Vacuum chamber furnaces are a cornerstone of modern high-performance manufacturing. They are indispensable in industries where material integrity is paramount, including aerospace, medical, automotive, and electronics. The common thread is the need for an ultra-clean, controlled environment to heat-treat materials, which is impossible to achieve in a standard atmosphere.

The critical insight is that a vacuum furnace is not just a heater; it is a tool for environmental control. By removing atmospheric gases, it eliminates the risk of contamination and unwanted chemical reactions, enabling the creation of components with superior strength, purity, and performance.

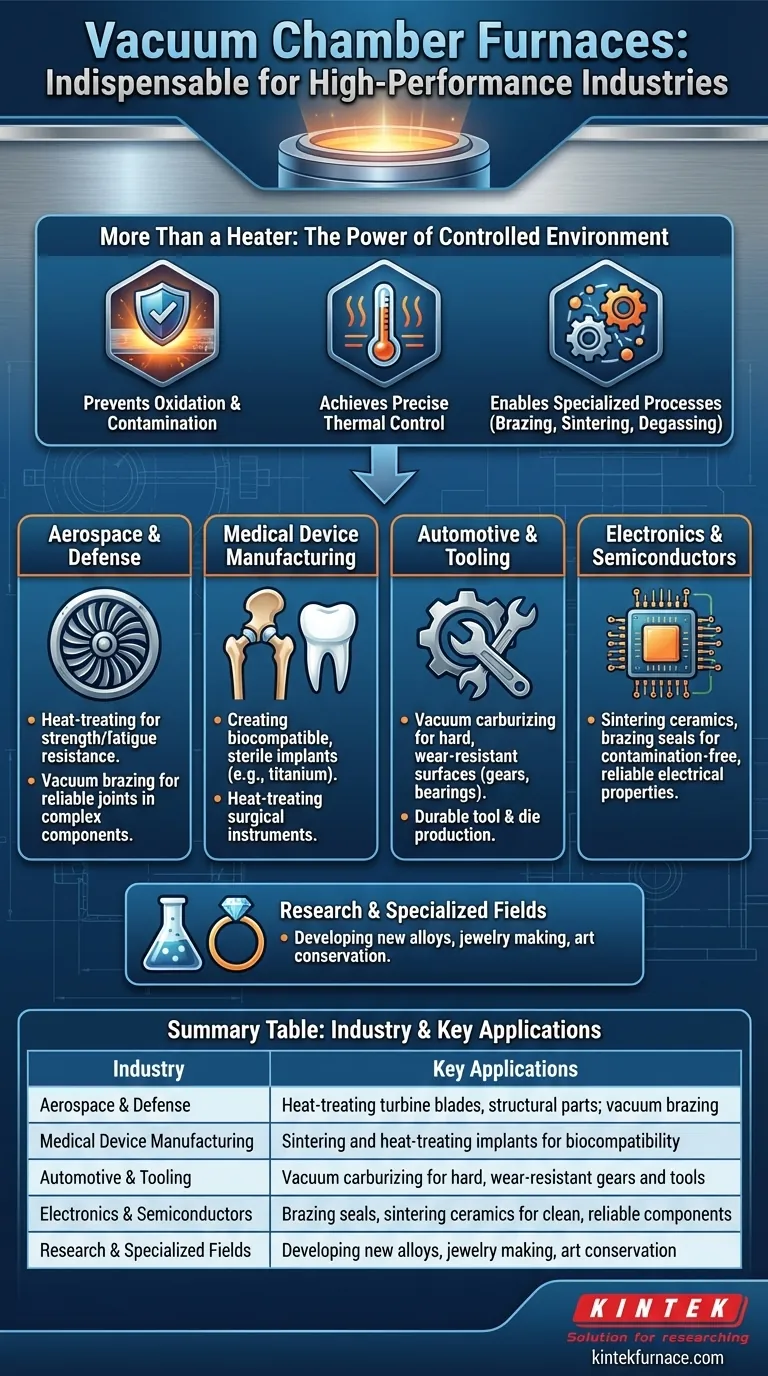

Why a Vacuum is a Critical Manufacturing Tool

Before listing the industries, it's essential to understand what problem a vacuum solves. When a material is heated in the open air, it reacts with oxygen, nitrogen, and water vapor, leading to oxidation (rusting or scaling), discoloration, and unpredictable changes in its properties. A vacuum furnace removes these variables.

Preventing Contamination and Oxidation

The primary function of the vacuum is to create a near-perfectly clean environment. By pumping out the air, you prevent reactive gases from coming into contact with the hot material.

This is crucial for high-performance metals like titanium and superalloys, which would be severely weakened by oxidation at high temperatures. The result is a clean, bright part with no surface contamination.

Achieving Precise Thermal Control

A vacuum provides a highly stable environment for heating and cooling. Without air currents creating hot and cold spots, heat is transferred primarily through radiation, allowing for extremely uniform temperature across the entire part.

This precision is vital for processes like annealing and tempering, where exact temperature profiles determine the final strength, hardness, and ductility of the material.

Enabling Specialized Processes

Certain manufacturing processes are only effective or possible in a vacuum. These include:

- Vacuum Brazing: Joining metals with a filler material. The vacuum prevents oxides from forming on the surfaces, ensuring an exceptionally strong and clean bond without the need for corrosive fluxes.

- Sintering: Fusing powdered materials (like in metal injection molding) into a solid mass. A vacuum prevents contamination that would weaken the final product.

- Degassing: Removing trapped gases from within a material, which improves its structural integrity and performance.

Key Industries and Their Applications

The need for purity and control drives the adoption of vacuum furnaces across several critical sectors.

Aerospace and Defense

This industry relies on high-strength, lightweight alloys for components that operate under extreme stress, such as jet engine turbine blades, structural frames, and landing gear.

Vacuum heat treatment ensures these parts possess the required mechanical properties and fatigue resistance, while vacuum brazing is used to assemble complex engine components with unparalleled reliability.

Medical Device Manufacturing

For medical implants like artificial joints and dental roots, material purity is non-negotiable. The human body can reject materials with even minor surface contaminants.

Vacuum furnaces are used to heat-treat and sinter materials like titanium and stainless steel, creating biocompatible, sterile, and durable implants. They are also used to harden and temper high-grade surgical instruments.

Automotive and Tooling

While cost is a major driver in the automotive world, vacuum furnaces are essential for high-performance components. Processes like vacuum carburizing create an extremely hard, wear-resistant surface on gears, shafts, and bearings.

This "case hardening" process results in parts that can withstand immense friction and stress, improving vehicle reliability and lifespan. Similarly, tool and die manufacturing uses vacuum hardening to produce durable, long-lasting tools.

Electronics and Semiconductors

The electronics industry requires microscopic precision and absolute cleanliness. Vacuum furnaces are used for sintering ceramic insulators, brazing metal-to-ceramic seals, and annealing components in a contaminant-free environment.

This ensures that the electrical properties of the components are not compromised and that the tiny, intricate joints are strong and reliable.

Research and Specialized Fields

Beyond mass manufacturing, vacuum furnaces are a vital tool in research and development for creating new alloys and studying material behavior. Other niche applications include jewelry making, where vacuum induction melting produces high-purity precious metals, and even art conservation, for the gentle heat treatment of delicate artifacts.

Understanding the Trade-offs

While powerful, vacuum furnaces are not a universal solution. Their benefits come with clear and important trade-offs.

Cost and Complexity

Vacuum furnaces are significantly more expensive to purchase and operate than their atmospheric counterparts. The systems require sophisticated vacuum pumps, seals, controls, and instrumentation, all of which add to the initial investment and energy consumption.

Slower Cycle Times

The process of pumping a chamber down to a deep vacuum takes time. This step, along with the controlled backfilling or cooling process, can result in longer overall cycle times compared to simply heating a part in a conventional oven.

Maintenance Requirements

The vacuum system is the heart of the furnace and demands rigorous maintenance. Seals, pumps, and gauges must be regularly inspected and serviced to prevent leaks, which would compromise the entire process and lead to scrapped parts.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace is driven by the final requirements of the component.

- If your primary focus is ultimate material purity and performance (e.g., aerospace, medical implants): A high-vacuum furnace is non-negotiable to eliminate any risk of atmospheric reaction.

- If your primary focus is clean and strong joining of complex parts (e.g., automotive heat exchangers, electronic components): Vacuum brazing offers superior joint quality and cleanliness compared to atmospheric methods.

- If your primary focus is enhancing the surface properties of steel parts (e.g., tools, gears): Vacuum heat treating and carburizing provide precise control over hardness and wear resistance without surface oxidation.

- If your primary focus is cost-effective bulk processing where cleanliness is a factor but not absolute: A low-vacuum or controlled atmosphere furnace may provide a sufficient balance of quality and throughput.

Ultimately, adopting vacuum furnace technology is a strategic decision to control the material environment, thereby guaranteeing the final component's integrity and performance.

Summary Table:

| Industry | Key Applications |

|---|---|

| Aerospace & Defense | Heat-treating turbine blades, structural parts; vacuum brazing for reliable joints |

| Medical Device Manufacturing | Sintering and heat-treating implants like titanium joints for biocompatibility |

| Automotive & Tooling | Vacuum carburizing for hard, wear-resistant gears and tools |

| Electronics & Semiconductors | Brazing seals, sintering ceramics for clean, reliable components |

| Research & Specialized Fields | Developing new alloys, jewelry making, art conservation |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is enhanced by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, medical, automotive, or electronics, we deliver reliable, contamination-free performance. Contact us today to discuss how our furnaces can optimize your processes and ensure superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity