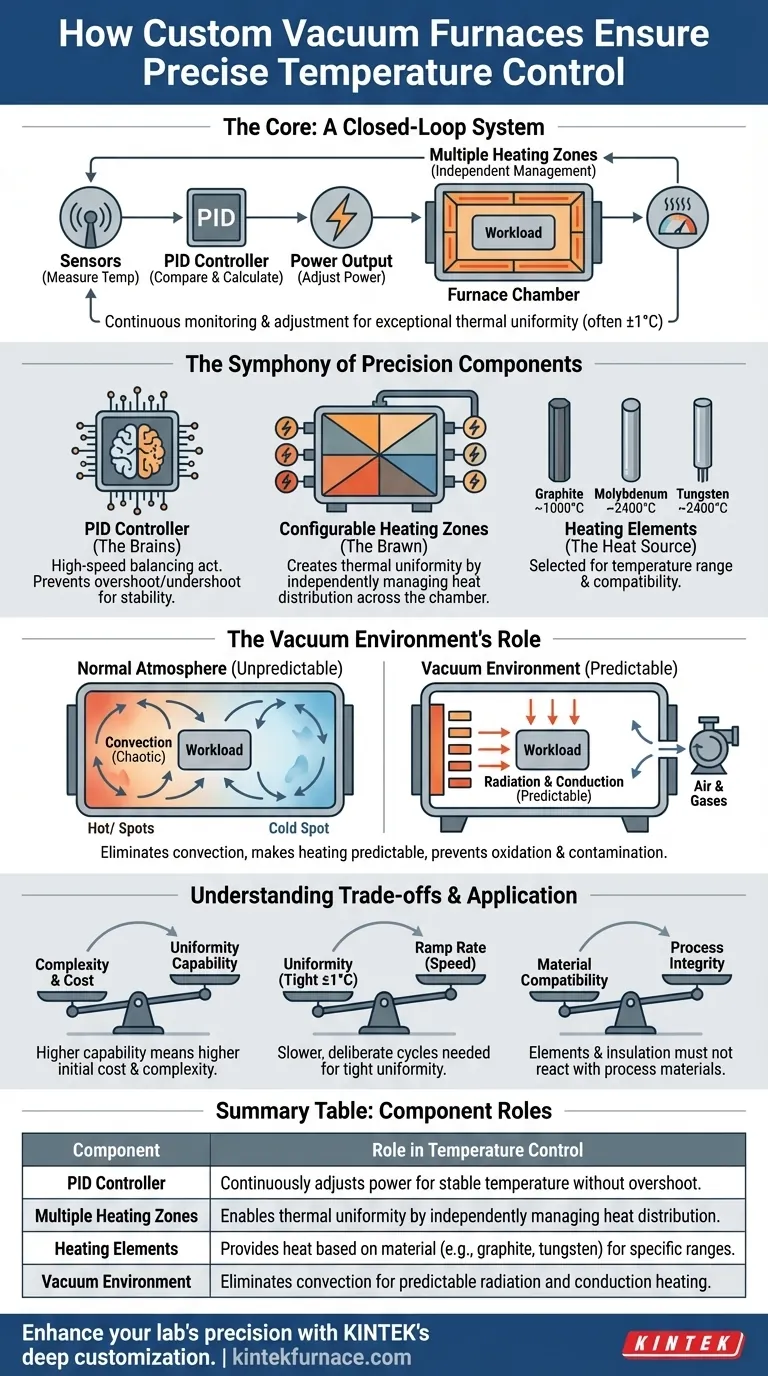

At its core, a custom vacuum furnace achieves precise temperature control through the integration of advanced electronic control systems, strategically designed heating elements, and multiple, independently managed heating zones. This multi-faceted approach allows the system to not only reach a target temperature but also to maintain exceptional thermal uniformity across the entire workload, often to within ±1°C.

The key to understanding furnace precision is realizing it's a closed-loop system. The furnace constantly measures its internal temperature, compares it to the desired setpoint, and makes immediate, minute adjustments to power output across different heating zones to maintain perfect equilibrium.

The Core Components of Temperature Precision

True temperature control is not the result of a single component, but a symphony of hardware and software working in concert. Each part plays a critical role in achieving the desired thermal profile.

The Control System: The Brains of the Operation

The heart of modern temperature control is the PID (Proportional-Integral-Derivative) controller. This is the furnace's brain, performing a constant, high-speed balancing act.

Think of it like an advanced cruise control system for your car. It doesn't just turn the power on or off; it continuously modulates it. The PID controller measures the current temperature, compares it to your setpoint, and calculates the precise power adjustment needed to correct any deviation, ensuring stability without overshooting or undershooting the target.

Configurable Heating Zones: The Brawn

A custom furnace doesn't use one giant heater. Instead, it divides its chamber into multiple configurable heating zones, each powered and controlled independently by the PID system.

This design is crucial for achieving thermal uniformity. Heat naturally dissipates unevenly, especially near the chamber doors or feedthroughs. By delivering slightly more power to cooler zones and less to hotter ones, the furnace can create a remarkably consistent temperature environment across a large three-dimensional space.

Heating Elements: The Source of the Heat

The choice of heating element material directly impacts the furnace's performance range and suitability for specific processes.

Common materials like graphite, molybdenum, and tungsten are selected based on the required maximum temperature and chemical compatibility. Tungsten, for example, is used for extreme temperatures up to 2400°C, while graphite is a versatile and common choice for many high-temperature applications.

How the Vacuum Environment Enables Precision

The vacuum itself is a critical part of the equation. By removing air and other gases, the environment fundamentally changes how heat behaves, making it more predictable and controllable.

Eliminating Unpredictable Convection

In a normal atmosphere, heat moves through convection—the circulation of hot air. This process is chaotic and creates hot and cold spots. In a vacuum, convection is eliminated.

Heat transfer is reduced to radiation (from the heating elements) and conduction (through direct contact). This makes the heating process far more predictable and allows the control system to manage temperature with much greater accuracy.

Preventing Contamination and Oxidation

The vacuum environment is essential for protecting the materials being processed. It removes oxygen and other reactive gases, which prevents oxidation and contamination that would otherwise occur at high temperatures.

This ensures that the final product's material properties are a result of the thermal process alone, uncompromised by unwanted chemical reactions.

Understanding the Trade-offs

Specifying a custom vacuum furnace involves balancing performance requirements with practical constraints. There is no single "best" configuration for all applications.

Complexity vs. Cost

A furnace with more independent heating zones and a more sophisticated control system will deliver superior uniformity. However, this increased capability comes with higher initial cost, greater programming complexity, and more potential points of failure.

Uniformity vs. Ramp Rate

Achieving extremely tight temperature uniformity (e.g., ±1°C) often requires slower, more deliberate heating and cooling cycles. Attempting to ramp the temperature up or down too quickly can introduce thermal gradients that undermine uniformity, as different parts of the workload absorb and release heat at different rates.

Material and Process Compatibility

The heating elements and insulation materials must be chemically compatible with the materials being processed. Certain elements can outgas or react with specific process materials, compromising the integrity of both the furnace and the product.

Making the Right Choice for Your Goal

Your specific application dictates which features of a vacuum furnace are most critical.

- If your primary focus is maximum thermal uniformity for sensitive parts like aerospace components: Prioritize a furnace with a high number of independently controlled heating zones and a proven PID control system.

- If your primary focus is processing highly reactive materials like semiconductor wafers: Your emphasis should be on the quality of the vacuum system (e.g., diffusion or molecular pumps) in addition to precise temperature control.

- If your primary focus is high-temperature metallurgy or material synthesis: The choice of heating element (e.g., tungsten, molybdenum) and hot zone insulation becomes the most critical factor to ensure the furnace can safely and reliably reach your target temperatures.

Understanding these individual components empowers you to specify a furnace that is not just capable, but perfectly suited to your exact process requirements.

Summary Table:

| Component | Role in Temperature Control |

|---|---|

| PID Controller | Continuously adjusts power for stable temperature without overshoot |

| Multiple Heating Zones | Enables thermal uniformity by independently managing heat distribution |

| Heating Elements | Provides heat based on material (e.g., graphite, tungsten) for specific temperature ranges |

| Vacuum Environment | Eliminates convection for predictable radiation and conduction heating |

Ready to enhance your lab's precision with a custom vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how we can help you achieve superior temperature control and thermal uniformity!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties