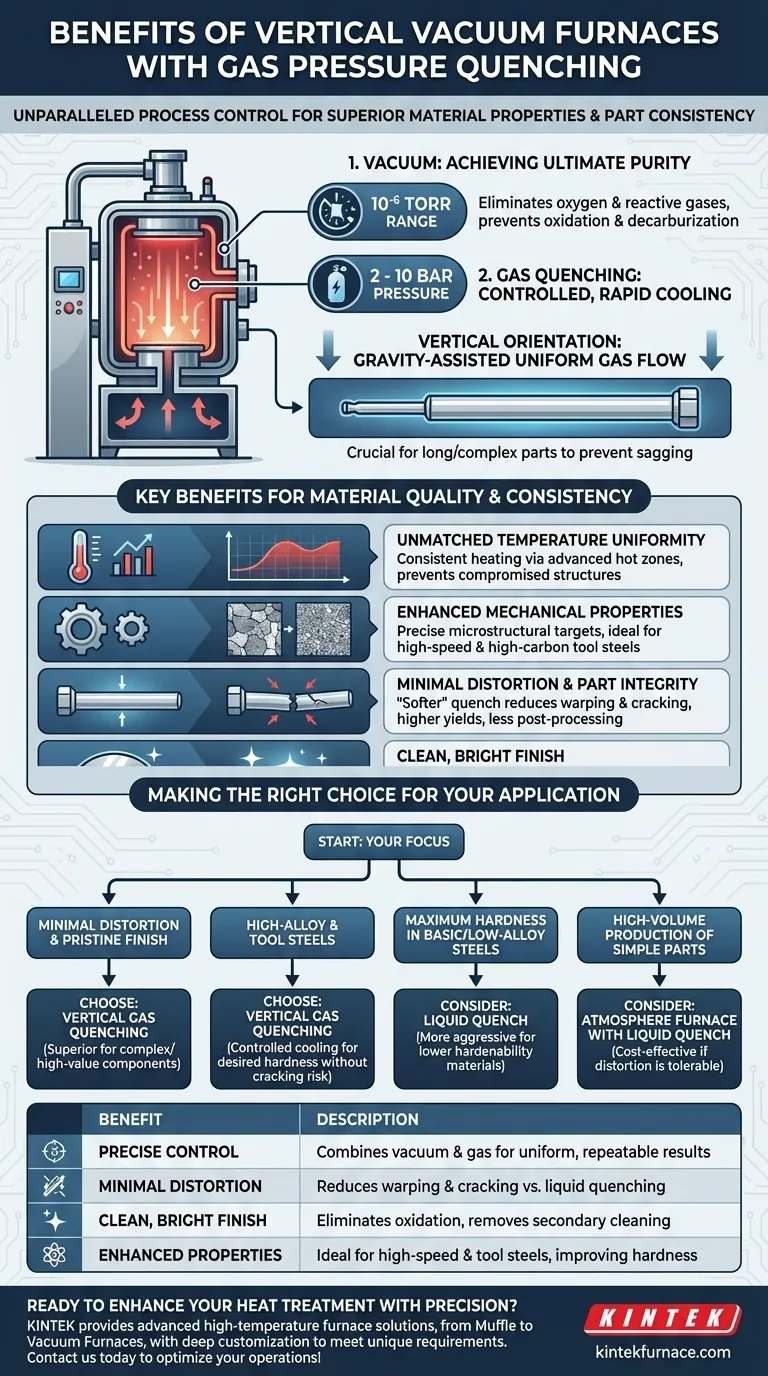

At their core, vertical vacuum furnaces with gas pressure quenching offer an unparalleled level of process control, resulting in superior material properties and exceptional part consistency. They achieve this by combining a highly controlled, contaminant-free vacuum environment with rapid, uniform gas quenching, enabling precise and repeatable heat treatment for a wide range of demanding applications.

The primary advantage of this technology is not just rapid cooling, but controlled cooling in an exceptionally clean environment. This minimizes part distortion and eliminates surface contamination, leading to finished parts that require less post-processing and meet the most stringent quality standards.

The Foundation: How Vacuum and Gas Quenching Work Together

To understand the benefits, you must first understand the two core components of the process: the vacuum and the quench.

Achieving Ultimate Purity with Vacuum

The process begins by placing parts inside a sealed chamber and removing the atmosphere to a high vacuum, often in the 10⁻⁶ torr range.

This near-perfect vacuum eliminates oxygen and other reactive gases. The immediate benefit is the prevention of oxidation and decarburization on the part's surface, even at extreme temperatures up to 1315°C (2400°F).

The Role of High-Pressure Gas Quenching

Once the part is heated to the target temperature, the heating elements turn off, and the chamber is rapidly backfilled with a high-purity inert gas, such as nitrogen or argon.

This gas is injected at high pressure, typically between 2 and 10 bar, creating a powerful and turbulent flow that rapidly and uniformly extracts heat from the part. The ability to select the pressure allows for precise control over the cooling rate.

Why Vertical Orientation Matters

The vertical design is a key engineering choice. It allows gravity to assist in creating a highly uniform gas flow from top to bottom, enveloping the component.

This is especially critical for long, cylindrical, or complex parts that could sag or distort under their own weight in a horizontal furnace. The result is more consistent cooling across the entire part surface.

Key Benefits for Material Quality and Consistency

The combination of vacuum, precise temperature control, and uniform gas quenching directly translates into tangible improvements in the final product.

Unmatched Temperature Uniformity

Modern vertical furnaces utilize advanced, often modular, all-graphite or all-metal hot zones and sophisticated PC-based controls. This ensures that the temperature is consistent across the entire working volume, preventing hot or cold spots that could compromise the part's metallurgical structure.

Enhanced Mechanical Properties

By eliminating surface reactions and precisely managing the cooling rate, gas quenching allows metallurgists to hit the exact microstructural targets required for a material. This is ideal for developing the full hardness and wear resistance of high-speed steels and high-carbon, high-chromium tool steels.

Minimal Distortion and Part Integrity

This is arguably the most significant advantage over traditional liquid quenching (oil or water). Gas is a "softer" quenching medium, reducing the severe thermal shock that causes parts to warp, bend, or crack. This translates to higher yields of usable parts and less need for costly post-heat-treat straightening or machining.

A Clean, Bright Finish

Because the entire process occurs in a contaminant-free environment, parts emerge from the furnace with a clean, bright finish. This often eliminates the need for secondary cleaning operations like shot blasting or chemical stripping, saving both time and money.

Understanding the Trade-offs and Considerations

While powerful, this technology is not a universal solution. An objective assessment requires understanding its limitations.

Cooling Rate Limitations

While fast, gas quenching cannot achieve the extreme cooling rates of an aggressive water or oil quench. This makes it perfectly suited for materials with high hardenability (air-hardening steels) but potentially too slow for some low-alloy steels that require a more severe quench to achieve maximum hardness.

Initial Investment and Complexity

These furnaces are sophisticated, automated systems that represent a significant capital investment compared to simpler atmosphere furnaces. They also require skilled technicians for operation and maintenance to ensure optimal performance and uptime.

Gas Consumption Costs

High-pressure quenching consumes a considerable amount of high-purity inert gas. This represents an ongoing operational cost that must be factored into the total cost per part.

Making the Right Choice for Your Application

Selecting the correct heat treatment process depends entirely on your material, part geometry, and final quality requirements.

- If your primary focus is minimal distortion and a pristine finish: Vertical gas quenching is the superior choice, especially for complex, high-value components.

- If your primary focus is processing high-alloy and tool steels: The controlled cooling rates of gas quenching are perfectly suited for achieving desired hardness without the cracking risk associated with liquid quenching.

- If your primary focus is maximum hardness in basic, low-alloy steels: A more aggressive liquid quench in a traditional furnace might be necessary if gas quenching proves unable to cool the material fast enough.

- If your primary focus is high-volume production of simple parts where some distortion is tolerable: A conventional atmosphere furnace with a liquid quench may offer a more cost-effective solution.

By understanding these core principles, you can confidently select the heat treatment process that delivers the precise material properties and part quality your application demands.

Summary Table:

| Benefit | Description |

|---|---|

| Precise Process Control | Combines vacuum and gas quenching for uniform cooling and repeatable results. |

| Minimal Distortion | Reduces warping and cracking compared to liquid quenching, lowering post-processing needs. |

| Clean, Bright Finish | Eliminates oxidation and contamination, often removing secondary cleaning steps. |

| Enhanced Mechanical Properties | Ideal for high-speed and tool steels, improving hardness and wear resistance. |

| Uniform Temperature | Advanced hot zones ensure consistent heating across parts for better quality. |

Ready to enhance your heat treatment processes with precision and reliability? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're working with high-value materials or need minimal distortion, our experts can tailor a solution for you. Contact us today to discuss how we can optimize your operations and deliver superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability