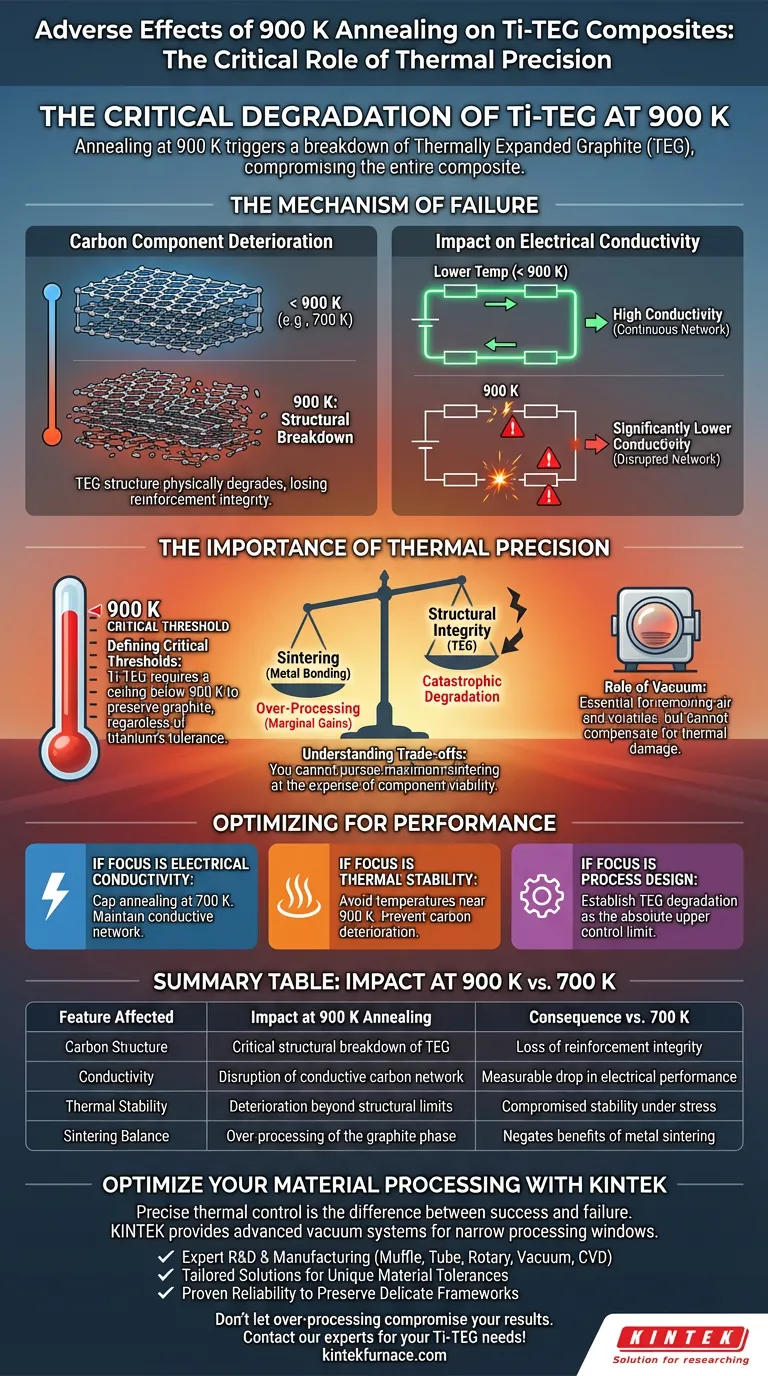

Annealing Titanium Hydride–Thermally Expanded Graphite (Ti–TEG) composites at 900 K triggers a critical degradation of the carbon structure. While elevated temperatures are typically used to encourage sintering between metal particles, 900 K pushes the Thermally Expanded Graphite (TEG) component beyond its structural limits. This thermal overshoot causes the carbon framework to deteriorate, resulting in compromised thermal stability and a measurable drop in electrical conductivity compared to samples annealed at lower temperatures, such as 700 K.

Optimal composite processing is a balancing act between the heat required for atomic diffusion and the thermal tolerance of the most sensitive component. For Ti-TEG composites, 900 K exceeds the resilience of the graphite phase, negating the benefits of improved sintering.

The Mechanism of Structural Failure

Carbon Component Deterioration

The primary adverse effect of heating to 900 K is the structural breakdown of the Thermally Expanded Graphite (TEG).

TEG relies on a specific lattice structure to provide its unique properties.

At 900 K, the material crosses a critical threshold where the carbon component begins to physically degrade, losing the integrity required to function as an effective reinforcement in the composite.

Impact on Electrical Conductivity

The physical damage to the TEG structure directly correlates to a loss in performance.

Samples annealed at 900 K exhibit significantly lower electrical conductivity than those processed at 700 K.

This indicates that the continuity of the conductive carbon network has been disrupted by the excessive thermal load.

The Importance of Thermal Precision

Defining Critical Thresholds

Vacuum furnace treatments must adhere to the specific tolerance limits of every material in the matrix.

Just as precise temperature control is required to prevent diamond degradation in copper composites or brittle phase formation in aluminum alloys, Ti-TEG requires a ceiling below 900 K to preserve the graphite.

Exceeding this limit damages the filler material (TEG) even if the matrix (Titanium Hydride) could theoretically withstand higher heat.

The Role of Vacuum Environments

While the temperature at 900 K is destructive, the vacuum environment itself remains essential for composite quality.

Vacuum processing helps eliminate air and volatiles trapped between laminate layers, reducing internal porosity.

However, the benefits of a high-vacuum environment—such as oxidation prevention and improved density—cannot compensate for the structural damage caused by overheating the TEG component.

Understanding the Trade-offs

Sintering vs. Structural Integrity

There is a fundamental conflict when processing Ti-TEG composites at high temperatures.

Higher temperatures generally promote better sintering and bonding between Titanium Hydride particles.

However, you cannot pursue maximum sintering at the expense of component viability. At 900 K, the marginal gains in particle sintering are rendered irrelevant by the catastrophic degradation of the TEG's functional properties.

The Risk of "Over-Processing"

It is a common pitfall to assume that higher temperatures always yield better density or bonding.

In multi-material composites, the processing window is often narrow.

Pushing the temperature to 900 K represents "over-processing," where the energy input destroys the material architecture rather than strengthening it.

Making the Right Choice for Your Goal

To optimize the performance of Ti-TEG composites, you must prioritize the preservation of the carbon structure over aggressive sintering temperatures.

- If your primary focus is Electrical Conductivity: Cap your annealing temperature at 700 K to maintain the integrity of the conductive carbon network.

- If your primary focus is Thermal Stability: Avoid temperatures near 900 K, as the deterioration of the carbon component will compromise the composite's ability to remain stable under thermal stress.

- If your primary focus is Process Design: Establish the degradation point of TEG as your absolute upper control limit, regardless of the sintering requirements of the titanium matrix.

Success in composite fabrication depends not just on achieving high density, but on respecting the thermal limits of the most fragile constituent in the mix.

Summary Table:

| Feature Affected | Impact at 900 K Annealing | Consequence vs. 700 K |

|---|---|---|

| Carbon Structure | Critical structural breakdown of TEG | Loss of reinforcement integrity |

| Conductivity | Disruption of conductive carbon network | Measurable drop in electrical performance |

| Thermal Stability | Deterioration beyond structural limits | Compromised stability under stress |

| Sintering Balance | Over-processing of the graphite phase | Negates benefits of metal sintering |

Optimize Your Material Processing with KINTEK

Precise thermal control is the difference between a high-performance composite and structural failure. KINTEK provides advanced, customizable vacuum systems designed to hit narrow processing windows with absolute accuracy.

Our value to you:

- Expert R&D & Manufacturing: Precision-engineered Muffle, Tube, Rotary, Vacuum, and CVD systems.

- Tailored Solutions: All high-temp lab furnaces are customizable to your unique material tolerances.

- Proven Reliability: Preserve delicate carbon frameworks and conductive networks with industry-leading thermal stability.

Don't let over-processing compromise your results. Contact our experts today to find the perfect furnace for your Ti-TEG and high-tech material needs!

Visual Guide

References

- M. Yakymchuk, E. G. Len. Structure and Electronic Properties of Composite Hydrogenated Titanium–Thermally Expanded Graphite Before and After Vacuum Furnace Annealing. DOI: 10.15407/mfint.45.09.1041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What industries commonly use vacuum chamber furnaces? Essential for Aerospace, Medical, and More

- Why is a high vacuum system critical for sealing the quartz tube used in Fe3GeTe2 single crystal preparation?

- What are the advantages of using a vacuum furnace for heat treatment? Achieve Superior Process Control and Clean Results

- What are the advantages of using an industrial vacuum oven for biomass powders? Maximize Quality & Chemical Stability

- What are the challenges of maintaining a high vacuum in furnaces? Overcome Key Hurdles for Optimal Performance

- What factors are critical for the design and selection of a vacuum furnace heating element? Optimize for Performance & Longevity

- How do custom vacuum furnaces ensure precise temperature control? Achieve Superior Thermal Uniformity for Your Lab

- What role do vacuum furnaces play in semiconductor wafer processing? Essential for Purity and Performance