Vacuum Consumable Arc Remelting (VAR) is a critical requirement for refining Ni-W-Co-Ta alloys because it provides deep purification and structural uniformity that initial melting processes cannot achieve alone. By utilizing a controlled electric arc in a vacuum, VAR eliminates microscopic defects to ensure the final material meets high-performance standards.

Core Takeaway While initial methods like Vacuum Induction Melting (VIM) create the base alloy, they often leave behind structural imperfections. VAR acts as the essential secondary refining step, effectively erasing porosity and segregation to produce a dense, chemically consistent ingot ready for advanced manufacturing.

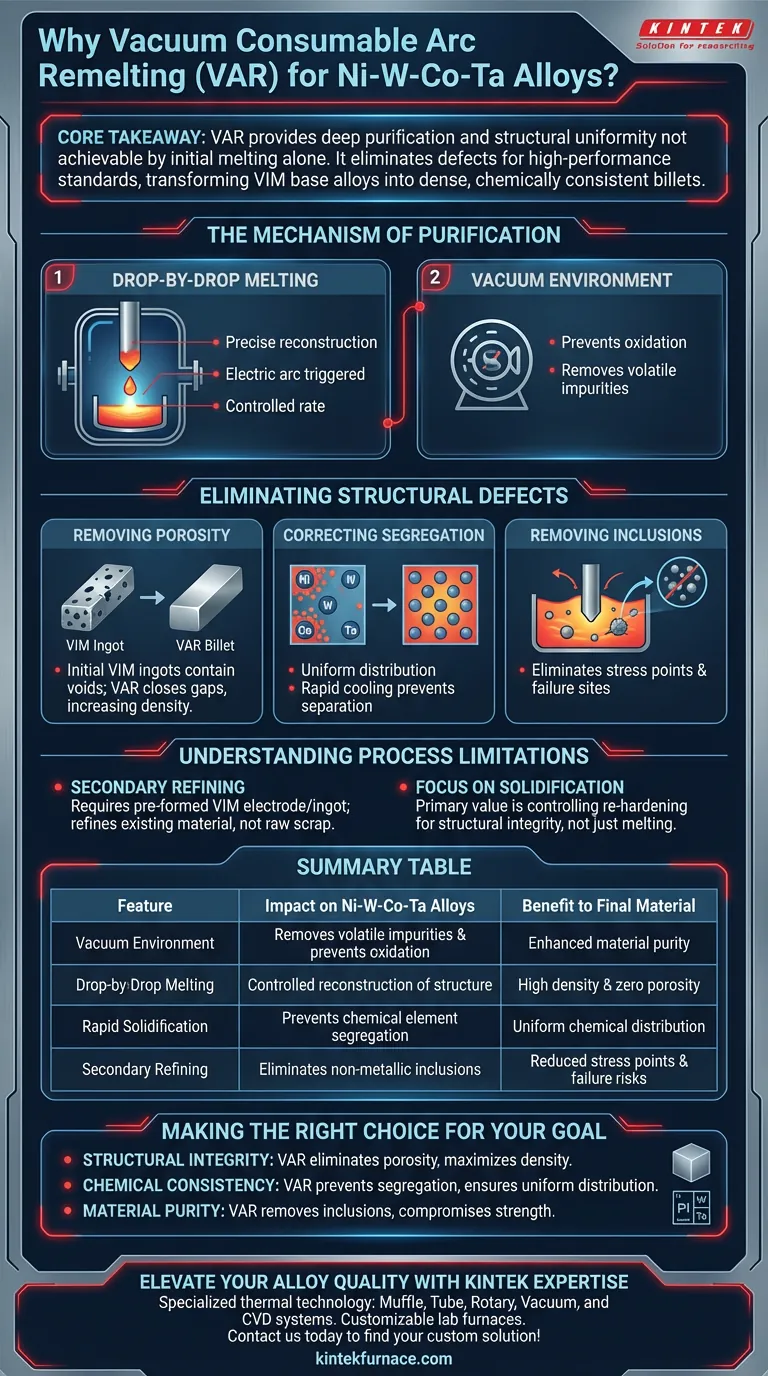

The Mechanism of Purification

Drop-by-Drop Melting

The VAR process refines the Ni-W-Co-Ta alloy through a precise drop-by-drop melting and condensation cycle.

