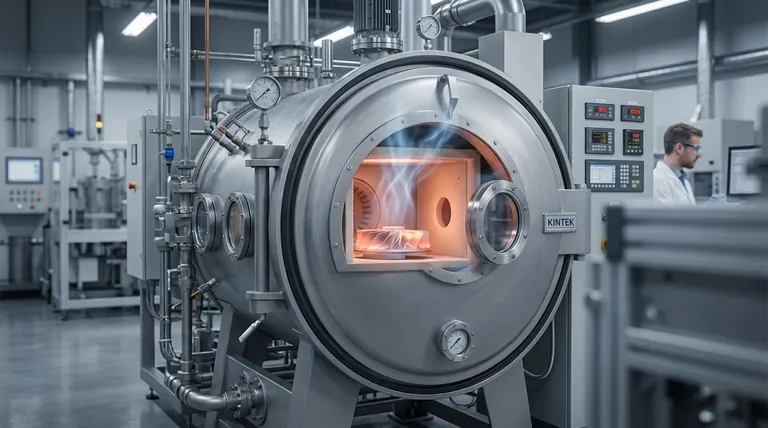

Unlock the full potential of your materials with KINTEK's advanced high-temperature vacuum furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures precise handling of purification and degassing for superior purity, strength, and reliability in industries like aerospace and electronics. Contact us today to discuss how our expertise can elevate your process and deliver measurable results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision