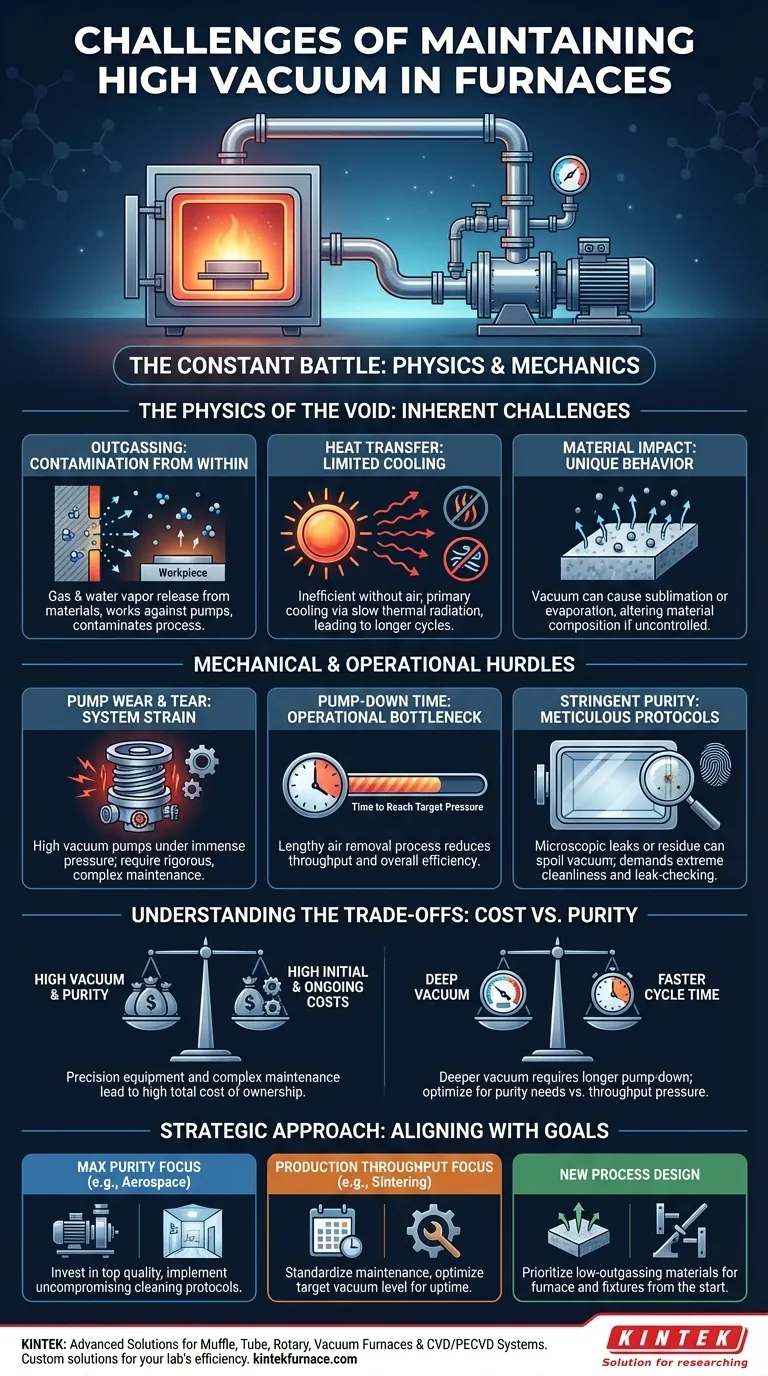

The primary challenges of maintaining a high vacuum in a furnace are a constant battle against physics and mechanics. The core difficulties stem from material outgassing which contaminates the vacuum, the inherent inefficiency of heat transfer in a void, the relentless wear on pumping equipment, and the significant operational time and cost required to achieve and hold these extreme conditions.

Maintaining a high vacuum is not a "set and forget" operation. It is an active process of managing a delicate equilibrium against contamination from within the furnace itself, the physical limitations of heat transfer, and the mechanical realities of high-performance equipment.

The Physics of the Void: Inherent Challenges

Achieving and holding a high vacuum means fighting against the natural tendencies of materials and energy. The difficulty begins at the molecular level.

The Constant Battle Against Outgassing

Even in a perfectly sealed chamber, the vacuum level is under constant assault from outgassing. This is the process where molecules of gas and water vapor trapped within the furnace walls, fixtures, and even the workpiece itself are released into the vacuum.

This released gas directly works against the vacuum pumps and can contaminate the process, potentially leaving residue on or altering the properties of the material being treated.

The Problem of Heat Transfer

In a normal atmosphere, heat is transferred efficiently through convection (movement of hot air) and conduction. In a high vacuum, these methods are severely limited due to the lack of air molecules.

This leaves thermal radiation as the primary means of cooling. Radiative cooling is significantly slower, leading to longer cycle times as you wait for the furnace and its contents to cool down.

The Impact on Materials

A high vacuum is not a neutral environment. The absence of atmospheric pressure and components like oxygen and nitrogen can cause materials to behave in unique ways.

This is often the desired effect, such as preventing oxidation. However, it can also promote the sublimation or evaporation of certain elements from an alloy, altering its composition in unintended ways if not properly controlled.

Mechanical and Operational Hurdles

Beyond the physics, the machinery and procedures required for high vacuum present their own set of significant challenges. These are the practical, day-to-day realities of operating a high vacuum furnace.

Continuous Pump Wear and Tear

High vacuum pumps, especially turbomolecular and diffusion pumps, are sophisticated pieces of machinery that are prone to wear when operating for extended periods.

Sustaining the pressure differential required for a high vacuum puts immense strain on these systems, necessitating a rigorous and often complex maintenance schedule to prevent failure.

The Time Cost of Pump-Down

Achieving a high vacuum is not an instantaneous process. The pump-down time—the duration it takes to remove air molecules from the chamber to reach the target pressure—can be lengthy.

This long lead time for each cycle directly impacts operational throughput and efficiency, creating a bottleneck in many production environments.

The Stringent Need for Purity

The entire system must be impeccably clean and perfectly sealed. A microscopic leak, a fingerprint on an internal surface, or residual cleaning fluid can introduce enough vapor to spoil the vacuum level.

This demands meticulous cleaning protocols and regular leak-checking, adding to the complexity and time required for proper maintenance.

Understanding the Trade-offs: Cost vs. Purity

The benefits of a high vacuum environment—purity, densification, and control—come at a price. Understanding these trade-offs is critical for any operation.

High Initial and Ongoing Costs

High vacuum furnaces and their associated pumping systems are precision-engineered and therefore carry a high initial equipment cost.

Furthermore, the complex maintenance, need for specialized parts, and potential for production downtime during service contribute to a high total cost of ownership.

Cycle Time vs. Required Vacuum Level

There is a direct trade-off between the depth of the vacuum and the process cycle time. A deeper, "harder" vacuum requires a significantly longer pump-down time.

For any given process, you must balance the required material purity against the economic pressure for faster cycle times and higher throughput. Pushing for a higher vacuum than necessary is an expensive waste of time.

Making the Right Choice for Your Goal

Your strategy for managing vacuum challenges should align directly with your primary objective.

- If your primary focus is maximum purity and process control (e.g., aerospace alloys, medical implants): Invest in the highest quality pumps and monitoring systems, and implement uncompromising cleaning and leak-detection protocols.

- If your primary focus is production throughput (e.g., general sintering or degassing): Standardize your preventative maintenance schedule to maximize uptime and carefully optimize the target vacuum level to minimize pump-down time.

- If you are designing a new process: Prioritize the selection of low-outgassing materials for both the furnace interior and your workpiece fixtures to reduce the vacuum load from the start.

Ultimately, mastering a high vacuum furnace means treating it not as a simple oven, but as a controlled environment where materials science, thermodynamics, and mechanical engineering must be managed in precise harmony.

Summary Table:

| Challenge | Key Issues | Impact |

|---|---|---|

| Outgassing | Gas release from materials | Contamination, reduced vacuum purity |

| Heat Transfer | Limited convection/conduction | Longer cooling cycles, inefficiency |

| Pump Wear | Strain on high-vacuum pumps | Frequent maintenance, downtime |

| Pump-Down Time | Slow air removal | Reduced throughput, higher costs |

| Purity Requirements | Need for cleanliness/sealing | Complex protocols, operational delays |

| Costs | High initial and ongoing expenses | Increased total cost of ownership |

Struggling with high vacuum furnace challenges? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise handling of outgassing, heat transfer, and pump maintenance to boost your lab's efficiency and reduce costs. Contact us today to discuss how we can tailor a furnace to meet your unique experimental needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance