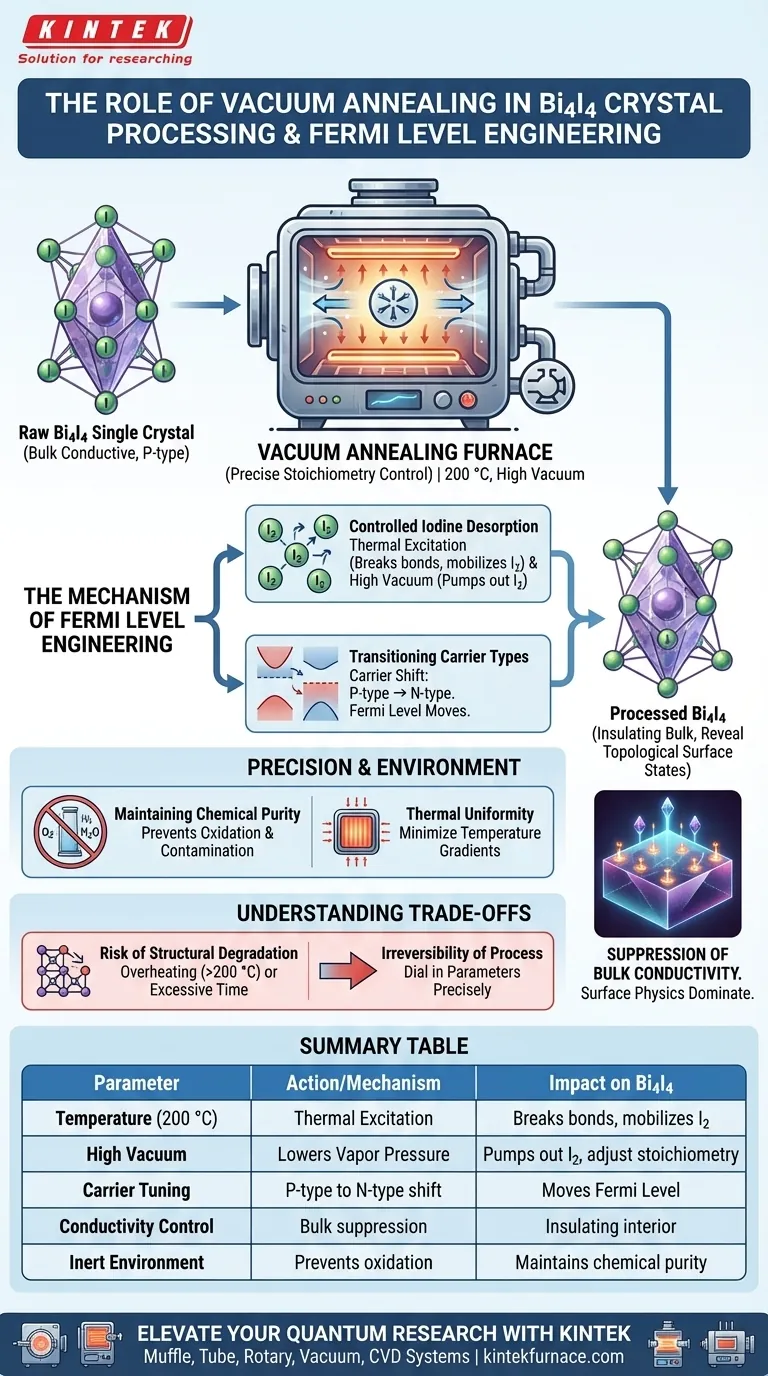

The vacuum annealing furnace functions as a critical instrument for precise stoichiometry control in the post-processing of Bi4I4 single crystals. By subjecting the material to prolonged heating at 200 °C under high vacuum, the furnace creates the exact thermal environment needed to modify the crystal's electronic structure and facilitate Fermi level engineering.

Core Takeaway Ideally, Bi4I4 acts as a topological insulator, but native defects often render the bulk material too conductive to study effectively. The vacuum annealing process solves this by utilizing thermal excitation to remove excess iodine, effectively "turning off" bulk conduction to reveal the exotic physics occurring on the surface.

The Mechanism of Fermi Level Engineering

Controlled Iodine Desorption

The primary function of the furnace is to provide the thermal excitation necessary to break specific chemical bonds within the crystal lattice.

When held at 200 °C, the energy provided is sufficient to mobilize excess iodine atoms that are loosely bound within the structure. The high-vacuum environment is equally critical, as it lowers the vapor pressure required for these iodine atoms to leave the crystal surface, effectively "pumping" them out of the material.

Transitioning Carrier Types

This desorption process directly alters the charge carrier balance within the Bi4I4 crystal.

Initially, the material may exhibit p-type behavior (dominated by "holes") due to the excess iodine. As the annealing process removes this iodine, the carrier type transitions from holes to electrons. This shift is the essence of Fermi level engineering—physically moving the Fermi level across the band gap to a desired position.

Suppression of Bulk Conductivity

For researchers to observe topological surface states, the interior (bulk) of the crystal must be electrically insulating.

Unprocessed crystals often have high bulk conductivity, which "shorts out" and obscures surface signals. The vacuum annealing process significantly reduces bulk conductivity to extremely low levels, rendering the bulk insulating and allowing the unique surface properties to dominate electronic transport measurements.

The Role of Precision and Environment

Maintaining Chemical Purity

While standard annealing can occur in inert gases, a vacuum environment is superior for Bi4I4 post-processing.

As noted in chemical vapor transport methods, high-vacuum conditions (often around 1 x 10^-8 bar) prevent the crystal from reacting with atmospheric oxygen or moisture. This ensures that the changes in the crystal are strictly due to iodine stoichiometry adjustments, rather than oxidation or contamination.

Thermal Uniformity

Vacuum annealing furnaces are designed to minimize temperature gradients, ensuring the entire crystal is treated evenly.

Advanced temperature control systems prevent overheating, which could decompose the crystal structure entirely, or undercooling, which would fail to trigger the necessary desorption. This uniformity ensures that the electronic properties are consistent throughout the entire sample, rather than varying from one end to the other.

Understanding the Trade-offs

The Risk of Structural Degradation

While removing iodine is necessary for electronic tuning, it comes with a structural cost.

If the temperature exceeds 200 °C or the annealing time is excessive, the crystal may lose too much iodine. This can lead to the collapse of the crystal lattice or the formation of unwanted secondary phases, effectively destroying the sample's single-crystal quality.

Irreversibility of the Process

Fermi level engineering via desorption is largely a one-way process in this context.

Once the iodine is desorbed and the Fermi level has shifted, re-introducing iodine into the lattice to reverse the effect is chemically difficult and impractical without re-growing the crystal. Therefore, the parameters of the vacuum annealing furnace must be dialed in with absolute precision to avoid "overshooting" the target electronic state.

Making the Right Choice for Your Goal

The vacuum annealing furnace is the bridge between a raw grown crystal and a usable device for quantum research.

- If your primary focus is Observing Topological States: Prioritize long-duration annealing to maximize bulk resistivity, ensuring the interior of the crystal does not interfere with surface measurements.

- If your primary focus is Crystal Structural Integrity: Monitor the temperature strictly at 200 °C; exceeding this threshold risks degrading the lattice quality for the sake of electronic tuning.

Ultimately, the vacuum annealing furnace transforms Bi4I4 from a standard semiconductor into a platform for exploring quantum matter by precisely removing the chemical noise that obscures its true nature.

Summary Table:

| Process Parameter | Action/Mechanism | Impact on Bi4I4 Crystal |

|---|---|---|

| Temperature (200 °C) | Thermal excitation | Breaks bonds to mobilize excess iodine atoms. |

| High Vacuum | Lowers vapor pressure | Effectively "pumps" out iodine to adjust stoichiometry. |

| Carrier Tuning | P-type to N-type shift | Moves the Fermi level to the desired electronic state. |

| Conductivity Control | Bulk suppression | Renders the interior insulating to reveal surface states. |

| Inert Environment | Prevents oxidation | Maintains chemical purity by avoiding atmospheric reactions. |

Elevate Your Quantum Research with Precision Thermal Solutions

Achieving the perfect electronic state in Bi4I4 single crystals requires absolute control over temperature and vacuum levels. KINTEK provides the high-performance tools necessary for successful Fermi level engineering.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all customizable to meet your unique research specifications. Ensure thermal uniformity and eliminate bulk conductivity with our industry-leading technology.

Ready to optimize your material processing? Contact us today to find the perfect furnace for your laboratory!

Visual Guide

References

- Dong Chen, Claudia Felser. Observation of Surface 2D Electron Gas in Highly Bulk‐Insulating Bi<sub>4</sub>I<sub>4</sub>. DOI: 10.1002/andp.202500136

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the electronics and semiconductor applications of furnace brazing? Achieve Reliable, High-Performance Component Joining

- What role does high vacuum heating equipment play in copper-boron wetting? Achieve 10^-6 mbar Precision

- What are the benefits of vertical vacuum furnaces with gas pressure quenching? Achieve Superior Heat Treatment with Minimal Distortion

- What are the technical challenges of SEM in-situ furnaces? Optimize High-Temperature Dynamic Observation

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- What is the core role of a vacuum melting furnace in the process of recovering elemental magnesium from slag? | Achieve High-Purity Metal Recovery

- Why is Vacuum Consumable Arc Remelting (VAR) required for Ni-W-Co-Ta? Achieve Ultra-Pure Alloy Structural Integrity

- What is the disadvantage of graphite furnace? Key Trade-offs for Ultra-Trace Analysis