Triggered by an electric arc, the alloy is melted slowly and methodically. This controlled rate allows for the careful reconstruction of the ingot structure.

The Vacuum Environment

This process occurs entirely within a vacuum chamber.

The vacuum environment is essential for preventing oxidation and removing volatile impurities that would otherwise degrade the alloy's performance.

Eliminating Structural Defects

Removing Porosity

One of the primary reasons VAR is required is to eliminate porosity.

Initial ingots from Vacuum Induction Melting (VIM) often contain microscopic voids or gas pockets. VAR remelting closes these gaps, significantly increasing the alloy's density.

Correcting Segregation

Ni-W-Co-Ta alloys are complex mixtures, and elements can separate or "segregate" during initial cooling.

VAR ensures uniform distribution of these elements. The rapid cooling of the molten drops prevents the chemical components from separating, ensuring a consistent structure throughout the ingot.

Removing Inclusions

The process effectively removes non-metallic inclusions.

These impurities, which act as stress points and potential failure sites, are isolated and eliminated during the remelting process.

Understanding the Process Limitations

Dependency on Pre-Melting

It is important to note that VAR is a secondary refining process, not a primary melting technique.

It relies on the existence of a pre-formed electrode or ingot, typically produced via VIM. It refines existing material rather than creating new alloys from raw scrap.

Focus on Solidification

The primary value of VAR lies in controlling solidification, not just melting.

While it excels at cleaning the material, its main function is to dictate how the ingot re-hardens to ensure the structural integrity required for subsequent processing.

Making the Right Choice for Your Goal

To determine if VAR is necessary for your specific application of Ni-W-Co-Ta alloys, consider your quality requirements:

- If your primary focus is Structural Integrity: VAR is non-negotiable for eliminating porosity and maximizing the density of the final billet.

- If your primary focus is Chemical Consistency: Use VAR to prevent segregation and ensure the Nickel, Tungsten, Cobalt, and Tantalum are uniformly distributed.

- If your primary focus is Material Purity: VAR is required to remove non-metallic inclusions that could compromise the alloy's strength.

Ultimately, VAR transforms a standard cast ingot into a high-quality billet capable of withstanding rigorous downstream processing.

Summary Table:

| Feature | Impact on Ni-W-Co-Ta Alloys | Benefit to Final Material |

|---|---|---|

| Vacuum Environment | Removes volatile impurities & prevents oxidation | Enhanced material purity |

| Drop-by-Drop Melting | Controlled reconstruction of ingot structure | High density & zero porosity |

| Rapid Solidification | Prevents chemical element segregation | Uniform chemical distribution |

| Secondary Refining | Eliminates non-metallic inclusions | Reduced stress points & failure risks |

Elevate Your Alloy Quality with KINTEK Expertise

Precision in Ni-W-Co-Ta refining demands high-performance thermal technology. At KINTEK, we provide the specialized equipment needed to transform raw ingots into high-integrity billets. Backed by expert R&D and world-class manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces tailored to your unique metallurgical needs.

Ready to eliminate structural defects and achieve superior chemical consistency? Contact us today to find your custom solution!

Visual Guide

References

- Yong Li, Chunxu Wang. Effect of Aging Time on Microstructure and Properties of Cold-Rolled Ni-W-Co-Ta Medium–Heavy Alloy. DOI: 10.3390/coatings14020230

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of a Vertical/Bottom Loading Vacuum Furnace? Save Space and Boost Precision

- How does increasing the vacuum furnace annealing temperature to 900 K adversely affect Ti–TEG composites?

- Why use low-speed heating (600-700°C) in Al-Ti-Zr sintering? Mastering Aluminum Phase Transition for Success.

- Why is maintaining a high vacuum environment essential during the liquid phase sintering of Fe-Cu composites?

- Why is vacuum-pressure treatment equipment required for deep wood impregnation? Unlock Ultimate Material Durability

- What are some common applications of vacuum chamber furnaces? Unlock High-Purity Material Transformations

- What role does an industrial high-temperature vacuum furnace play in the post-treatment of semiconductor nanocrystals?

- What is the typical working vacuum degree for most heat treatment vacuum furnaces? Optimize Your Process with the Right Vacuum Level